VARIO : Service & maintenance manual- rev. 4.2

Page 7.26

7.7.

DISASSEMBLING THE GUARDS

7.7.1.

D

ISASSEMBLING THE CENTRE GUARD

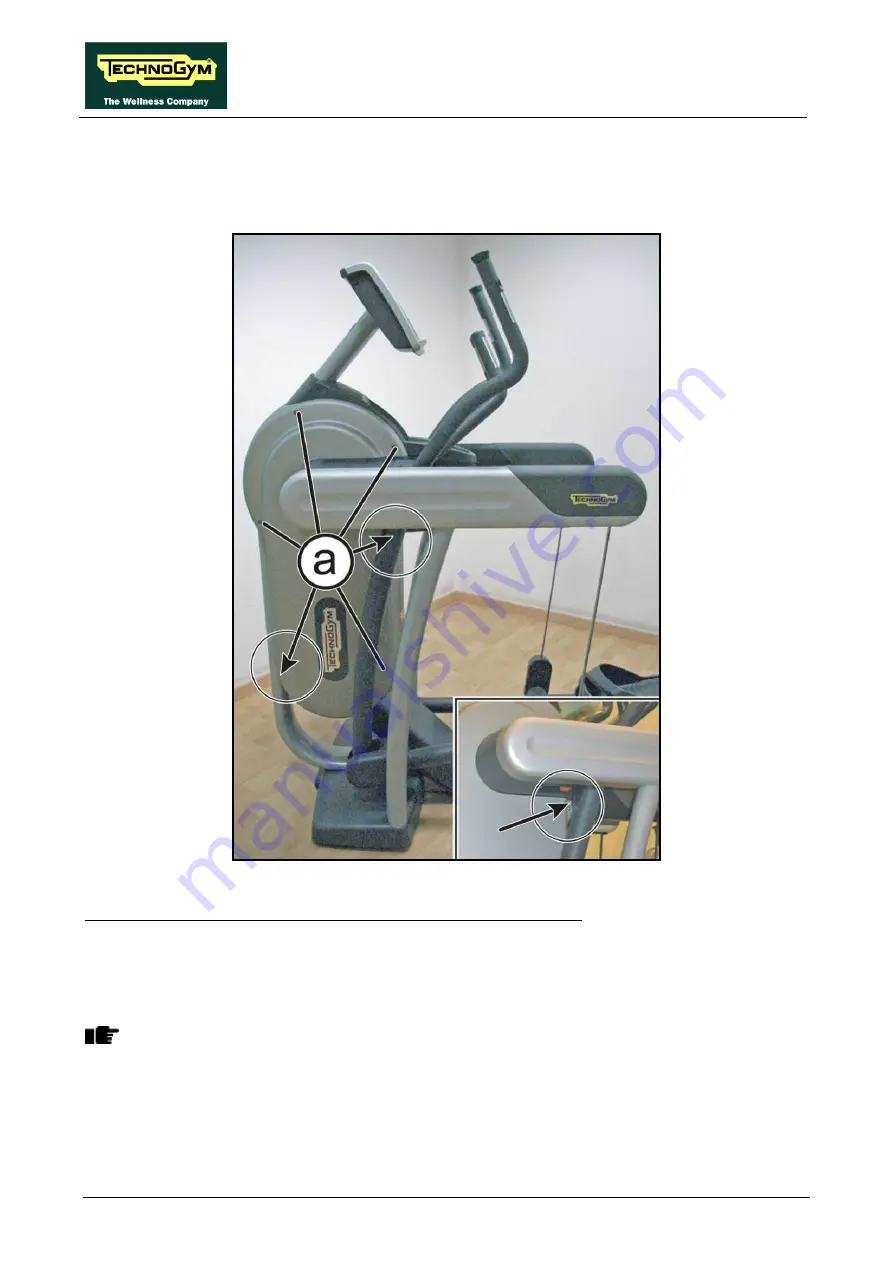

Figure 7.7-1

Turn off the machine and unplug the mains lead from the wall outlet.

1.

Using a 4mm hexagonal wrench, back off the six screws

(a),

remembering to replace the shorter

screws as indicated by the arrows in the figure.

Move the levers during removal of the guards, in order to find the best position for

disassembly.

To reassemble the centre guard,

carry out the above steps in reverse order.

Summary of Contents for Vario Excite + 500

Page 1: ...V VA AR RI IO O E X C I T E REV 4 2...

Page 2: ......

Page 4: ......

Page 10: ...VARIO Excite Service maintenance manual rev 4 2 Page vi Page intentionally left blank...

Page 58: ...VARIO Excite Service maintenance manual rev 4 2 Page 5 6 Page intentionally left blank...

Page 170: ...VARIO Excite Service maintenance manual rev 4 2 Page 7 70 Page intentionally left blank...

Page 206: ...VARIO Excite Service maintenance manual rev 4 2 Page 9 26 Page intentionally left blank...

Page 208: ...VARIO Excite Service maintenance manual rev 4 2 Page 10 2 Page intentionally left blank...

Page 219: ......