STEPRACE: Service & Maintenance Manual - rev. 1.2

Page 7.17

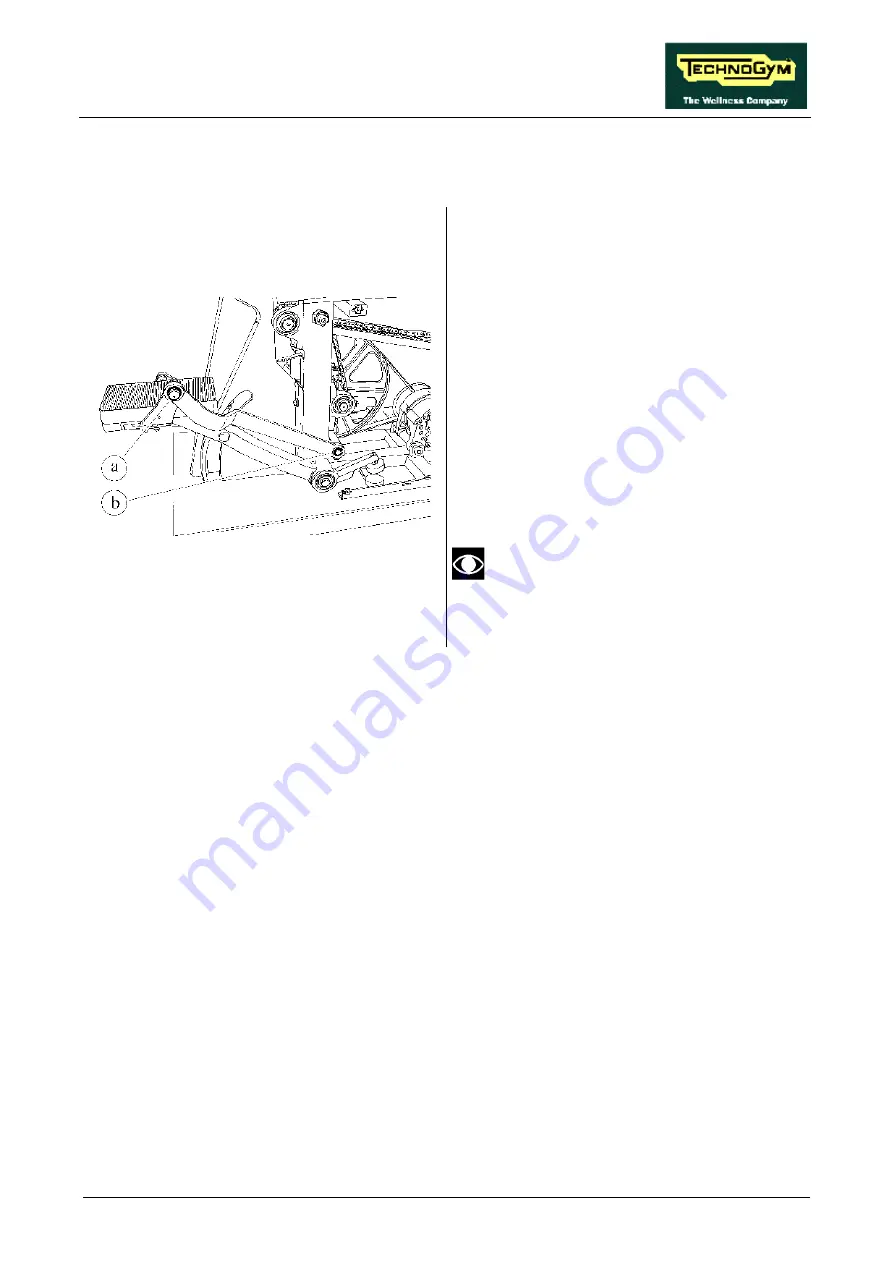

7.13. DISASSEMBLING THE PEDAL CONNECTING RODS

Figure 7.13-1

Carry out the procedures described in paragraph

7.8. “Disassembling the side guards”.

Working from both sides:

1. Remove the protective cap

a

.

2. Back off the screw underneath the cap using

a 17-mm wrench.

3. Back off screw

b

using a 17-mm wrench.

4. Remove the CONNECTING ROD.

To reassemble the PEDAL CONNECTING

RODS, carry out the above steps in reverse

order.

Before reassembling the CONNECTING

RODS, lubricate the bushings with a

thin layer of chain grease.

Summary of Contents for Steprace

Page 1: ...SERVICE MAINTENANCE MANUAL REV 1 2...

Page 2: ......

Page 4: ......

Page 8: ...STEPRACE Service Maintenance Manual rev 1 2 Page iv Page intentionally left blank...

Page 16: ...STEPRACE Service Maintenance Manual rev 1 2 Page 2 6 Page intentionally left blank...

Page 46: ...STEPRACE Service Maintenance Manual rev 1 2 Page 6 20 Page intentionally left blank...

Page 96: ...STEPRACE Service Maintenance Manual rev 1 2 Page 8 12 Page intentionally left blank...

Page 104: ...STEPRACE Service Maintenance Manual rev 1 2 Page 10 6 Page intentionally left blank...

Page 113: ......