TE70 IR-HEATER

PAGE 17

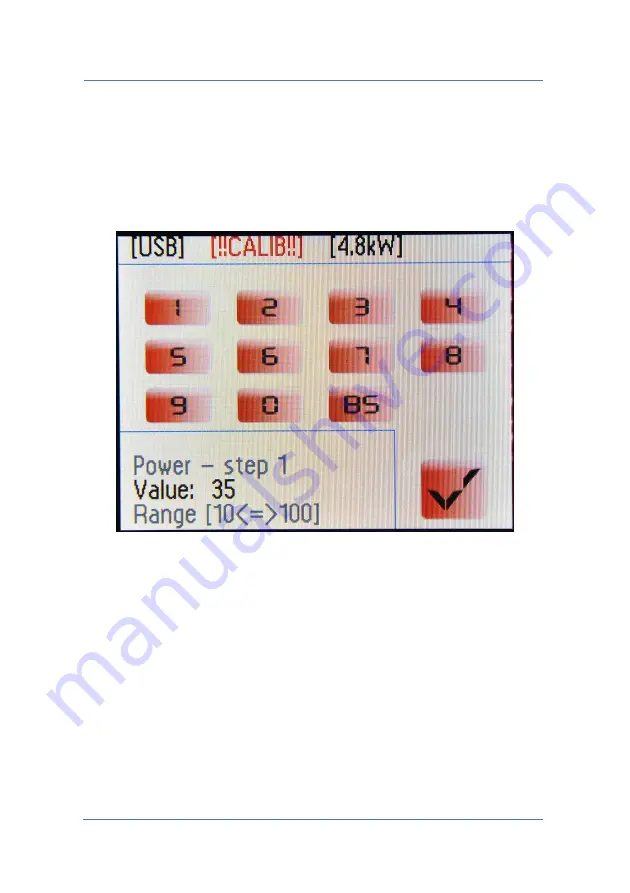

5.3 POWER SETTING

When you press the indication of the power to be delivered, a numeric

keypad will appear with which to set the power that must be delivered

by the heating tool during the profile's current step.

We recommend using high power values when working on matt

surfaces or when you want the piece to heat quickly. A lower power

value is advisable in the case of glossy surfaces or when you want a more

uniform distribution of the heat delivered within the material to be

heated.