RECLINE EXCITE: Service & Maintenance Manual - rev. 2.4

6.12.2. H

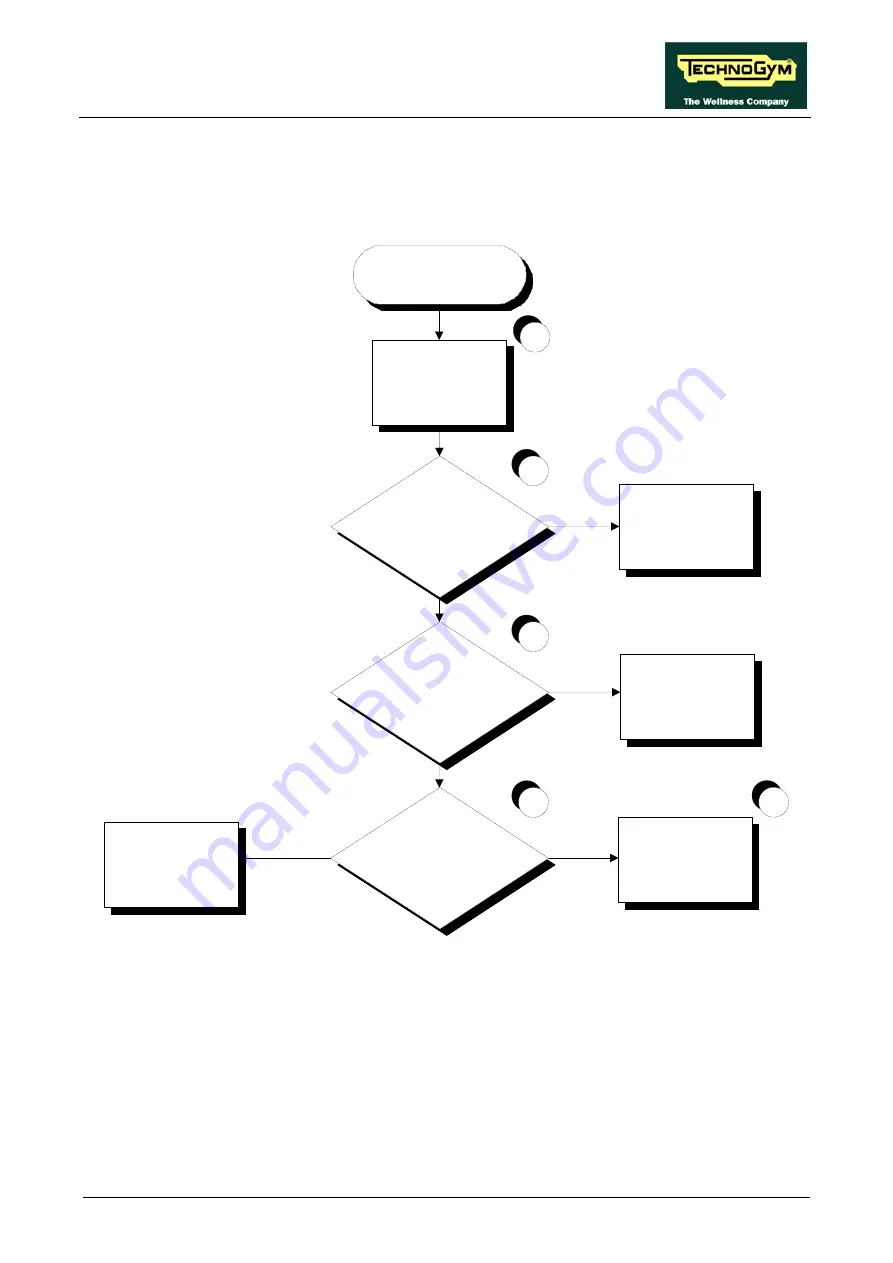

AND SENSOR

achine displays this error if the HS

The m

interface board is not working, or if it is not supplied by

is

the d play board.

THERE IS NO HR

SIGNAL

Are the sensors correctly

connected to the HS interf ace

board?

Is the supply v oltage correct at

the output of the display board?

Reinstate the connection

Check the connections

between the hand sensor

board and the display

Replace the display board

2

4

YES

NO

YES

NO

Is the supply v oltage correct at

the input to the HS interf ace

board?

Replace the HS interf ace

board

3

YES

NO

5

Check the earth connection

of the machine

1

Follow the procedure step by step to correctly diagnose the problem. Take particular care with the

checks highlighted by circled numbers, which are described in detail below:

(1)

Check the earthing of the machine using a tester to measure the resistance between the ground

pin on the power supply cable and the ground node to which the receiver is connected inside

the display. The value must be less than 1 Ohm.

(2)

Check the connections, referring to paragraph 2.9. “Cables”.

Page 6.29

Summary of Contents for Recline 500

Page 1: ...SERVICE MAINTENANCE MANUAL REV 2 4...

Page 2: ......

Page 4: ......

Page 10: ...RECLINE EXCITE Service Maintenance Manual rev 2 4 Page vi Page intentionally left blank...

Page 46: ...RECLINE EXCITE Service Maintenance Manual rev 2 4 Page 3 14 Page intentionally left blank...

Page 58: ...RECLINE EXCITE Service Maintenance Manual rev 2 4 Page 4 12 Page intentionally left blank...

Page 94: ...RECLINE EXCITE Service Maintenance Manual rev 2 4 Page 6 34 Page intentionally left blank...

Page 134: ...RECLINE EXCITE Service Maintenance Manual rev 2 4 Page 7 40 Page intentionally left blank...

Page 140: ...RECLINE EXCITE Service Maintenance Manual rev 2 4 Page 8 6 Page intentionally left blank...

Page 172: ...RECLINE EXCITE Service Maintenance Manual rev 2 4 Page 9 32 Page intentionally left blank...

Page 181: ......