59

14

MAINTENANCE INSTRUCTIONS

The ECOmar S STP requires some ordinary and extraordinary maintenance.

NOTE:

This section concern only the standard supply configuration of the ECOmar S STP for the optional items

maintenance, refer to the specific item manual.

Some components of the ECOmar S STP, such us the

bag cartridge

of the

safe filter

of the

U.V Sterilizing System

, need to be

periodically cleaned and replaced (

ordinary maintenance

). Other safety components, such as the

3-way solenoid valves

and the

seawater pump

, need no periodic maintenance but must be checked periodically and maintained only if necessary

(

extraordinary maintenance

). Moreover some electrical devices, such as the

Dosing Pumps,

may need some

calibration

.

Periodically perform the following maintenance instructions to ensure a safe use and longer life to the ECOmar S plant.

14.1

Ordinary Maintenance

The components of the ECOmar S STP, that require periodic ordinary maintenance, are the H

2

O

2

Dosing System, the

ECOFLOC Dosing System, the Multimedia Filter Station and the U.V. Sterilizing System. However it is recommended to daily

perform a general check and inspection of the whole plant.

14.1.1

H2O2 Dosing system

While the ECOmar S STP is operating periodically check that the dosing pump is correctly running; if it is not running verify

the cause of the problem (refer to the

Extraordinary Maintenance

section), fix it and restart the pump.

ATTENTION: If the chemical solution inside the tank ends up, the dosing pump continues to run and the

ECOmar S STP will continue to run without treating the sewage. To restore the plant correct functioning fill

the tank. The pump will automatically re-start to inject the chemical solution inside the treatment tank.

Check daily the level of the H

2

O

2

solution inside the tank; and refill it (refer to the

Transfer of H

2

O

2

solution

section) before

the liquid inside the tank ends up. The periodic check of tank chemicals level is essential to avoid the plant operating without

the addition of H

2

O

2

solution; because it will bring to a sewage treatment failure. Sewage treatment is not possible without the

addition of any of the two chemical solutions.

The H

2

O

2

solution consumption depends on the system running period, on the ECOmar S supplied model, on the relative

dosing pump flow regulation and on the setting value of the Dosing Timer parameter.

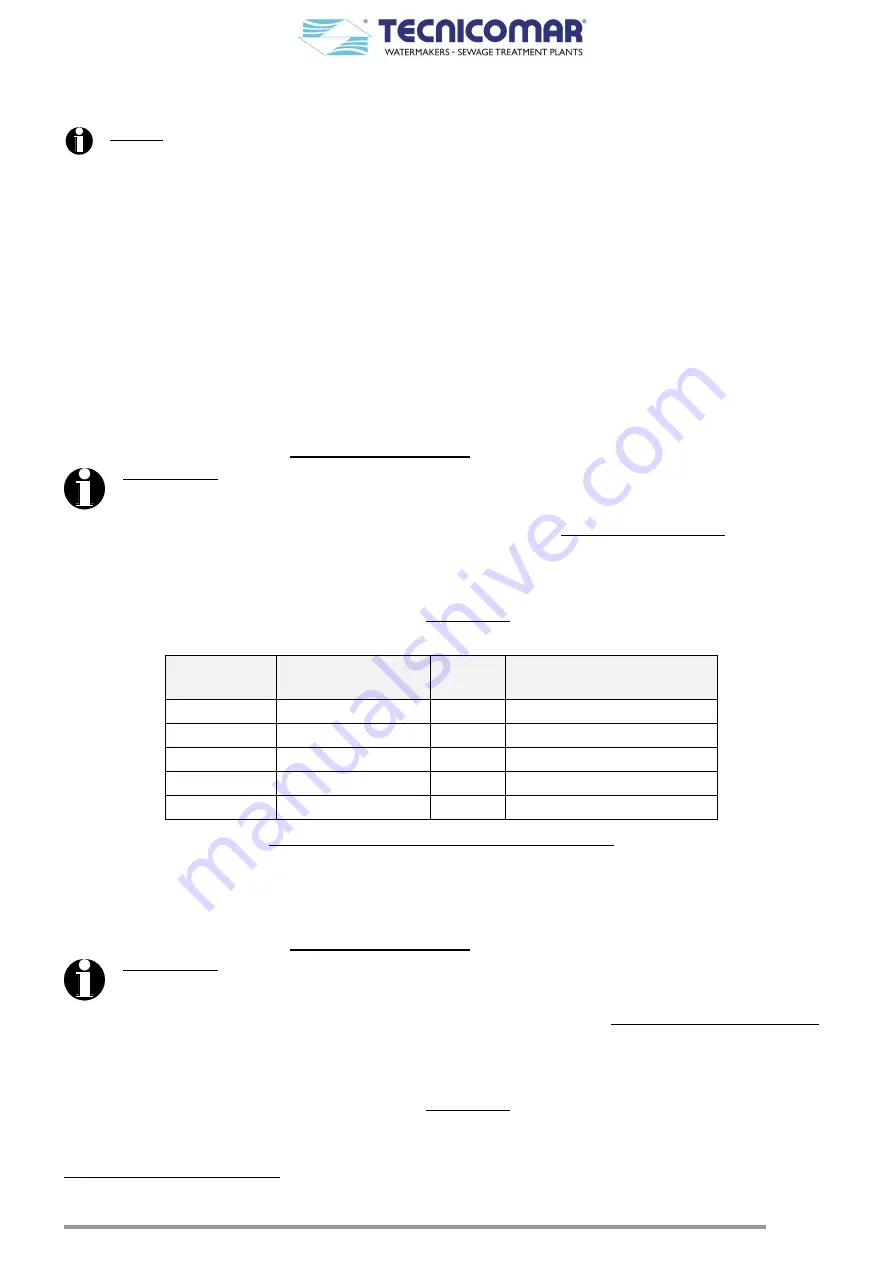

Here below a table with the indicative plant consumption of H

2

O

2

solution:

Model

Valve Regulation

(%)

Timer

*

(sec.)

Indicative consumption

(liters/month)

ECOmar 20 S

40 %

26

20÷75

ECOmar 32 S

40 %

40

30÷120

ECOmar 45 S

40 %

50

40÷165

ECOmar 70 S

54 %

60

60÷260

ECOmar 145 S

54 %

137

115÷530

Table 14.1.1 – H2O2 dosing system consumption table

14.1.2

ECOFLOC Dosing system

While the ECOmar S STP is operating periodically check that the dosing pump is correctly running; if it is not running verify

the cause of the problem (refer to the

Extraordinary Maintenance

section), fix it and restart the pump.

ATTENTION: If the chemical solution inside the tank ends up, the dosing pump continues to run and the

ECOmar S STP will continue to run without treating the sewage. To restore the plant correct functioning fill

the tank. The pump will automatically re-start to inject the chemical solution inside the treatment tank.

Check daily the level of the ECOFLOC solution inside the tank; and refill it (refer to the

Transfer of ECOFLOC solution

section) before the liquid reach the minimum level of the tank. The periodic check of tank chemicals level is essential to avoid

the plant operating without the addition of ECOFLOC solution; because it will bring to a sewage treatment failure. Sewage

treatment is not possible without the addition of any of the two chemical solutions.

The H

2

O

2

solution consumption depends on the system running period, on the ECOmar S supplied model, on the relative

dosing pump flow regulation and on the setting value of the Dosing Timer parameter.

Here below a table with the indicative plant consumption of ECOFLOC solution 20%:

*

Refer to attached Test Report

†

Max value refer to plant continuous functioning (24h/24h). Min value refer to plant operating 160 hours a month.