RUNRACE : Service & Maintenance Manual - rev. 2.0

Page 7.16

7.13. DISASSEMBLING THE MOTOR ROLLER

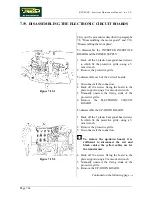

Figure 7.13-1

1. Raise the machine to its maximum incline

position.

2. Turn off the machine and unplug the mains

lead from the wall outlet.

To facilitate the subsequent adjustment

of the belt tension, after shifting the join

to the underside of the machine,

measure out a distance of 1 m on the belt

and mark its ends with a white marker

pen.

3. Carry out the procedure described in the

paragraph 7.8. “Disassembling the motor

guard” and 7.11. “Disassembling shield grid

for tread belt motor and inverter”.

4. Working from the lower part of the machine,

back off the screw

a

on each side using a 6-

mm hex T wrench.

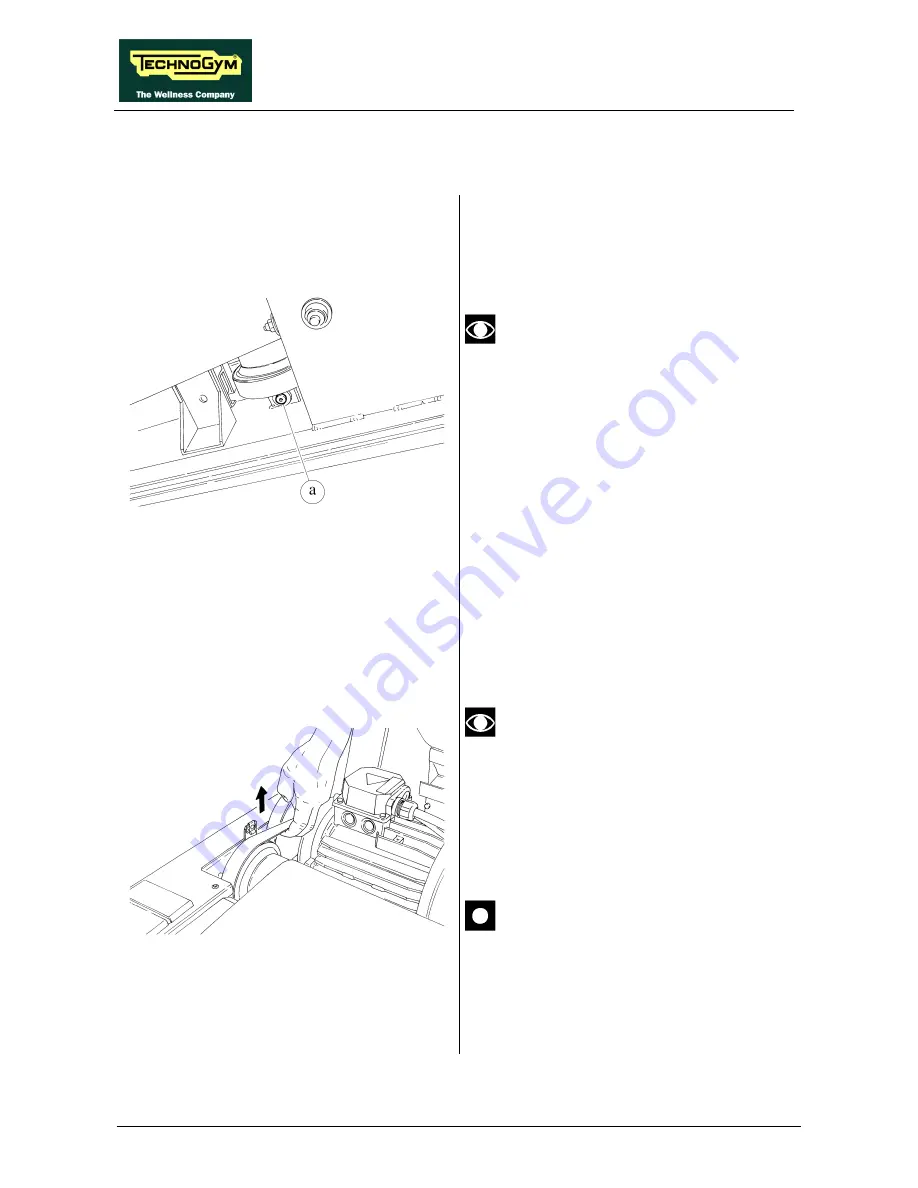

Figure 7.13-2

5. Pulling on the drive belt of the tread-belt

motor, lift the MOTOR ROLLER so that it

comes out of its support.

If it proves difficult to raise MOTOR

ROLLER, try loosening the belt tension

as described in paragraph 8.4. .

6. Remove the MOTOR ROLLER.

To reassemble the MOTOR ROLLER, carry out

the above steps in reverse order.

After completing the procedure, adjust

the centering and tension of the tread

belt as described in paragraphs 8.2. and

8.3. and adjust the alignment and

tension of the drive belt as described in

paragraph 8.4. .

Summary of Contents for Runrace

Page 1: ...SERVICE MAINTENANCE MANUAL REV 2 0 ...

Page 2: ......

Page 4: ......

Page 28: ...RUNRACE Service Maintenance Manual rev 2 0 Page 2 18 Page intentionally left blank ...

Page 144: ...RUNRACE Service Maintenance Manual rev 2 0 Page 8 12 Page intentionally left blank ...

Page 160: ...RUNRACE Service Maintenance Manual rev 2 0 Page 9 16 Page intentionally left blank ...

Page 182: ...RUNRACE Service Maintenance Manual rev 2 0 Page 11 16 Page intentionally left blank ...

Page 183: ......