TD20 Series VFD

Fault Tracking

-85-

6 Fault Tracking

6.1 Maintenance intervals

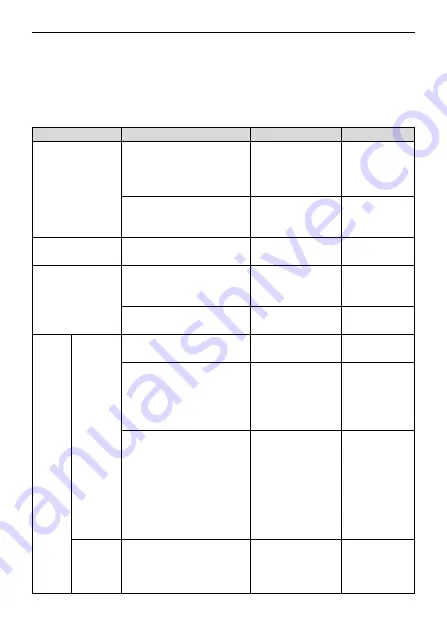

If installed in an appropriate environment, the VFD requires very little maintenance. The table lists the

routine maintenance intervals recommended by TECHTOP CANADA INC..

Checking part

Checking item

Checking method

Criterion

Ambient environment

Check the ambient temperature,

humidity and vibration and ensure

there is no dust, gas, oil fog and

water drop.

Visual examination

and instrument

test

Conforming to the

manual

Ensure there are no tools or other

foreign or dangerous objects

Visual examination

There are no tools

or dangerous

objects.

Voltage

Ensure the main circuit and

control circuit are normal.

Measurement by

millimeter

Conforming to the

manual

Keypad

Ensure the display is clear

enough

Visual examination

The characters

are displayed

normally.

Ensure the characters are

displayed totally

Visual examination

Conforming to the

manual

Main

circuit

For public

use

Ensure the screws are tightened

scurrility

Tighten up

NA

Ensure there is no distortion,

crackles, damage or

color-changing caused by

overheating and aging to the

machine and insulator.

Visual examination

NA

Ensure there is no dust and

dirtiness

Visual examination

NA

Note:

if the color

of the copper

blocks change, it

does not mean

that there is

something wrong

with the features.

The lead of

the

conductors

Ensure that there is no distortion

or color-changing of the

conductors caused by

overheating.

Visual examination

NA

Summary of Contents for TD20 Series

Page 1: ......

Page 129: ...TD20 Series VFD Appendix C Peripheral Options and Parts 127 PB External brake resistor TD20...

Page 131: ......