SYNCHRO EXCITE Class & Trend: Service & maintenance manual - rev. 2.0

Page 3.7

3.1.7.

B

RAKE BOARD

There are 2 versions of the Brake Board, one which is used on the mains powered version and the

other on the self-powered version. In either case, the Brake Board consists of:

¾

Power supply section which generates the low voltages used by the machine: +5 Vdc and

+12 Vdc. Depending on the machine version, these voltages will be generated either from the

110 VAC or 220 VAC mains supply, or from the alternator-battery.

¾

Section for RS-485 serial communications with the Display Board for:

commands determining the resistance that is required of the brake;

brake error messages;

commands for modifying the circuit board configuration parameters;

commands for viewing the errors logged by the circuit board.

¾

Section which generates the current for the brake winding: varying the current produces a

proportional variation in the resistance of the brake. The excitation current supplied to the

brake is a function of the effort level selected on the display and the RPM value measured by

the speed sensor (angular velocity of the brake disk) and is determined by the values stored

in the braking table.

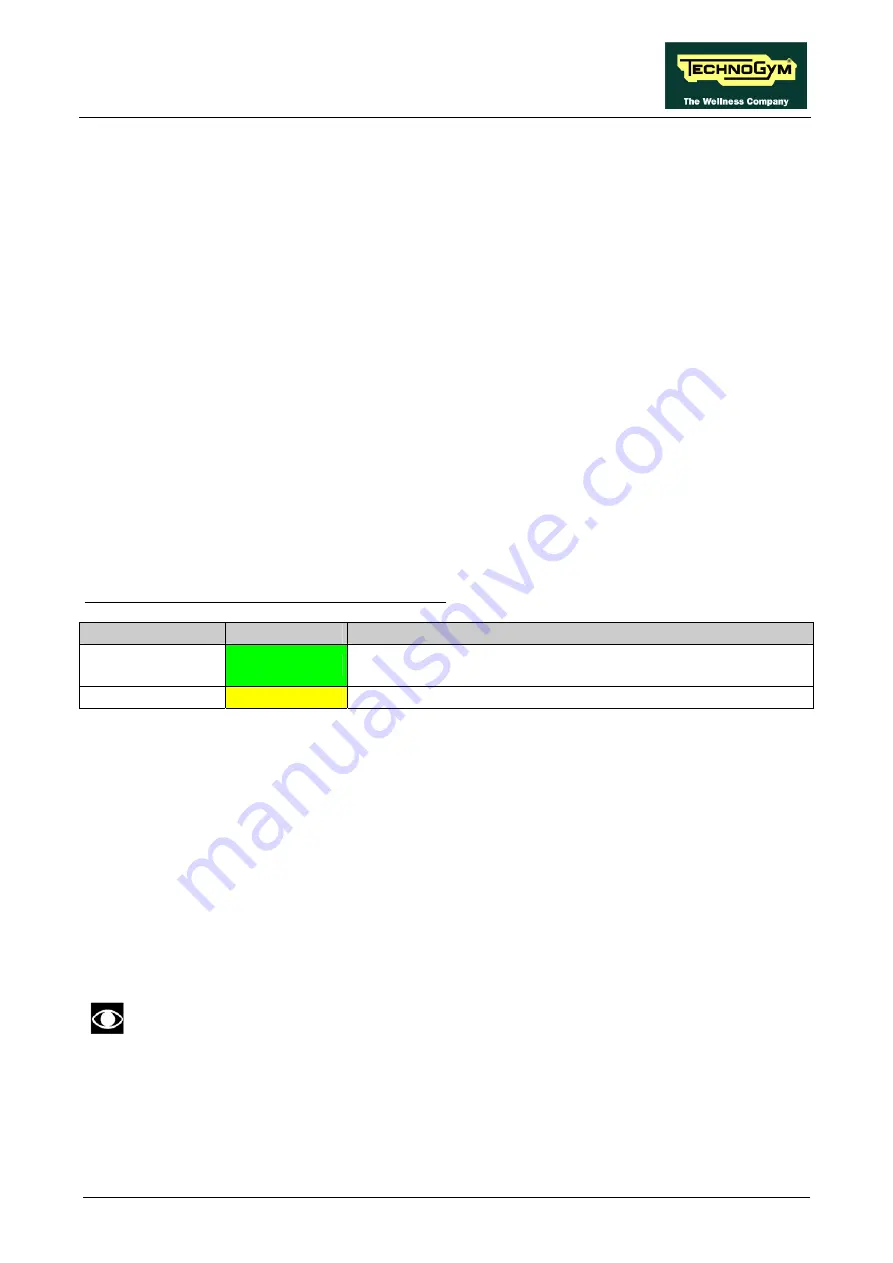

The board includes the following indicator LEDs:

LED name

Colour

Description

LED1

green

if ON the board is supplying the brake winding.

if BLINKING the Brake Board is in an error condition.

LED2

yellow

if ON there is the +5 Vdc supply from the circuit Board.

3.1.8.

B

RAKE

This is an eddy current brake, consisting of a flywheel mass and a flat copper disk that rotates in the

air gap of a winding. Variations in the winding current produce a change in the resulting field,

which consequently varies the eddy currents induced within the copper disk and hence its resistance

to movement.

The winding has a resistance of approximately 3.5

Ω

(Ohm).

A klixon thermal cut-out, installed directly on the winding, interrupts the circuit whenever it detects

a temperature exceeding 140°C.

3.1.9.

S

PEED SENSOR

Only for 500, 700 and 700WTV versions.

This consists of a magnetic induction sensor which detects the heads of the brake disk fixing screws.

On the self-powered machine, the speed sensor is directly built-in on the alternator (see paragraph

3.1.11. “Alternator”).

Summary of Contents for Synchro Excite 500

Page 1: ...SERVICE MAINTENANCE MANUAL REV 2 0 ...

Page 2: ......

Page 4: ......

Page 48: ...SYNCHRO EXCITE Class Trend Service maintenance manual rev 2 0 Pagina 4 6 LIBYA DVB T ...

Page 50: ......

Page 201: ......