22

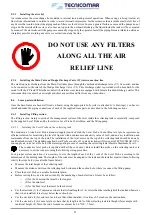

8.5.5

Installing the air relief

Air intake assure the air exchange from outside to internal tank, during normal operations. When sewage is being treated, air

flows from internal tank to outside in order to avoid internal overpressure; for these reasons the air intake must be left free of

any device that could obstruct the piping such as filters or other devices. In case a general failure occurs and the pumps do not

stop, and the motorized three way valve does not open to the outboard discharge, the liquid inside the tank will be evacuated

by means of the air intake until the pumps are manually stopped by the operator. Install the piping from air intake to outside as

straight as possible avoiding any curves or restrictions along the line.

DO NOT USE ANY FILTERS

ALONG ALL THE AIR

RELIEF LINE

8.5.6

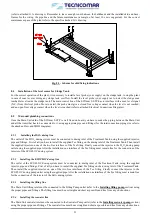

Installing the Main Unit and Sludge Discharge Valve (V2) interconnection line

The clarified water discharge from the Main Unit takes place through the motorized discharge valve (V1) free outlet; and has

to be connected to the inlet of the Sludge Discharge Valve (V2). This discharge outlet is provided with a hose barb for the

model with the PP tank. While the models with stainless steel tank are equipped with female threaded discharge outlet. This

interconnection line must be as straight and short as possible and free from any obstructions.

8.6

Loose parts installation

Once the base-frame are been well fixed on board, using the appropriate bolts (refer to attached G.A. drawings), you have to

install and make the piping connections of each of the supplied loose parts, as described in the following sections.

8.6.1

Installing Filling section

The filling section mainly consists of the management system of the level inside the collecting tank is essentially, composed

by the supplied Level Probe and by the relative Level Probe Control Box; and the filling pump.

8.6.1.1

Installing the Level Probe on the collecting tank

The conductive 3-rods Level Probe (standard supply) matched with the Level Probe Control Box level probe represents an

efficient solution for monitoring the level of liquids with a minimum conductivity value of 1mS, and an easy installation and

maintenance from the top of the tank. The installation of the level sensor on the top of the collecting tank should be done by

qualified technicians. The standard supplied Level Probe consists of 3 coated electrodes (if it is require TECNICOMAR S.P.A.

con supply a 4-rods Level Probe for the alarm signaling in case of reaching the collecting tank Absolute Maximum Level).

The conductive level probe is supplied with all the rods uncut. Before install the probe on the collecting tank, it is

necessary to cut the rods according the following sizing procedure.

For a proper system operation it is necessary to size the length of each of the 3 rods of the Level Probe, according to the

dimensions of the holding tank. The lengths of the rods must be adapted to the tank and the installer must cut them, following

strictly the steps below (see also the figure below):

•

Measure the total height of the collecting tank;

•

Measure the distance between the collecting tank bottom and the suction hole, where to connect the filling pump.

•

Place the Level Probe on a stable horizontal plain;

•

Before cutting the rods (electrodes) identify the numbering of each electrode. It must be as follow:

o

(1) for the Common, that must be the longest,

o

(2) for the min level,

o

(3) for the Max level that must be the shortest;

•

Cut the electrode (1) for Common as to have that its final length is 3-4 cm less than the total height of the tank and however

that, when installed, it is always below the suction hole;

•

Cut the electrode (2) for min level as to have that, when installed, it is always 2-5cm above the suction hole;

•

Cut the electrode (3) for max level as to have that its length is 60% of the collecting tank total height (for example with

tank total height of 120cm the rod 3 for max level must be: 0.6*120 = 72cm).