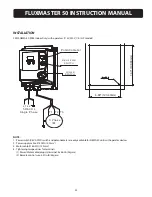

INSTALLATION

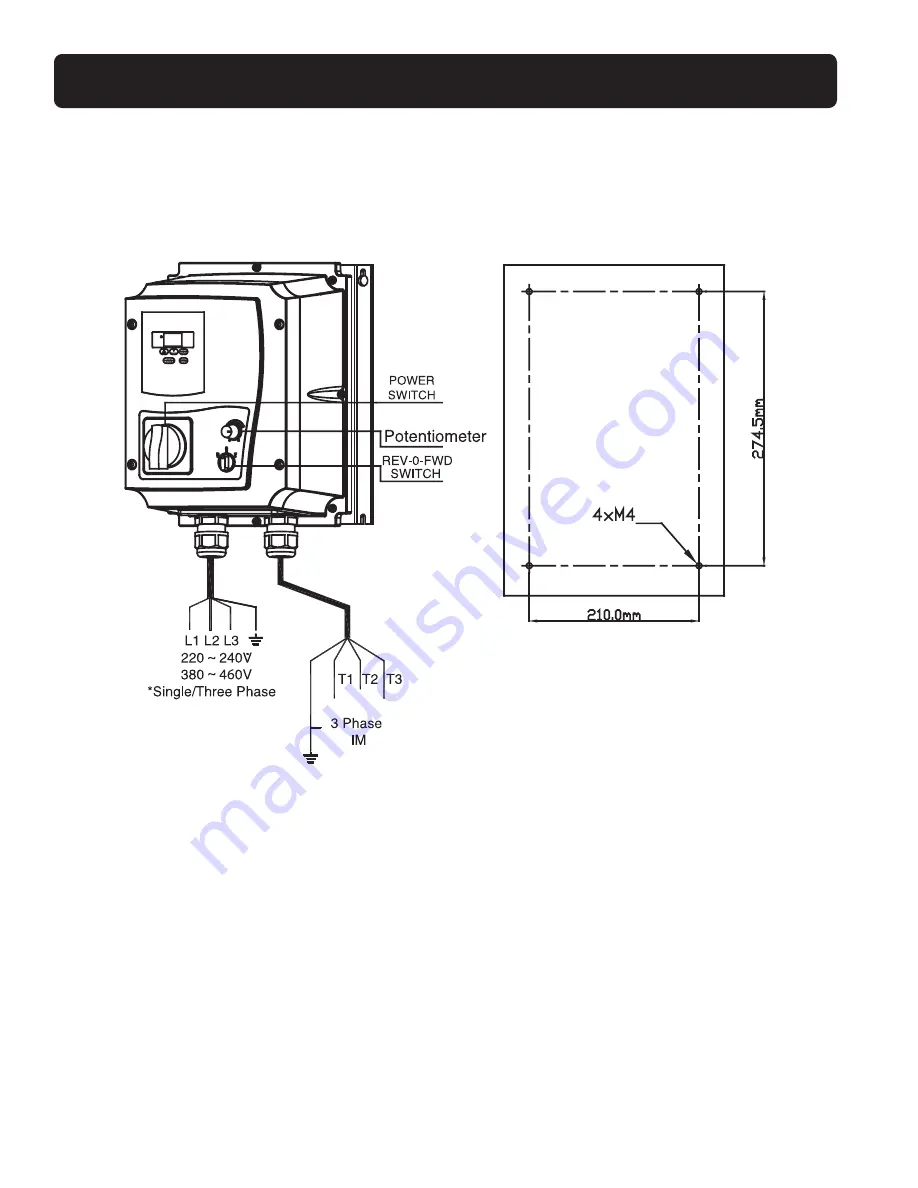

FM50 NEMA 4X (IP65 Indoor Duty) with operators (230V 2, 3HP, 460V 1 - 3HP models)

NOTE :

1. Power switch, REV-0-FWD switch and potentiometer are only for NEMA 4X units with operator devices.

2. Power supply cable: 230V #12 AWG (3.5mm

2

); 460V #16 AWG (1.25mm

2

)

3. Motor cable: 230V #14 AWG (2.0mm

2

); 460V #16 AWG (1.25mm

2

)

4.Tightening torque values for terminals:

(1). Power/Motor cable (TM1, TM3) Terminal: 6.94in-lb (8kg-cm)

(2). Remote control wire: 3.47in-lb (4kg-cm)

(3). Outer cover (M4): 6.94in-lb (8kg-cm)

*Models FM50-202-N4FS & FM50-203-N4FS with operator devices are single phase input only.

28

FLUXMASTER 50 INSTRUCTION MANUAL

Summary of Contents for FM50101-X

Page 1: ...www tecowestinghouse com Instruction Manual User Manual...

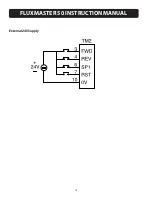

Page 18: ...External 24V Supply 18 FLUXMASTER 50 INSTRUCTION MANUAL...

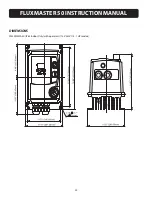

Page 33: ...33 FLUXMASTER 50 INSTRUCTION MANUAL 2 6 Mounting Instructions...

Page 53: ...4 Troubleshooting Procedures 53 FLUXMASTER 50 INSTRUCTION MANUAL 4 1 Flow Chart...

Page 54: ...FLUXMASTER 50 INSTRUCTION MANUAL Continued 54...

Page 55: ...FLUXMASTER 50 INSTRUCTION MANUAL Error handling of fault indication of OC OL 55...

Page 56: ...Error handling of fault indication of OV LV 56 FLUXMASTER 50 INSTRUCTION MANUAL...

Page 57: ...57 FLUXMASTER 50 INSTRUCTION MANUAL 1 Motor inoperative...

Page 58: ...FLUXMASTER 50 INSTRUCTION MANUAL 58 2 Motor overheat...

Page 59: ...FLUXMASTER 50 INSTRUCTION MANUAL 3 Unstable motor operation 59...

Page 66: ...Notes 66 FLUXMASTER 50 INSTRUCTION MANUAL...