INSTALLATION AND SETTING INSTRUCTIONS

9

41.

0

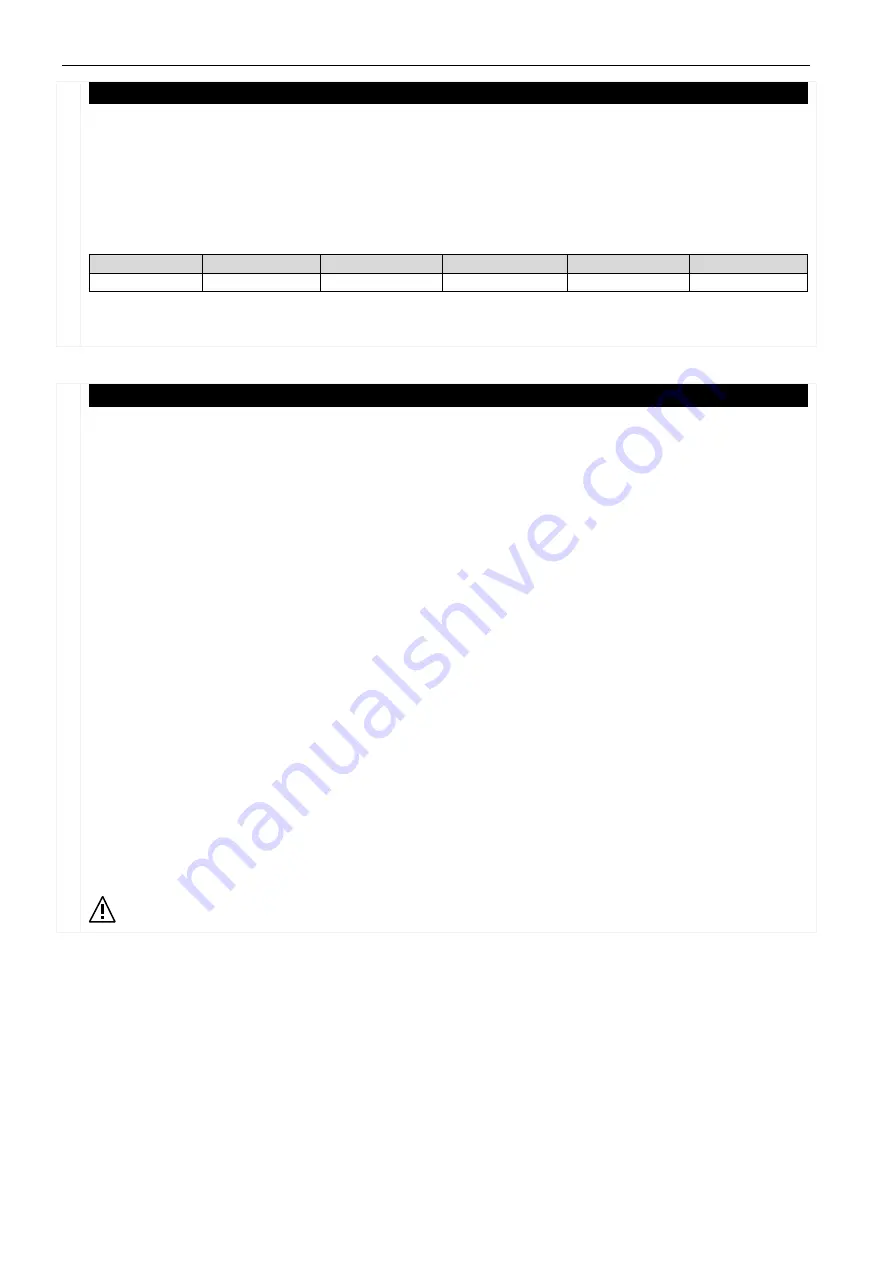

FAN MOTOR CONTROL

In the electric panel there is an outlet for fan motor (MV) control.

If the applied electric load is lower than that shown in the table set forth hereunder, such outlet can be

used directly; otherwise it can be used to operate a relay and/or contactor.

Fan motor power - table:

TYPE

1-2-3-7-8-9

4-10

5-11

6-12

Power

kW

0,5

0,75

1,1

1,5

A paper version of the wiring diagram is included in the appliance. It is an integral part of these instructions

and we recommend keeping it carefully.

CHECKS

In order to ensure that the machine works properly, some basic parameters should be checked. Activate the

machine and:

•

Check that the ventilation unit starts after max. 30 s from the burner activation.

While the warm air heater is normally working (after approx. 20 minutes of uninterrupted working), perform

the following operations:

•

Measure the air flow, as it is crucial to get an optimal room heating and furthermore is necessary in

order to adequately cool the heat exchanger. The absence of any kind of resistance on the air flow

generated by the fan is essential. Therefore, avoid any obstacles hindering air supply and return.

•

Check that there is no fuel leakage.

•

Check that the fuel flow is correct by reading the meter.

•

Check the combustion parameters.

•

Check that the installed safety devices do not operate anomalously.

•

On the remote control panel, lower the set-point to a value lower than the room temperature and

check that

only the burner

turns off and that the fan unit does not simultaneously stop.

•

Check that the fan works for 3 minutes after the burner has stopped, before stopping as well.

•

Check that the thermal gradient is equal to the one specified in the TECHNICAL DATA paragraph.

The thermal gradient is the difference between the air outlet and air inlet temperature. Since the air

outlet temperature is not constant through its outlet section, in order to get this value, several

temperature measurements have to be carried out (throughout its outlet sections) and then the

arithmetical mean has to be calculated.

•

Check that the air pressure gauge of the burner is correctly calibrated, so that it stops if the

comburent air is not enough - since this might cause a non hygienic combustion

All the checks above mentioned should be performed in all the arranged working

conditions (max and min).