66

14.4

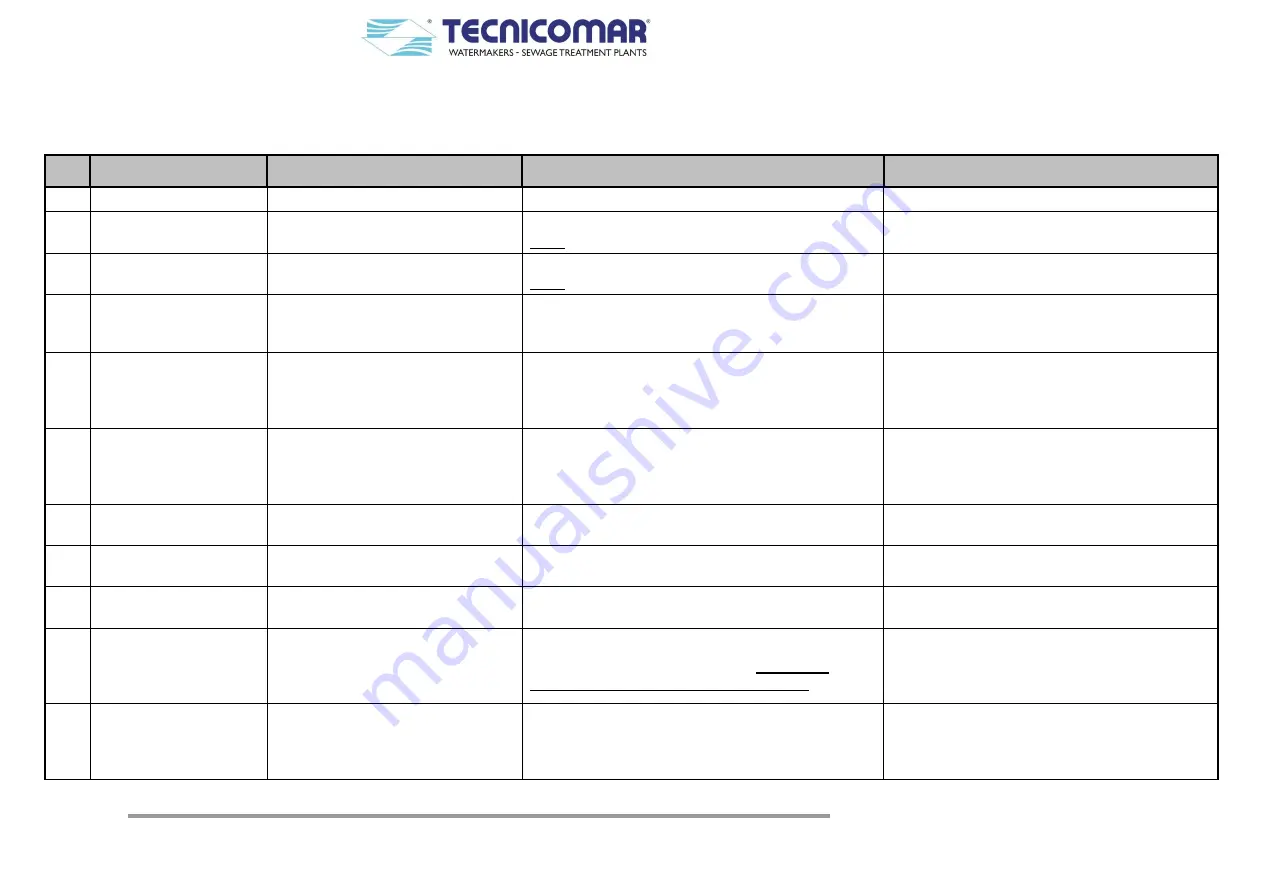

MAINTENANCE PLAN FOR SEWAGE TREATMENT PLANT ECOMAR S

P/N SCHEDULE

COMPONENT

MAINTENANCE ROUTINE

WARNINGS IF NEGLECTED

1

Every day

The whole ECOmar S plant.

System general check and inspection.

Undetected malfunctioning could occur.

2

Every day

Hydrogen Peroxide tank;

ECOFLOC tank.

Check the level of the chemical products.

Note:

The level must never be below 10 cm.

Undetected plant malfunctioning, due to H

2

O

2

,

ECOFLOC or both solutions missing, could occur.

3

Every month /

On condition

Hydrogen Peroxide tank;

ECOFLOC tank.

Add chemical products if necessary.

Note:

The level must never be below 10 cm.

Sewage treatment is NOT possible without chemical

products.

4

Every month

Air intake

• Check if air is released properly.

• Check that air intake is not obstructed.

• Check if exhaust pipe is straight in vertical dimension.

Burst of the treatment tank.

5

Every 1-2 months /

On condition

Level probe(s)

(inside ECOmar S treatment tank)

Uninstall and clean the floating probes, installed on

treatment tank.

Dirty probe gives no signal, so in case of no signal

to the electronic card then the treatment tank might

get overfull and liquids could escape from the air

outlet.

6

Every 2 months

Dosing pumps

Inspection of the suction ball check valve and

discharge ball check valve.

In case of obstruction clean the valves with fresh water.

In case of corrosion replace the valves.

Dosing pumps stop working and consequently the

sewage does not get properly treated.

7

Every 3 months /

On condition

Stainless Steel and PVC fittings

Inspection.

In case of leakage tighten properly with dedicated tool.

Leakages.

8

Every 3 months

Supplied Level Probes

(inside collecting tank)

Clean the contacts with abrasive paper.

Probe may not work properly due to oxidation.

Misleading or missing level signals.

9

Every 3 months /

On condition

Sterilizer of U.V. Sterilizing System

Empty the system radiation chamber, remove the quartz

tube(s) and clean or replace quartz tube(s), if necessary.

Undetected plant malfunctioning, due to U.V.

Sterilizing system out of service, could occur.

10

Every 3-6 months

3-Way Discharge Valve (V1)

(controlled by motorized actuator);

3-Way Sludge Discharge Valve (V2)

(controlled by motorized actuator).

Check the correct activation / de-activation of 3-Way

valve, without any blockage (refer to

COMMON

PROBLEMS AND TROUBLESHOOTING

section).

Correct system operation impossible in case of

locked valves. Motorized actuators burn due to dirty

gear.

11

Every 3-6 months

Filling pump(s)

Macerating pump

Seawater pump

Discharge pump

*

Check and, if needed, replace:

- seal kits

- impellers

System does not work effectively.