Overall accuracy: +/- 0,5 % fs

Sampling rate: 1 sample per second

Action: 1C type according to EN 60730-1

Compliance: ECC directive EMC 89/336 (EN 50081-1, EN 50082-1), ECC

directive LV 73/23 and 93/68 (EN 60730-1)

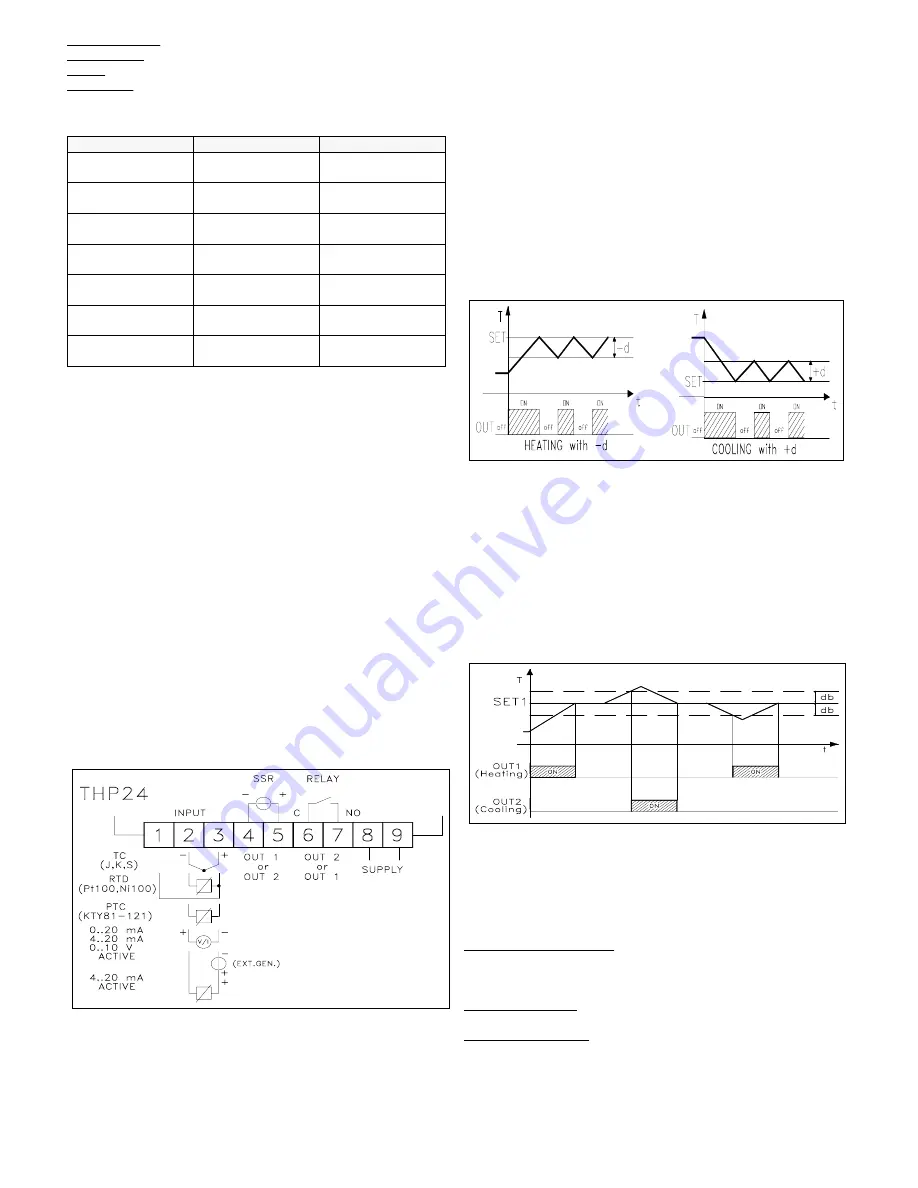

MEASUREMENT RANGE TABLE

-99.9 ... 700.0

- 999 ... 7000

4..20 mA, 0..20 mA,

0..10 V

(gener.)

---

0 ... +1600 °C

+32 ... +2912 °F

tc S (rh)

---

0 ... +1200 °C

+32 ... +2192 °F

tc K (Cr)

---

0 ... +800 °C

+32 ... 1472 °F

tc J (FE)

-50.0 ... +150.0 °C

-58.0 ... +302.0 °F

-50 ... +150 °C

-58 ... +302 °F

Ni 100 (ni)

-99.9 ... +600.0 °C

-99.9 ... +999.9 °F

-100 ... +600 °C

-148 ... +1112 °F

Pt 100 (Pt)

-50.0 ... +150.0 °C

-58.0 ... +302.0 °F

-50 ... +150 °C

-58 ... +302 °F

PTC

4 DIGIT with D.P.

4 DIGIT

PROBE

3 - INSTALLATION

MECHANICAL MOUNTING

:

The instrument, in DIN case 24 x 48 mm,

is designed for panel mounting. Make an hole 22 x 45 mm and insert the

instrument, fixing it with the provided special brackets .We recommend to

mount the gasket to obtain an IP 54 front protection. Avoid to place the

instrument in areas with humidity or dirt. Connect the instrument as far as

possible from source of electromagnetic disturbances so as motors, power

relays, relays, electrovalves,etc.

ELECTRICAL CONNECTIONS

: Carry out the electrical wiring

connecting only one wire for each terminal , according to the following

diagram, check that the power supply is the same as indicated on the

instrument and the loads current is not upper than the maximum current

admitted. The instrument, being a built in equipment with permanent

connection into a cabinet, is not furnished with internal device protecting

from overcurrent : it's recommended , therefore, to properly protect all the

electric circuits connected to the instrument, with devices (ex. fuses)

proportionate to the circulating currents. It's strongly recommended to use

cables with proper insulation, according to the working voltages and

temperatures. Furthermore, the input cable of the probe has to be kept

separate from line voltage wiring. If the input cable of the probe is

screened, it has to be connected on the ground with only one side. It is

advisable to check that the parameters are those desired before connecting

the outputs to the actuators so as to avoid malfunctioning . Whenever a

failure of the instrument could cause dangerous or damaging situations, it

should be kept in mind that the plant has to be provided with additional

devices to ensure the safety.

4 - OPERATING MODE

4.1 - ON/OFF CONTROL

The control mode of the instrument by ON/OFF mode occours on the

outputs according to the Sets point fixed, to the differential switching

points (par. "d1", "d2") and to operating modes (par. "HC1", "HC2")

programmed. For a correct functioning it is necessary to set a negative

differential switching point for reverse controls (ex.Heating processes) and

a positive differential switching point for direct controls (ex.Cooling

processes). Furtheremore the two Sets can be programmed independently

or dependently throught the parameter Sets Connection ("OCO"), and in

the case of set dependentlythe real regulation Set of output 2 will be

[Set1+Set2]. If output 2 is used as an alarm output, par. "OCO"

determines if the alarm is absolute or relative (in=absolute, di=relative)

and par. "HC2" determines if the alarm is low or high (H=low, C=high).

The operating mode can be also modified by means of outputs delay

parameter (par. "od") or Dynamic Set Point function, see the next

chapters for these functions.

4.2 - NEUTRAL ZONE CONTROL

The Neutral Zone control mode concerns both outputs and is generally

necessary for controllig a plant that possesses an Positive regulation

element (ex. Heating, Humidification etc.) and a Negative regulation

element (ex. Cooling, Dehumidification etc.) . The functioning is

determined by the Set1 (Set2 is automatically disconnected) and Neutral

Zone (par. "db"). Subsequently the regulator operates as follows: switches

off the outputs when the process value is the same as Set, switch on the

output OUT1 when the process value is under as [Set1-db], and switch on

the output OUT2 when the process value is upper as [Set1+db]. Thus the

Positive regulation element will be connected to output OUT1, while the

Negative regulation element is at output OUT2.

4.3 - PID CONTROL AND AUTOTUNING FUNCTION

PID control mode can only be carried out through output OUT 1 while

output OUT 2 can only operates by means of ON/OFF control mode with

Set 2 independent or dependended in respect with Set 1 and can therefore

be used as an alarm (see ON/OFF regulator). The PID algorithm of the

instrument is provided to program the following parameters:

For PROPORTIONAL term :

"Pb"

- Proportional Band,

"rst"

- Manual reset

"Ct"

- Cycle time.

For INTEGRAL term:

"It"

- Integral time

For DERIVATIVE term:

"dt"

- Derivative time

The instrument is set on parameters relative to PID control of standard

value. If ever these should result to be unsuitable it would be advisable to

TECNOLOGIC - THP 24

USER MANUAL (I - GB) - Vr. 01 - ISTR 00239 - PAG. 6