10

Prior to installation

❑

Flat ducts

must have an internal cross-

section that equates to that of round

pipes.

There should be no sharp bends.

l

100 mm approx.

1

78 cm

2

l

125 mm approx. 113 cm

2

❑

If pipes have different diameters:

Insert sealing strip.

❑

For exhaust-air mode,

ensure that

there is an adequate supply of fresh air.

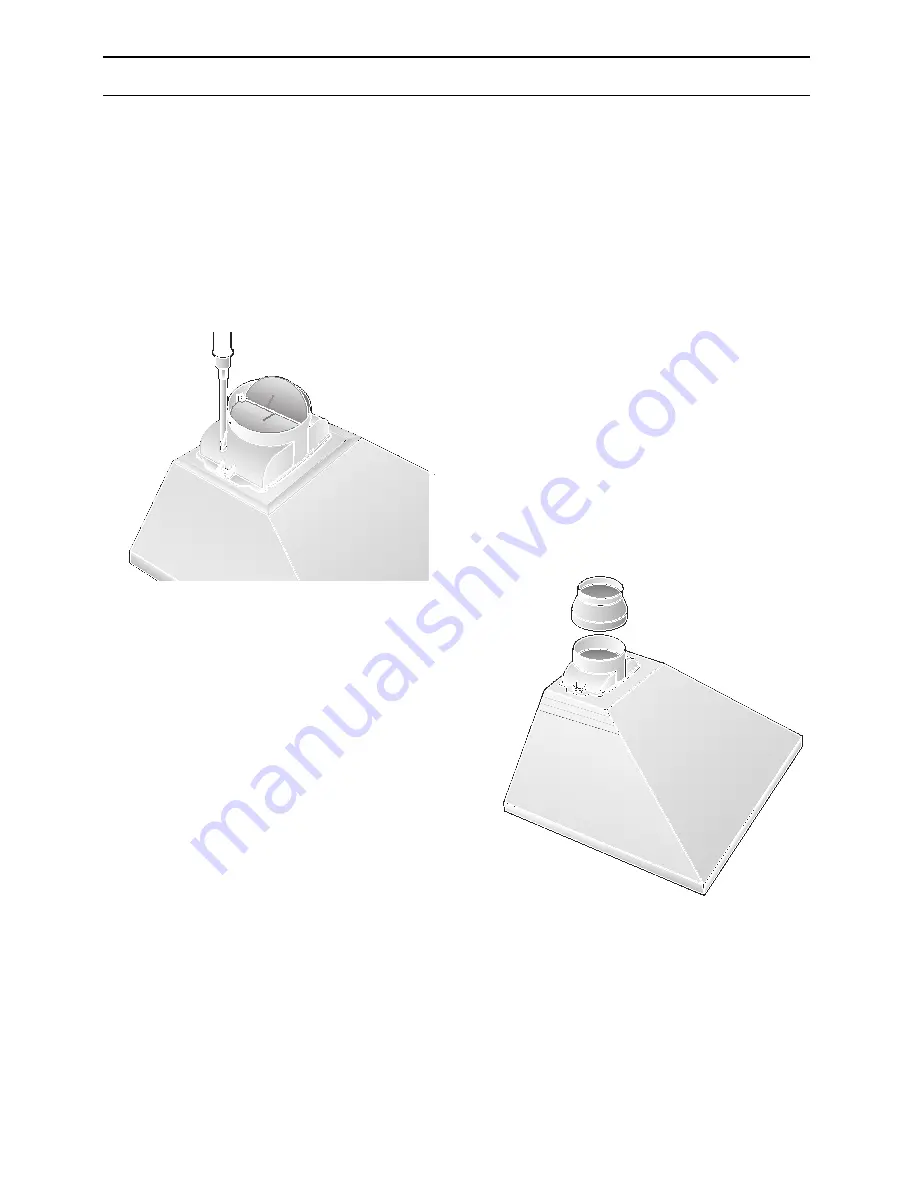

Connecting a

l

125 mm exhaust-air

pipe:

❑

Mount the pipe directly onto the air

outlet on the hood.

Connecting a

l

100 mm exhaust-air

pipe:

❑

Attach the reducing connector

(enclosed or available from specialist

retailer) to the air pipe and then attach

to the exhaust-air duct.

For operating in exhaust-air mode,

a

one-way flap should be mounted inside the

extractor hood unless there is already one

fitted in the outlet duct or wall ventilation

box.

If no one-way flap was enclosed with the

hood, it can be obtained from a specialist

retailer.

Installing the one-way flap:

❑

Snap the one-way flap into the air pipe.

The two lightly sprung flaps must be

able to move upwards.

If the exhaust air is going to be

discharged into the open,

a telescopic

wall box should be fitted into the outside

wall.

For optimum extractor hood efficiency:

❑

Short, smooth air exhaust pipe.

❑

As few bends in the pipe as possible.

❑

Diameter of pipe to be as large as

possible and no tight bends in pipe.

If long, rough exhaust-air pipes,

many pipe bends or smaller pipe

diameters are used, the air extraction

rate will no longer be at an optimum

level and there will be an increase in

noise.

❑

Round pipes:

We recommend

Internal diameter:

125 mm

(at least

100 mm).