25

The pump should be bolted to a firm, flat base in a dry, well ventilated area. If mounted outside, it is recommended that the

motor be protected from the elements with a well ventilated weather proof cover. If mounted near walls, it is recommended a

distance of at least 100mm between the suction grid of the cooling fan of the motor and the wall. The pump should be accessible

for inspection and repair.

At first start up you can check it manually following the manual procedure (refer to the Manual mode

section

)

.

BEFORE OPERATING ON THE PUMP, MAKE SURE THAT PUMP IS POWERED OFF AND THAT IT CANNOT

BE ACCIDENTALLY POWERED ON.

Fill the pump casing with liquid, connect the inlet and the outlet of the pump to the respective piping. The pump must rotate

anti-clockwise. Check that the direction of rotation is as shown by the arrow on the pump casing, otherwise disconnect electrical

power and reverse the connections of two phases.

ATTENTION

: Never run the pump dry. Start the pump only after filling completely with liquid. FILL THE PUMP

WITH LIQUID BEFORE STARTING. NEVER LET THE PUMP RUN DRY.

We recommend to adopt the following precautions during the installation and the operation of the pump:

For some installation configurations, the stop of the pump may cause the complete emptying of the pump case. In this

case, it is necessary to install a not return valve on the suction piping.

Make sure that the pump never run dry.

When a foot valve filter is installed on the pump suction side, check periodically its efficiency and cleanness.

Check that the rotor never blocks, this may cause serious damage to the motor. If this happens clean well the pump case

and the rotor. If it is necessary replace the rotor.

WARNING:

The installation and maintenance operations must be performed by qualified personnel, using suitable

means and the appropriate individual protections such us gloves.

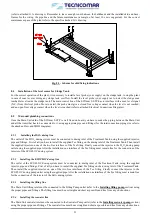

8.6.1.2.1

Installation of the suction pipe of the filling pump

When the ECOmar S treatment plant has to treat water with high concentration of sewage, it is recommended to install the

suction pipe of the filling pump in the collecting tank at a distance of 20-30 cm from the tank bottom, in order to perverse

instruments and mechanical parts of the plant from any damages. Moreover, in the case of sewage with high concentration the

sediment should not reach the suction pipe and therefore the tank should be periodically monitored by the board crew to prevent

this to happen.

8.6.2

Installing sea water pump

The sea water pump should be fixed on a stable horizontal plain, below the sea water line so that to avoid priming failures,

using the proper bolts (refer to attached G.A. Drawings). Remember that this pump is not self-priming and that at first start up

it is necessary to check the priming. In case of problem we suggest to run the pump manually following the manual procedure

described in the

Manual mode

section. This pump must be installed whit the rear axis horizontal and feet downwards. For

safety reasons avoid the position with the motor under the pump. Place the pump as close as possible to the suction source (on

board seacock), and make sure that the surrounding is adequately ventilated.

The adduction pipeline has to be preceded by a safety valve (not supplied). Remember also that the anti-siphon valve has to be

fitted above the water line, on the delivery side.

Provide a diameter assuring e liquid flow not greater than 1.5 m/s for suction and 3 m/s for delivery. The pipe diameters must

never be smaller than the pump connections. Secure all the pipes to rests and connect them so that they are not under stress and

do not transmit vibration or flexing strain to the pump.

We recommend to adopt the following precautions during the installation of the pump suction piping:

The suction pipe must be perfectly airtight and be led upwards in order to avoid air pockets.

For pump working in suction lift operation condition, fit a foot valve with strainer which must always remain immersed.

For pump working in suction from a storage tank condition, fit a check valve.

For pump working with a positive suction head, fit a gate valve.

When the pump is located above the water level (suction lift operation), fill the suction pipe and the pump through the

priming hole, on the pump front side.

When the liquid level on the suction side is above the pump (inflow positive suction head), fill the pump by opening the

suction gate valve slowly and completely, keeping the delivery gate valve open to release the air.

ATTENTION:

never run the pump dry- not even for a short trial run. Start the pump after filling completely with

liquid.

We recommend to adopt the following precautions during the installation of the pump delivery piping:

Fit a gate valve into the delivery pipe to adjust delivery, head, and absorbed power.

Install a pressure gauge to check the pump operation.

With a geodetic head outlet over 15 meter fit a check valve between the pump and the gate valve in order to protect the

pump from water hammering.