JULY-2014

120

MAINTENANCE

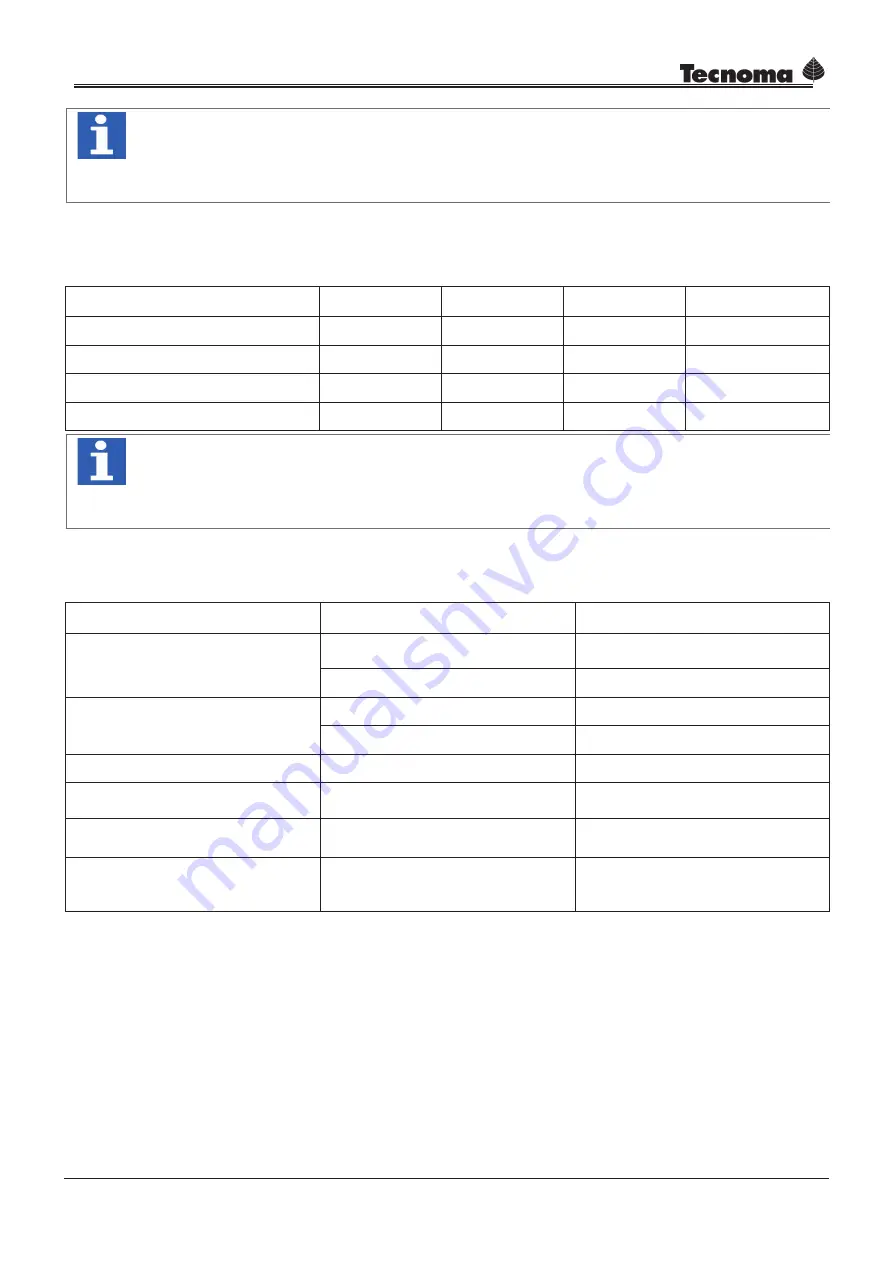

Comply with the table below at all times :

OPERATION

Every 8h

Every 50h

Every 300h

At end of season

Check oil level

U

Check membranes

D

Replace oil

D

D

Check valves

D

ACCIDENTS AND SOLUTIONS

POSSIBLE ACCIDENTS

CAUSES

SOLUTIONS

The pump doesn't reach the expected

pressure.

The rotation speed

is insuffi cient

Resume correct operation.

Valves or valve seatings faulty or dirty.

Clean or Replace

(

D

)

No pressure build up in pump.

Air intake for suction

Seal

Valves or valve seats faulty or dirty.

Clean or Replace

(

D

)

Air intake for suction

Seal

Irregular pressure

Uneven fl ow rate

Valves or valve seats faulty or dirty.

Clean or Replace

(

D

)

Noisy pump

Low oil level

Strangled or obstructed

suction.

Check suction :

Presence of water in the oil

One or more damaged membranes

Replace the damaged membrane(s).

(

D

)

CERTAIN OPERATIONS MUST BE PERFORMED By A PROFESSIONAL

COMPLy WITH THE TABLE CONCERING THE OPERATOR.

U : U

ser

D : A

thorised dealer

• To empty properly

unscrew the oil drain plug B and turn the pump rotation shaft by

hand until completely empty.

•

To fi ll up properly,

turn the pump rotation shaft by hand to remove all air and introduce

the oil slowly.

Summary of Contents for VECTIS 1000

Page 2: ......

Page 8: ...May 2015 8 MACHINE IDENTIFICATION ...

Page 40: ...May 2015 40 DECRIPTION OF THE MACHINE ...

Page 112: ...May 2015 112 MACHINE MAINTENANCE ...

Page 128: ...May 2015 128 ENVIRONMENTAL PROTECTION ...

Page 129: ...May 2015 129 Chapter 8 8 PERSONAL NOTES ...

Page 130: ...May 2015 130 PERSONAL NOTES ...