I.T.S. Ital Trade Services PT 630 Operating Manual

22

22

22

22

7. Maintenance

7.1 Basic machine

It's strongly suggested to keep always the machine clean with particular care of the bolts and the cylinder's heads .

Keep attention while insert the electric facing tool and the PTFE coated heating mirror avoiding to damage the machine's slide bars.

7.2 Facing tool

It's strongly suggested to keep always clean the blades and wash the pulleys by using a detergent.

At regular intervals carry out a complete cleaning operation with a internal lubrication as well , as per following instructions:

- Remove the carter by enlighten the screws

- Take out the shavings might be present

- Enlighten the screws and remove the pulley and carry out the cleaning and the lubrication of the bearing .

7.3 Heating mirror

Please take care on handling the heating mirror in order to avoid damages to the PTFE coating.

Keep always clean the PTFE coated surfaces, cleaning must be done with surface still warm by using a soft cloth or paper, avoiding

abrasive materials in that might damage the PTFE coated surfaces. To achieve this operation you must wear protective gloves

At regular intervals we suggest you to:

- Clean the surfaces by a quick evaporation detergent (alcohol)

- Check the tightening of the screws and the cable and plug condition

-

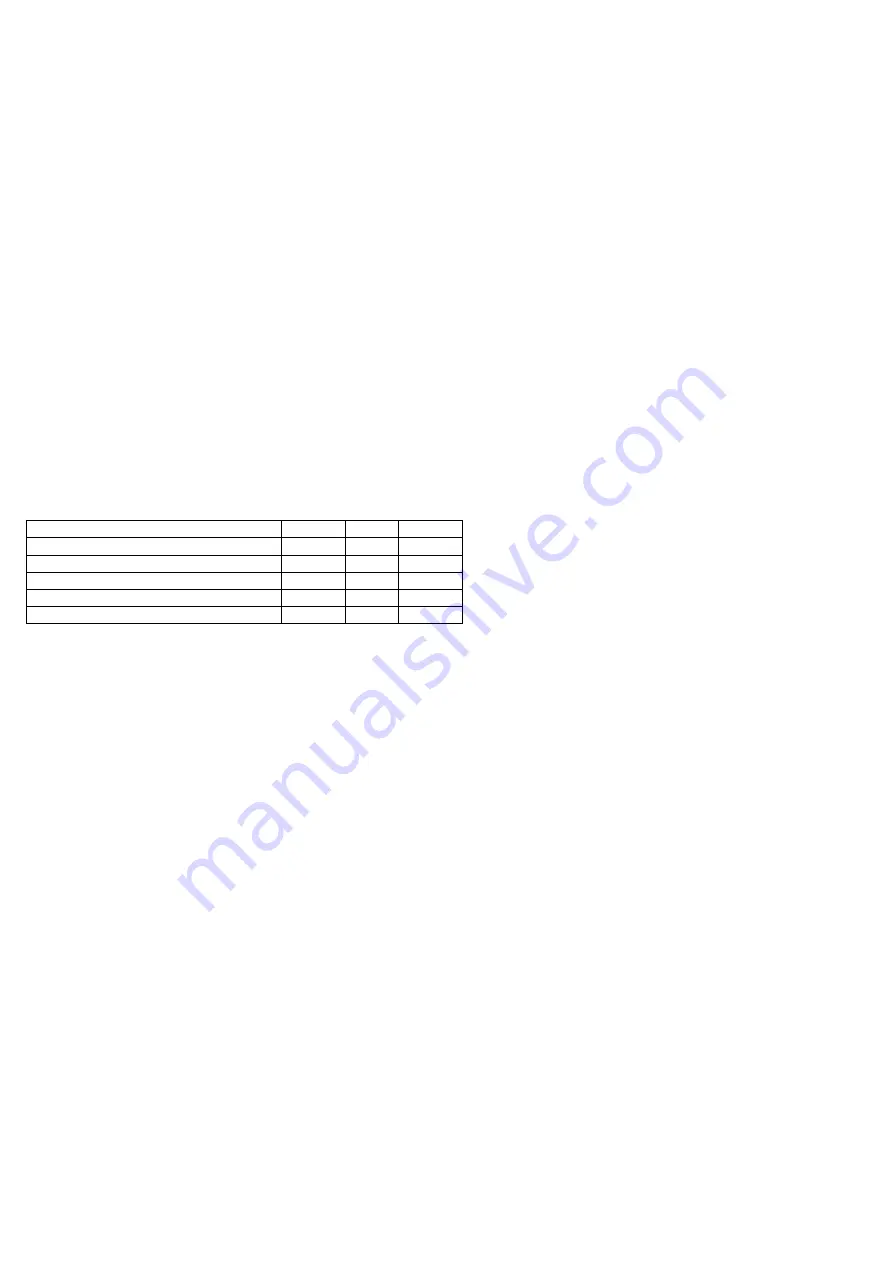

Verify the temperature differences on the heating mirror surfaces according to the following table DVS norm 2208-

1 here following table:

-

WELDING SURFACE OF THE MIRROR

∆Τ

∆Τ

∆Τ

∆Τ

1111

∆Τ

∆Τ

∆Τ

∆Τ

2222

∆Τ

∆Τ

∆Τ

∆Τ

ΤΟΤ

ΤΟΤ

ΤΟΤ

ΤΟΤ

∆Τ

∆Τ

∆Τ

∆Τ

1

1

1

1

Maximum temperature difference on the mirror surface

< 250 cm

2

5 °C

3 °C

8 °C

∆Τ

∆Τ

∆Τ

∆Τ

2

2

2

2

Temperature deviation for the adjustment

250 …. 2000 cm

2

7 °C

3 °C

10 °C

∆Τ

∆Τ

∆Τ

∆Τ

ΤΟΤ

ΤΟΤ

ΤΟΤ

ΤΟΤ

Maximum accepted difference on the mirror surface

2000 …. 5000 cm

2

11 °C

3 °C

14 °C

5000 …. 12000 cm

2

13 °C

3 °C

16 °C

> 12000

14 °C

3 °C

17 °C

7.4 Hydraulic unit

The hydraulic unit does not need particular maintenance nevertheless the following instructions must be followed:

1. Check periodically the oil level and in case add with oil type:

ESSO NUTO H 68,SHELL TELLUS 68,MOBIL DTE 26,AGIP OSO 46

The level should not be lower than 5 cm from the tank maximum level.

A checking every 15 working days it's strongly suggested.

2. Replace totally the oil every 6 months or after 500 working hours.

3. Keep clean the hydraulic unit with particular care on the tank and quick couplings.

4. Avoid to operate with rain or high humidity (95 RH %) value and temperatures below 0°C or above + 50°C.

5. During the transport it's suggested to put the metal plug instead of the plastic one.

Summary of Contents for I.T.S. PT 630

Page 1: ...I T S by Tecnodue PT 630 Edition 1208 Operating Manual ...

Page 26: ...I T S Ital Trade Services PT 630 Operating Manual 26 26 26 26 9 4 Hydraulic plan ...

Page 29: ...I T S Ital Trade Services PT 630 Operating Manual 29 29 29 29 ...

Page 31: ...I T S Ital Trade Services PT 630 Operating Manual 31 31 31 31 ...

Page 33: ...I T S Ital Trade Services PT 630 Operating Manual 33 33 33 33 ...