RUN 600 XTPRO: Service & Maintenance Manual - rev. 1.3

Page 3.4

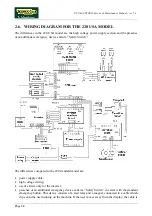

•

Hitachi J100

:

installed up until serial number 01000078;

•

Hitachi SJ100

: on actual production.

The inverter has a power of 1.5 KW (2 Hp).

3.1.9. I

NVERTER INTERFACE BOARD

Receives from the display an enable signal for the inverter and a PWM signal proportional to the

selected speed, and converts it into a continuous voltage for controlling the inverter. Receives the

error signal generated by the inverter in the event of problems and transmits it to the display.

Receives the low voltages output by the power supply and passes them to the display. There are 2

LEDs on the board:

•

DL1

: illuminates when the tread belt is moving;

•

DL2

: illuminates when the inverter does not detect any error conditions and therefore the alarm

signal is inactive.

3.1.10. E

LEVATION MOTOR

It is a DC motor which, by means of a mechanical reduction unit and a timing belt, turns the lead

screw nuts on the threaded elevation bars, causing the machine to be raised or lowered depending on

the direction of rotation.

3.1.11. P

HOTOCELL

This is the device which provides feedback on the motion of the elevation motor. It transmits one

pulse for each tooth detected on the encoder wheel which is fixed to the gearmotor, and a signal

indicating the direction of movement.

The photocell used on these machines is the

Optek OPB610

photocell mounted on circuit board

GF970711

.

3.1.12. E

LEVATION BOARD

Receives from the display the enable signal for elevation motion and converts it into a control for

the elevation motor. Generates its power supply and the DC power supply for the motor by means of

a transformer and rectifier bridge. Determines the motor position, and hence the treadmill elevation,

by means of the photocell. Generates and sends to the display a motion status signal at every 0.5%

variation in the elevation.

The SW version of the chip mounted on the board to be used is

RX50V1

and is identified by the

label on the chip.

It checks the lower and upper travel limits by means of 2 limit switches. The board includes 2 LEDs

associated to the limit switches, which are normally illuminated:

•

DL1

: comes off when the upper limit switch is tripped;

•

DL2

: comes off if the lower limit switch is tripped.

Summary of Contents for RUN 600 XTPRO

Page 1: ...SERVICE MAINTENANCE MANUAL REV 1 3...

Page 2: ......

Page 4: ......

Page 24: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 2 14 Page intentionally left blank...

Page 36: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 3 12 Page intentionally left blank...

Page 38: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 4 2 Page intentionally left blank...

Page 82: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 6 42 Page intentionally left blank...

Page 126: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 8 10 Page intentionally left blank...

Page 156: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 11 14 Page intentionally left blank...

Page 157: ......