1.

Introduction

This document describes the main design specification of the E510s Safe Torque Off ( STO ) and

the requirements for its installation and integration within safety related applications.

The correct Installation and integration of the E510s STO is the responsibility of the Installer

and it is expected that the installer follows the safety guide and is a trained technician and

experienced in the design of safety systems.

E510s STO (Safe Torque Off) circuit and function is certified by Tuv to:

Safety Integrated category SIL2 according to EN/IEC 62061, IEC 61508, EN61800-5-2

Performance level. Category 3/ Pl(d). according to EN/ISO 13849-1 Stop category 0.

According to EN60204-1

2.

Safety-Related Requirements

2.1 Directives

IEC/EN 61800- 5-2 : 2007

Adjustable Speed Electrical Power Drive Systems.

Part 5-2: Safety Requirements – Functional

EN ISO 13849-1: 2008

Safety of Machinery – Safety-related parts of control systems.

Part 1: General Principles for Design

IEC 61508- 1~7

Functional Safety of Electrical/Electronic/Programmable Electronic

Safety-related systems

IEC 62061: 2005

Safety of Machinery – Functional safety of safety-related electrical,

electronic and programmable electronic control systems

EN 60204-1

Safety of machinery - Electrical equipment of machines. General

requirements.

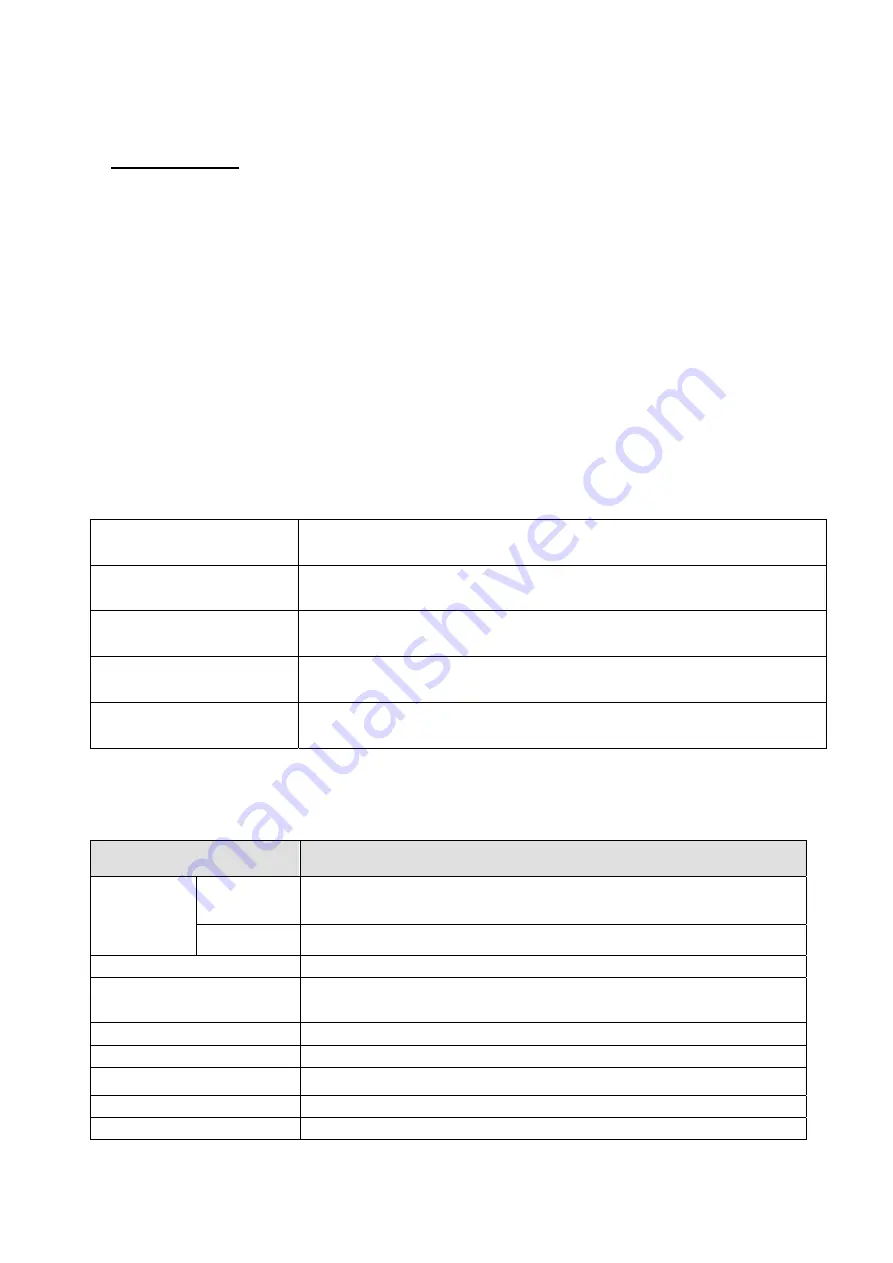

2.2 Installation Environment

E510s safety stop function should only be used under the following condition and

environment.

Item

Condition

Temperature

range

Operation

-10°C~50°C inside distributor (without dust cover)

-10°C~40°C inside distributor (with dust cover)

Storage

-20°C to +60°C

Ambient humidity

95%RH maximum (non-condensing)

Shock

1G. (9.8m/s²) for 20Hz and below.

0.6G (5.88m/s²) from 20Hz to 50Hz (Compliance with IEC 60068-

Altitude

maximum 1000m above sea level

Atmosphere

Indoors (without corrosive gas, flammable gas, oil mist, dust and

Over voltage category II or less

Pollution degree

II or less

Mounting

wall mounting / vertical orientation

Table 1.

Summary of Contents for E510-201-SH

Page 1: ......

Page 28: ...3 14 b 200V 2HP 1 3PH 200V 3HP 20HP 400V 3HP 25HP IP20 NEMA1 ...

Page 29: ...3 15 c 200V 25HP 400V 30HP d 200V 30HP 40HP 400V 40HP 75HP ...

Page 51: ...3 37 3 5 Standard Wiring 10V AI1 AI2 AGND E P P ...

Page 72: ...4 6 4 1 4 Example of keypad operation Example 1 Modifying parameters ...

Page 74: ...4 8 4 1 5 Operation control ...

Page 206: ...4 140 Acceleration Deceleration calculation of mode 2 ...

Page 316: ...4 250 6 Timer mode 6 FLASH Timer mode 2 7 Timer mode 7 FLASH Timer mode 3 ...

Page 424: ...REVISIONS Date Manual Number Revision May 2017 4KA72X645T01 First edition ...

Page 425: ......