User’s manual

- TECO 22 - 23 - 25 - 27 Special

21

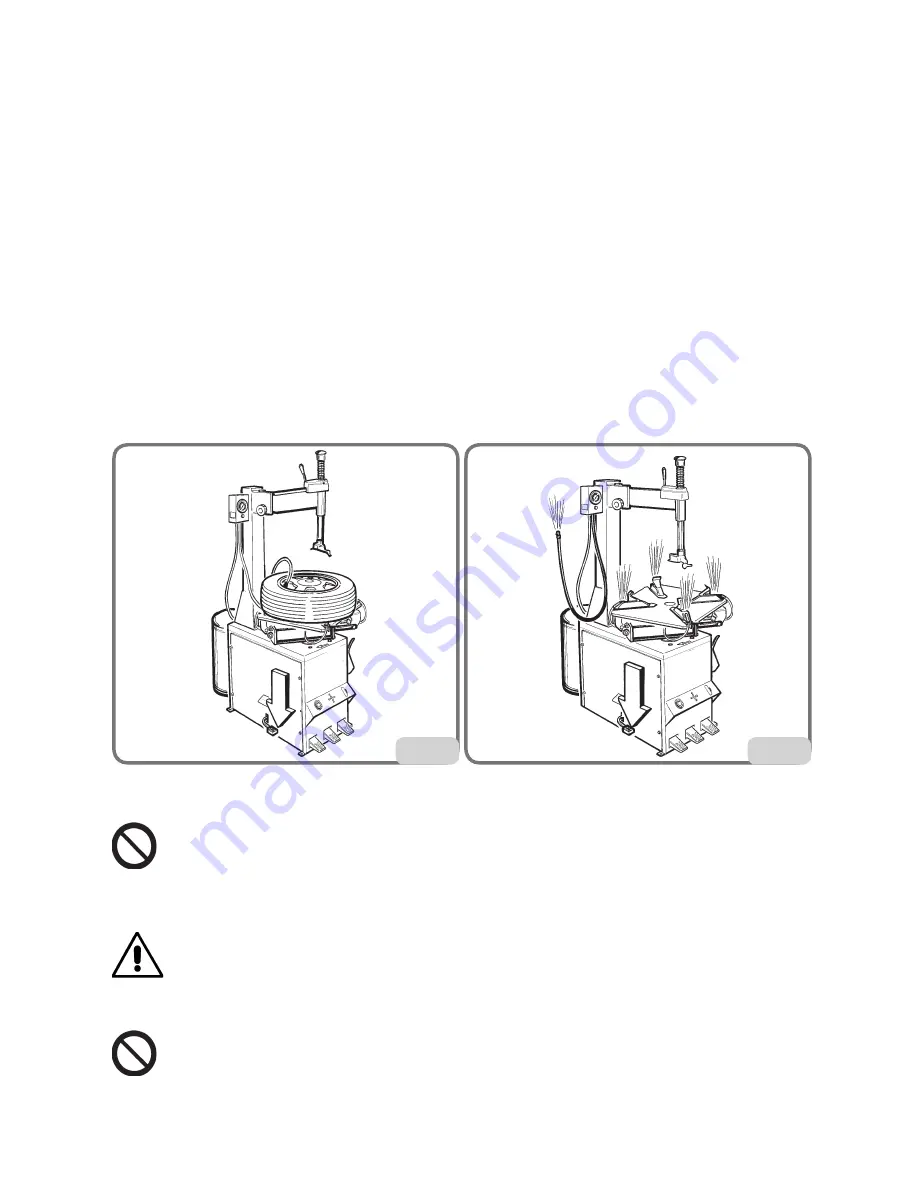

Inflating tubeless tyres

(T.I. versions only)

WARNING

Before carrying out the operations described below, always make sure that there is no dirt,

dust or other impurities on the jaws near the air outlet holes.

- Make sure that the wheel is secured to the table top with inside clamping.

- Pull the horizontal arm all away out.

- Lower the vertical bar till it touches the rim.

- Lock the horizontal and vertical arms in the positions described on Fig.20.

- Connect the Doyfe inflator chuck on the air hose to the valve stem.

- Hold the tyre with your hands and lift it until there is a slight gap between the lower bead and bottom

edge of the rim in order to close the upper bead and the top of the rim.

- Press the inflation pedal fully down for a short period to the bead seating position (fig.20). The tyre

will expand and the beads will seat.

- Continue to press the pedal in the inflation position (fig.21) until the beads are completely sealed.

Note: to improve the operation of the tubeless tyre inflation system the compressed air line pressure

must be between 8/10 bar.

MAINTENANCE

CAUTION

The “Spare parts” handbook does not authorize users to carry out work on the machine with the

exception of those operations expressly described in the user manual. It only enables users to

provide the technical assistance service with precise information in order to minimize delays.

WARNING

TECO declines all liability for claims deriving from the use of non-original spare parts or

accessories.

CAUTION

Any operation intended to modify the setting value of the relief valves or pressure limiter is forbidden.

The manufacturer declines all liability for damage resulting from tampering with these valves.

20

21