_ TECNOEKA Srl __________________________________________________________ use and instruction manual _

_ page 8 _________________________________________________________________________________________

-

a single-pole switch with minimum between-contacts aperture of 3 mm, sized to the

load and conforming to current legal regulations, is fitted between the appliance and the

mains in the direct connection to the mains;

-

the single-pole switch used for connection is easy to reach when the appliance is

installed;

-

the yellow/green earth wire is not interrupted by the switch;

-

the power supply, when the appliance is operating, must not deviate from the rated

voltage value by ±10%.

-

make sure that after inserting the power supply cord into the terminal block it does not

come into contact with any of the cooking range's hot parts.

Connection to the water mains - The appliance must be fed with softened drinking water,

with hardness from 0.5°F to 5°F (it is obligatory to use a softener to reduce the formation of

lime inside the cooking chamber) and pressure in the range from 150 to 250 kPa (1.5 - 2.5 bar).

Connection to the water mains should be made through the threaded 3/4" solenoid-valve on

the rear of the appliance, fitting in between a mechanical filter and an on/off tap (before you

connect the filter, allow a certain quantity of water to flow out in order to drain any waste from

the pipe).

Water drainage - One drainage tube comes out from the rear of the appliance, to drain the

cooking compartment. You should connect one pipe to the drain tube, with an internal

diameter of 30 mm (DN 30), resistant to vapour temperatures. To prevent choking, make sure

that the pipe is stiff and that it does not have any elbows along the drainage path. Furthermore,

the pipe must be at constant inclination (5% minimum) along its entire length (the length under

consideration is from the drain tube of the appliance to the drainage point and must not exceed

1 meter). The drainage pipe must lead to an open floor-level drain and, to ensure conformity to

current legal regulations on hygiene, it must not come into direct contact with the drainage

point.

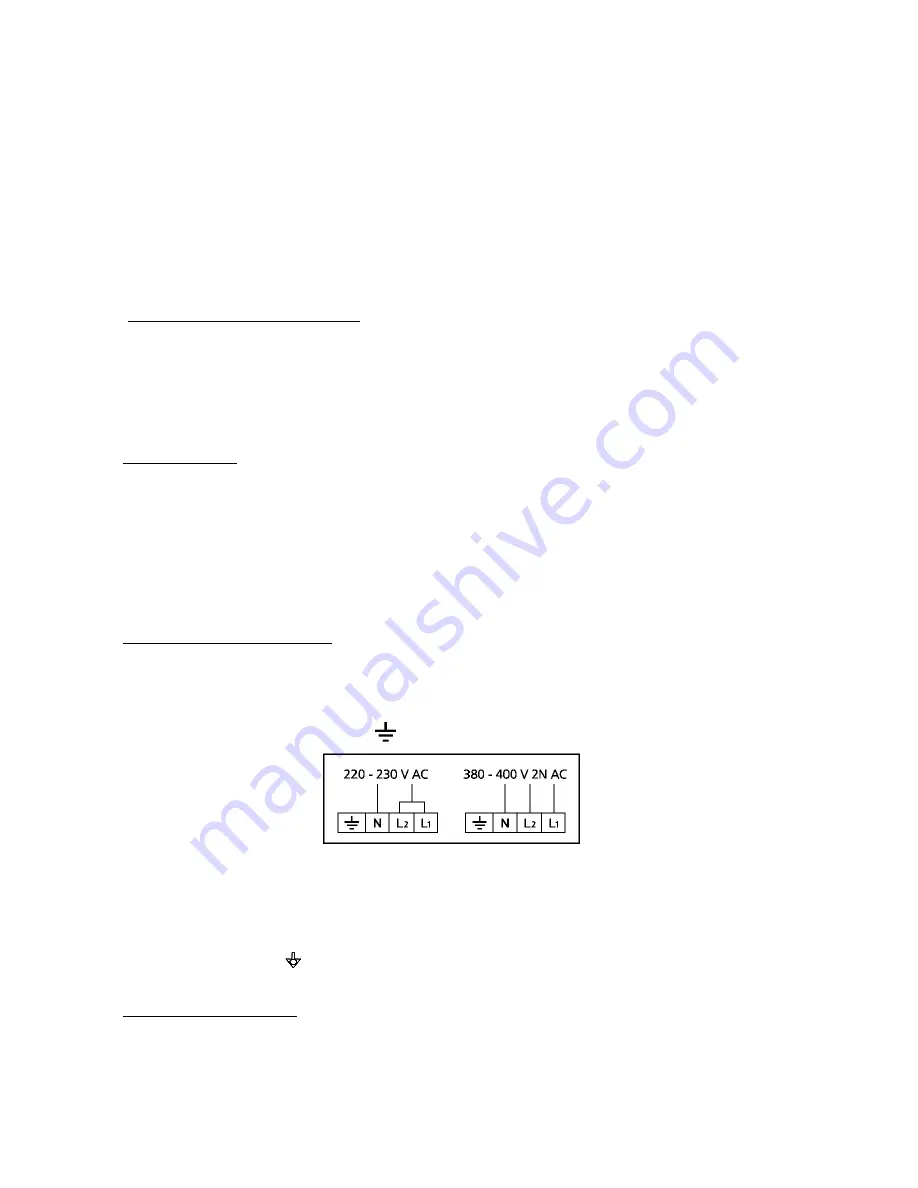

Connecting the power cable - To access the terminal board, just remove the appliance's left

side-panel. Loosen the cable gripper and allow the cable to pass through it. Arrange the

conductors so that the earth conductor is the last to detach from its terminal if the cable goes

into a state of faulty traction. Connect the phase conductors to the terminals marked “L1” and

“L2”, connecting the neutral conductor to the terminal marked "N" and the earth conductor to

the terminal marked with the symbol

according to the following lay-out:

(this electrical connection lay-out is located near the power supply terminal board ). Tighten the

cable gripper and re-fit the left side-panel of the appliance.

The appliance must be connected to an equipotential system whose efficiency must first be

checked according to current legal regulations.

This connection must be made between different appliances by using the appropriate terminal

marked with the symbol . The equipotential conductor must have a minimum diameter of 10

mm

2

The equipotential terminal is at the rear of the appliance.

Safety thermal breaker - The appliance has a manually reset safety thermal breaker. It

protects against excessive dangerous over-temperatures which could be accidentally generated

inside the appliance. If the device is tripped, it interrupts electrical power to the appliance and

thus prevents it from operating. To access this device, remove the left side-panel of the

appliance.