RUN 600 XTPRO: Service & Maintenance Manual - rev. 1.3

Page 3.9

3.3. ELEVATION MOTOR DRIVE

3.3.1. M

ECHANICS

The elevation of the machine is varied by the elevation motor which, by means of a timing belt,

turns the lead screw nuts on the 2 elevation bars. The motor has an integral encoder wheel which, by

means of a photocell, provides the motor motion control signal: each motor revolution corresponds

to a predetermined number of pulses and to a predetermined displacement on the elevation bars.

The direction of rotation of the motor determines whether the treadmill moves upward or

downward.

3.3.2. T

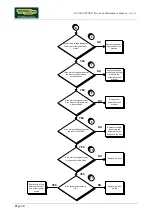

HE RESET PROCEDURE

On power-up, the machine performs a reset procedure in order to determine the reference incline.

The procedure consists of the following steps:

•

Downward movement of the machine until the lower limit switch is pressed. This is the

reference “zero position” for the incline: all the movements for reaching different elevations will

be variations referred to this reference.

•

Upward movement of the machine until the machine reaches the established 0.0% incline

position.

3.3.3. C

ONTROLS

To vary the incline, the CPU board sends the elevation board an Up signal (move motor in the up

direction to increase the elevation) or a Down signal (move motor in the down direction to decrease

the elevation). The elevation board accordingly actuates the motor the appropriate direction, by

supplying it with a positive or negative voltage. When the motor moves, the photocell generates the

pulses which are received by the elevation board. The elevation board counts the pulses received

and, when the number corresponds to a 0.5% variation in the incline, toggles the level of the Status

signal transmitted to the CPU board. The CPU board counts the number of Status signal transitions

received. When this value corresponds to the desired incline, it resets the Up or Down signal which

produced the movement.

During the reset at the start up, if after having asserted the Up or Down signal, the CPU board does

not receive any Status signal within a predetermined period of time (a few seconds), it resets the

asserted signal and displays error code “CAUTION = E5” to indicate absence of movement.

In that condition, the SW enables the machine to move the belt and shows on the display

the elevation of -0.5%.

Summary of Contents for RUN 600 XTPRO

Page 1: ...SERVICE MAINTENANCE MANUAL REV 1 3...

Page 2: ......

Page 4: ......

Page 24: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 2 14 Page intentionally left blank...

Page 36: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 3 12 Page intentionally left blank...

Page 38: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 4 2 Page intentionally left blank...

Page 82: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 6 42 Page intentionally left blank...

Page 126: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 8 10 Page intentionally left blank...

Page 156: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 11 14 Page intentionally left blank...

Page 157: ......