26

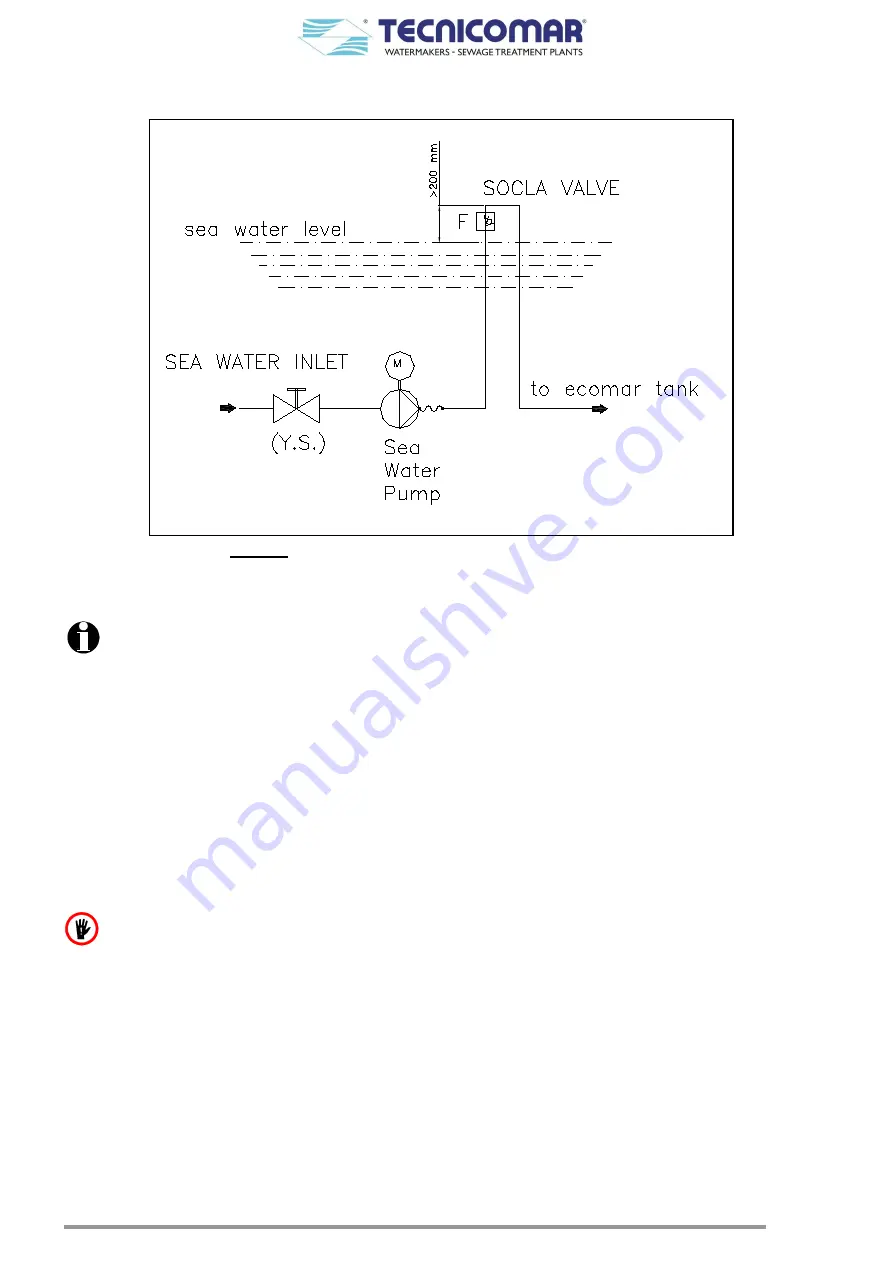

When the liquid level on the suction side is above the pump (inflow positive suction head), install the sea water anti

siphon valve set, on the delivery line 20-30 cm above the water line (refer to figure below).

Fig. 8.6.2 - Connection scheme for Sea Water anti-siphon valve set

When the pump is supplied with a three-phase motor, check that the direction of rotation is as shown by the arrow on the pump

casing, otherwise disconnect electrical power and reverse the connections of two phases.

Check that the pump works within its field of performance, and that the absorbed current shown on the name-plate is

not exceeded.

8.6.3

Installing H

2

O

2

dosing system

The base frame of the H

2

O

2

Dosing System must be fixed on a stable horizontal plane, using the proper bolts (refer to attached

G.A. Drawings). After this, check that the liquid inside the tank is enough to ensure the correct operation of the system. This

disinfecting agent must be efficient and well stored (refer to attached H

2

O

2

Safety Data Sheet). Verify that the injector is

correctly installed on the treatment tank and connected to the dosing pump. If all the electric and hydraulic connections are

made (refer to attached Flow and P&ID Diagrams and to attached Electric Connections Diagrams), it is possible to start the

dosing pump. Be sure that pump fill the pipe. If the pipe is long and completely empty this should require some minutes.

8.6.3.1

Transfer of H

2

O

2

solution

Before running the dosing system, it necessary to fill the dosing system tank with the H

2

O

2

solution.

Proceed with caution using gloves and protecting glasses in order to avoid direct contact with the corrosive chemical

(refer to H

2

O

2

Safety Data Sheet).

To fill the tank, perform the following procedure:

•

Prepare the supplied hand operated diaphragm pump.

•

Unscrew the caps both of the system’s disinfecting liquid tank and of the can with fresh disinfecting liquid.

•

Close the drain cock of the diaphragm pump.

•

Submerge the other end of the pump in the can containing disinfectant liquid to be transferred.

•

Pump until the circuit of the diaphragm pump will be filled with disinfectant liquid (refer to the figures below).

•

Place the cock on the filling hole of the system’s disinfecting liquid tank and open the cock. It is recommended to transfer

about half of the disinfecting liquid contained in the can.

•

Once the transfer is completed, close the cock, lift it vertically and open it again to empty the drainage pump (see figure

below).

3~