7

6

SYSTEM DESCRIPTION

The ECOmar S STP can be supplied with two different configuration: 1 Tank Control or 2 Tanks Control.

The main differences between the two configurations are the number of the supplied filling pumps (1 or 2); the number of the

supplied anti-syphon valve set; the number of the supplied level probes; the number of the supplied level probe control boxes;

the dosing systems arrangement and the main control box arrangement.

The diagrams below show a functional installation scheme of the plant with its main components for both configurations.

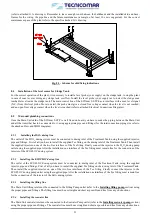

Fig. 6-1 - Functional installation scheme – 1 Tank Control - (see also annexed drawing)

Fig. 6-2 - Functional installation scheme – 2 Tanks Control - (see also annexed drawing)

As shown in the diagrams above, the system is composed by:

1.

A

Main Unit Skid

made by:

1.1.

A tank (

Treatment Tank

) made of PP (polypropylene) or SS (stainless steel)

, where the sewage water is treated;

1.2.

A pump (

Macerator

or

Macerating Pump

) to treat and discharge the treated water;

1.3.

A motorized

Discharge Valve

(

V1

) to divert the treated water to the

sludge discharge valve

(V2)

inlet or back to the

treatment tank;

1.4.

Level probes

, installed on the treatment tank, for the tank level monitoring;

1.5.

A pressure sensor (

Pressure Switch

)

to protect the treatment tank from overpressure;

1.6.

A PCB control panel (

Main Control Box

) with motor protections, contactors, microprocessor, touch pad and liquid

crystal back-lighted display.

*

For the ECOmar 70 S and 145 S; the treatment tank is available only in SS (stainless steel).

†

Nr.1

Multi-point Ball Level Switch

for ECOmar 20 S – 32 S – 45 S – 70 S – 145 S.

‡

Only for the STP supplied with the treatment tank in PP (polypropylene).