www.tecnaonline.com - info@tecnaonline.com

E N G L I S H

DANGER OF MATERIAL DAMAGE AND PERSONAL INJURIES!

The safety instructions in chapter “2 SAFETY” on page 7 must be followed.

»

Always use the necessary personal protective equipment, safety shoes, protective gloves, etc.!

»

The support frame must be stopped before working on the hydraulic breaker if the hydraulic

breaker is still attached to the jib.

»

Safeguard from an inadvertent re-start of the support frame (take out the key) and attach a

corresponding warning sign. Depressurise the hydraulic system for the hydraulic breaker; see the

operating manual of the support frame or the hydraulic system.

DANGER OF DAMAGE!

Incorrect filling quantity and/or unsuitable lubricant (tool paste) causes damage to the hydraulic

breaker!

The hydraulic system can be depressurised with the help of the circuit diagram, see the operating

manual of the support frame or the hydraulic system.

The inspection and maintenance conducted must be documented completely,

see section "14.2

PROOF OF MAINTENANCE" on page 44.

10

MAINTENANCE (DIN EN 31051)

PAR

DESCRIPTION

10.2

INSPECTION AND MAINTENANCE

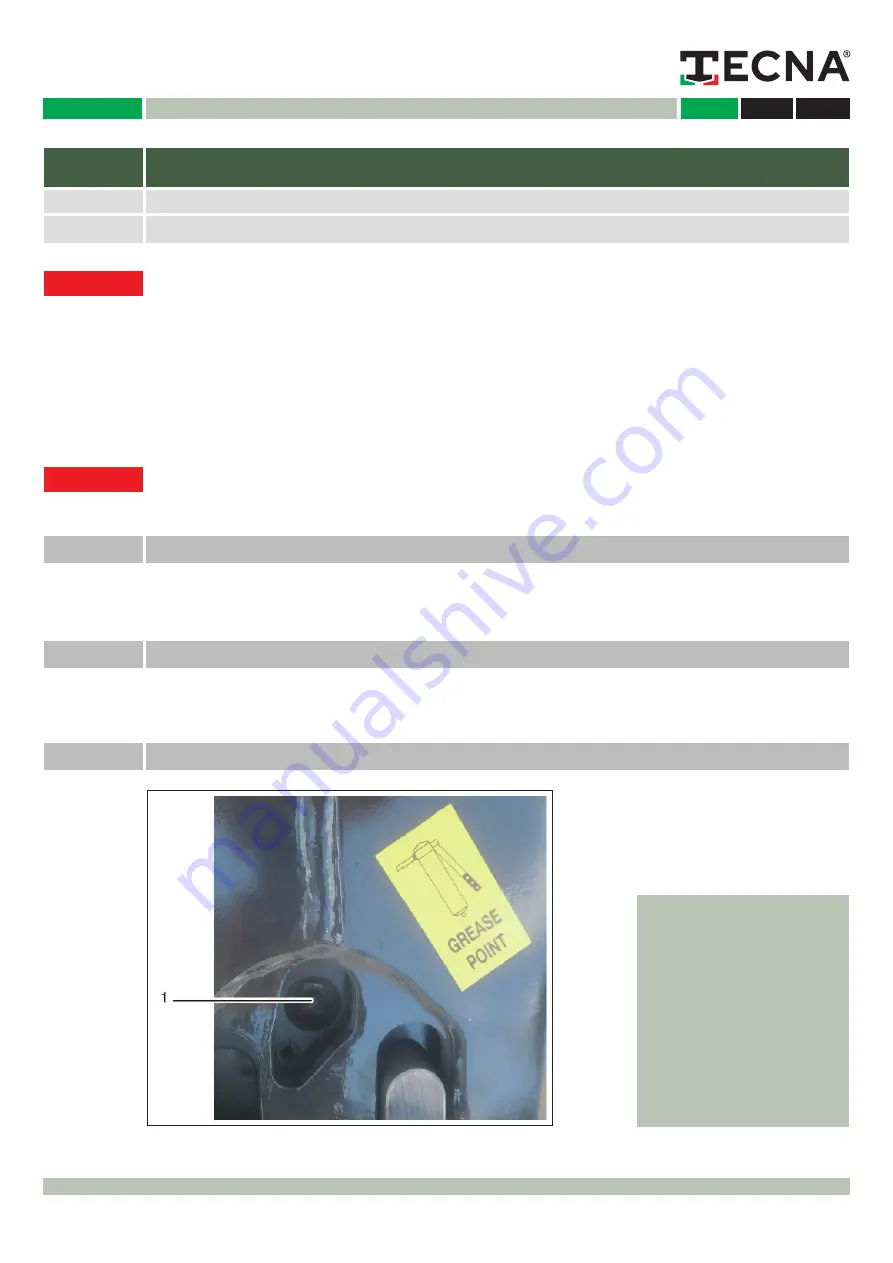

FIGURE 20: Lubrication point - (1) Lubricating nipple

10.2.1

ESTABLISHING PRESSURE RELIEF ON THE HYDRAULIC SYSTEM

10.2.2

LOG

10.2.3

INFORMATION REGARDING THE MAINTENANCE AND INSPECTION BODY

A sample design has

been shown in the

following figure. The

delivered hydraulic

breaker can thus

deviate from the

figure.

DANGER

DANGER

OPERATING MANUAL

-

H

ydraulic

breakers

T

series

34

/44

REV

0.0

MAINTENANCE (DIN EN 31051)

10