SYNCHRO EXCITE Class & Trend: Service & maintenance manual - rev. 2.0

Pagina 6.32

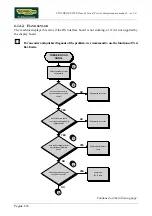

(1)

Carry out the “Standard Setting” procedure as detailed at paragraph 9.5.5. “Standard

settings”.

The speed sensor detects the heads of these bolts.

(2)

Powered models

:

Place the tester probes across the terminals of the speed sensor. The

measured signal should be that indicated in Figure 3.2-1. In addition,

when pedaling at 80 RPM the frequency of the signal should be 136

Hz.

Self-Powered models

: Check the signal on

ELT-01

cable. The measured signal should be

that indicated in Figure 3.2-1. In addition, when pedaling at 80 RPM

the frequency of the signal should be 136 Hz.

The speed signal can also be observed qualitatively, using a multimeter. The value should be 0

Vdc when the machine is stopped, and gradually increase as the speed increases.

(3)

Update the low kit SW uploading both firmware and brake table. At the end carry out the

“Default setting” procedure for the low kit parameters.

If you replace Display board/Brake board, check that its SW version is updated, otherwise

install the last version.

Summary of Contents for Synchro Excite 500

Page 1: ...SERVICE MAINTENANCE MANUAL REV 2 0 ...

Page 2: ......

Page 4: ......

Page 48: ...SYNCHRO EXCITE Class Trend Service maintenance manual rev 2 0 Pagina 4 6 LIBYA DVB T ...

Page 50: ......

Page 201: ......