SYNCHRO EXCITE Class & Trend: Service & maintenance manual - rev. 2.0

Pagina 7.2

7.1.2.

LED

V

ERSION

700

AND

700SP

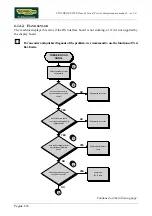

Figure 7.1-4

1.

Turn off the machine and unplug the mains

lead from the wall outlet

(Only for 700).

2.

Back off the 4 screws

(a)

using a medium

Phillips screwdriver.

Figure 7.1-5

3.

Unplug the connectors as indicated in the

figure at left [CN9-CN1-CN6-CN5-CN4].

4.

Remove the display.

Figure 7.1-6

5.

Back off the 2 screws

(b)

, using an 8mm Hex

wrench, to remove the rear display support.

To reassemble the display, carry out the above

steps in reverse order.

Summary of Contents for Synchro Excite 500

Page 1: ...SERVICE MAINTENANCE MANUAL REV 2 0 ...

Page 2: ......

Page 4: ......

Page 48: ...SYNCHRO EXCITE Class Trend Service maintenance manual rev 2 0 Pagina 4 6 LIBYA DVB T ...

Page 50: ......

Page 201: ......