I.T.S. Ital Trade Services PT 630 Operating Manual

10

10

10

10

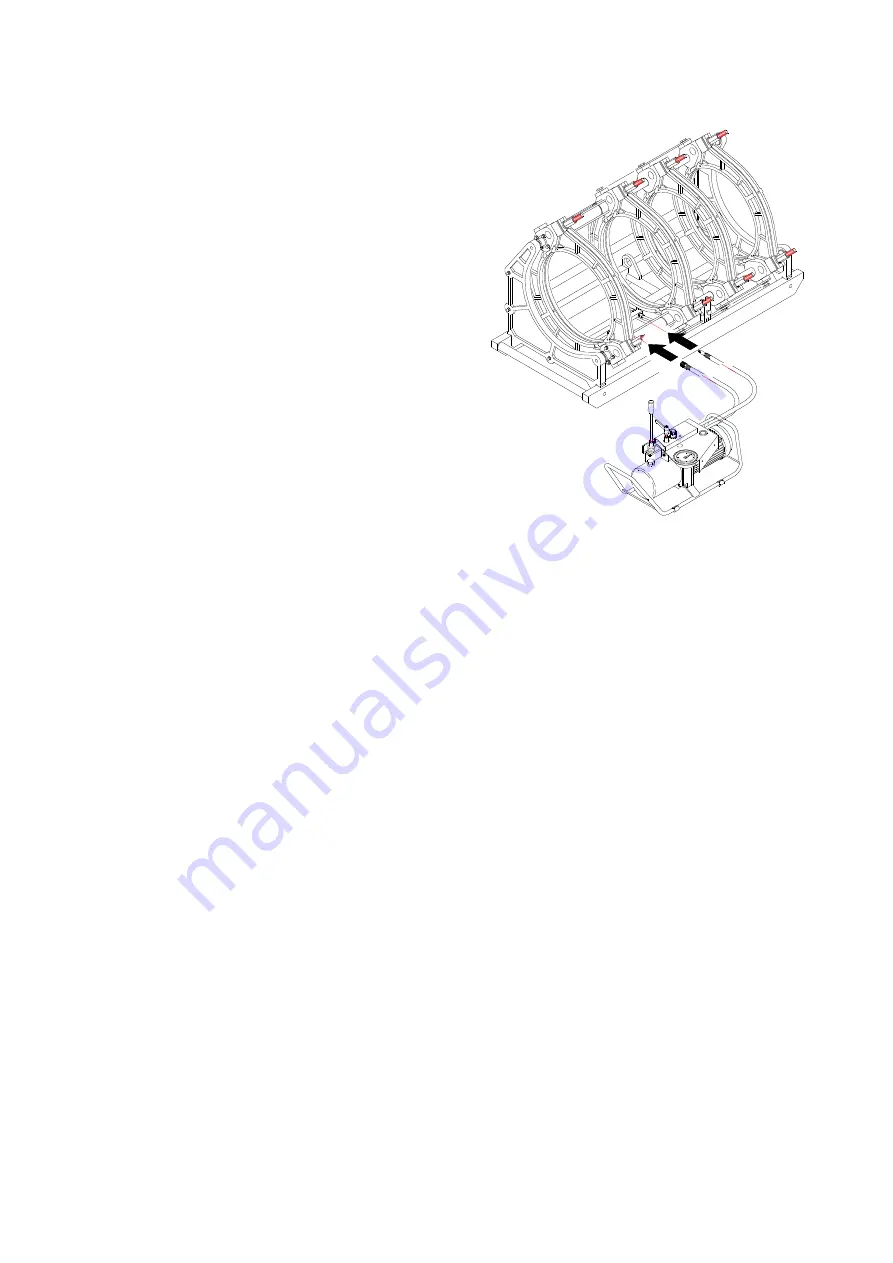

2.4.2 How to use the hydraulic unit

Operating Instructions

In order to make easy the learning we shall proceed to the description step by

step of all operations need in order to complete a welding according to the

following description:

Important !

Before begin the following operation be sure that:

- The lever

A

is fixed into the special housing

- Substitute the metal plug with the plastic black and red plug the

plastic plug is supplied with the machine into a plastic bag.

01.

Fit the two pipes to be weld ( see relative instructions )

02.

By turning the lever

E

anticlockwise bring the pressure to zero,

checking the pressure gauge

D

03.

Turn clockwise the lever

E

until closing ( please avoid using an

excessive strength )

04.

Bring the lever

A

into position

A3

05.

By turning clockwise the hand wheel

F

achieve the inertial pressure

value ( value of pressure need in order to allow the trolley moving )

note the value of inertial pressure read into the pressure gauge

D

,

then by still operating the hand wheel

F

, increase the inertial pressure

value by the welding theoretical pressure value as per attached table.

06.

Achieved the true welding pressure value ( inertial pressure plus

theoretical welding pressure ) bring the lever

A

into position

A2

.

07.

Fit the facing tool (see relative instructions )

08.

By acting on lever

E

anticlockwise achieve a pressure value of approx 5 bar more than the inertial pressure value checked and

then proceed to the facing tool operation (taking care that the engine's overloading).

09.

At the end of the facing operation bring the lever

A

into position

A3

and remove the facing tool.

10.

Fit the heating mirror taking care that the temperature of the surfaces is the one selected (see relative instructions)

11.

Bring the lever

A

into

A3

in order to have the bead formation as per attached table, this operation must be done with the true

welding pressure value.

12.

After bead formation act on lever

E

anticlockwise in order to bring the pressure to zero and proceed to the heating time as per

attached table.

13.

Elapsed the heating time at pressure zero bring the lever

A

into position

A2

and remove the heating mirror and immediately

bring the lever

A

into position

A3

and acting on lever

E

clockwise put in contact the two pipes until achieving the true welding

pressure value by checking the pressure gauge

D.

These operations must be done according to the time indicated into the

attached table.

14.

Bring the lever

A

into position

A1

and keep such situation for all the cooling time indicated into the attached table, taking care

that the pressure will not decrease too much, in case bring for a little while the lever

A

into position

A3

and put back into position

A1

15.

Elapsed the cooling time by acting on lever

E

anticlockwise bring the pressure to zero.

16.

Take away the pipes welded

WE STRONGLY SUGGEST TO TRY MANY TIMES AND GET FAMILIAR TO THE UNIT BEFORE CARRYING ON WITH COMPLETE WELDING.

A WRONG USE OF THE HYDRAULIC UNIT COULD COMPROMISE YOUR WELDINGS..

Click

Click

Summary of Contents for I.T.S. PT 630

Page 1: ...I T S by Tecnodue PT 630 Edition 1208 Operating Manual ...

Page 26: ...I T S Ital Trade Services PT 630 Operating Manual 26 26 26 26 9 4 Hydraulic plan ...

Page 29: ...I T S Ital Trade Services PT 630 Operating Manual 29 29 29 29 ...

Page 31: ...I T S Ital Trade Services PT 630 Operating Manual 31 31 31 31 ...

Page 33: ...I T S Ital Trade Services PT 630 Operating Manual 33 33 33 33 ...