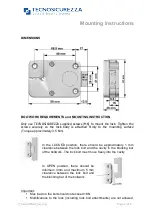

Mounting Instructions

II_StraightBolt_02_eng Page 1 of 4

CHARACTERISTICS

The StraightBolt lock can be mounted in all four

mounting directions.

The mounting dimensions are standard. The lock is delivered with metric (M6)

mounting screws. The Electronics feature a 6-digit Main code that can be changed

by the user. With the main code, a secondary code can be activated and deleted.

If a valid code has been entered, the lock electronics remove the blocking for 3

seconds and the bolt can be moved into the housing by turning an internal driving

cam with a turnable entry unit or a knob. After moving the bolt into LOCKED

position, the StraightBolt automatically secures.

Certifications: UL Type 1 – VdS class 2 – EN1300 class B

ENTRY UNITS

Pulse: T6530

Delta series: DE20xx

Bravo: BR50xx

EM35•20 Technical Manual

CHARACTERISTICS

The StraightBolt lock can be mounted in all four mounting directions. The Basic Electronics

feature a 6-digit Main code that can be changed by the user. With the main code a secondary

code can be activated and deleted. If a valid code has been entered, the lock electronic removes

the blocking for 3 seconds and the bolt can be moved into the housing by turning an internal

driving cam with a turnable entry unit or a knob. After moving the bolt to LOCKED position, the

StraightBolt automatically secures.

ENTRY UNITS

The StraightBolt is compatible with the following NL LOCK Entry units (separate technical

descriptions for Entry units are available). Entry unit spindle/cable hole on the safe door does not

have to exceed 12 mm diameter

EM35•20 Technical Manual rev. 160223

© 2016 Lock Technology Page

!

of

!

1

2

Delta Series: DE20

Bravo: BR50

Premier: PI20

(with separate knob)

!

DE20-10 Technical Manual

CHARACTERISTICS

The Delta is a low profile electronic entry with “soft touch“ rubber keypad and metal

ring to be mounted with StraightBolt lock. Cable length is approximately 30 cm.

Additional battery box is required (sold separately).

DIMENSIONS / MOUNTING INSTRUCTION

The diameter of the cable hole should be minimum 9 mm, maximum 12 mm. The

hole must be de-burred well to avoid damage to the cable.

Drill and tap door according to picture 1 drawing for the mounting plate

•

Fit the mounting plate (1) on door

using the 2x M4 mushroom-head

supplied screws (2) with "UP TO

ROTATE" oriented upwards

•

Cut spindle (5) length to exceed

8-10 mm lock mounting surface

•

Insert spindle in keypad so that

cable runs in the spindle groove.

•

Fit spring (4) and detent pin (3)

into the hole on the rear of the

keypad

•

Route the spindle through the

cable/spindle hole and move the

unit to the mounting adapters.

Rotate keypad 35-40° CCW until keypad can be fixed on the screw heads and

then rotate CW to straight up. Proceed with installing the lock.

The Delta entry unit can now not be removed!

DE20•10 Technical Manual rev. 110128

© 2011 Lock Technology BV Page 1 of 1

Delta

StraightBolt

Bolt work requirements

Lock bolt operations only allowed as described

into the drawing and max load should not

exceed 1KN.

Important:

•

Modifications to the lock (including lock bolt attachments) are not

allowed, and will void the manufacturer’s warranty and Standards

approvals.

•

No through holes on the safe door are allowed within the lock body area beside

the spindle/cable hole.

•

Lock body area should be protected against destructive attacks

EM35•20 Technical Manual

CHARACTERISTICS

The StraightBolt lock can be mounted in all four mounting directions. The Basic Electronics

feature a 6-digit Main code that can be changed by the user. With the main code a secondary

code can be activated and deleted. If a valid code has been entered, the lock electronic removes

the blocking for 3 seconds and the bolt can be moved into the housing by turning an internal

driving cam with a turnable entry unit or a knob. After moving the bolt to LOCKED position, the

StraightBolt automatically secures.

ENTRY UNITS

The StraightBolt is compatible with the following NL LOCK Entry units (separate technical

descriptions for Entry units are available). Entry unit spindle/cable hole on the safe door does not

have to exceed 12 mm diameter

EM35•20 Technical Manual rev. 160223

© 2016 Lock Technology Page

!

of

!

1

2

Delta Series: DE20

Bravo: BR50

Premier: PI20

(with separate knob)

!

DE20-10 Technical Manual

CHARACTERISTICS

The Delta is a low profile electronic entry with “soft touch“ rubber keypad and metal

ring to be mounted with StraightBolt lock. Cable length is approximately 30 cm.

Additional battery box is required (sold separately).

DIMENSIONS / MOUNTING INSTRUCTION

The diameter of the cable hole should be minimum 9 mm, maximum 12 mm. The

hole must be de-burred well to avoid damage to the cable.

Drill and tap door according to picture 1 drawing for the mounting plate

•

Fit the mounting plate (1) on door

using the 2x M4 mushroom-head

supplied screws (2) with "UP TO

ROTATE" oriented upwards

•

Cut spindle (5) length to exceed

8-10 mm lock mounting surface

•

Insert spindle in keypad so that

cable runs in the spindle groove.

•

Fit spring (4) and detent pin (3)

into the hole on the rear of the

keypad

•

Route the spindle through the

cable/spindle hole and move the

unit to the mounting adapters.

Rotate keypad 35-40° CCW until keypad can be fixed on the screw heads and

then rotate CW to straight up. Proceed with installing the lock.

The Delta entry unit can now not be removed!

DE20•10 Technical Manual rev. 110128

© 2011 Lock Technology BV Page 1 of 1

Delta

StraightBolt

Bolt work requirements

Lock bolt operations only allowed as described

into the drawing and max load should not

exceed 1KN.

Important:

•

Modifications to the lock (including lock bolt attachments) are not

allowed, and will void the manufacturer’s warranty and Standards

approvals.

•

No through holes on the safe door are allowed within the lock body area beside

the spindle/cable hole.

•

Lock body area should be protected against destructive attacks

ST series: ST40xx

Entry Delay: T8530