15

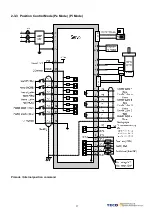

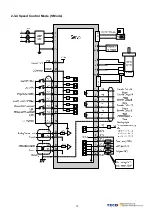

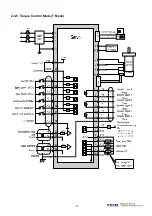

2-1-2 Wiring for Servo Drives

The wire material must go by “Wiring Specifications.”

Wiring Length: Command Input Wire: Less than 3m.

Encoder Input Wire: Less than 20m.

The Wiring goes by the shortest length.

Please wire according to the standard wiring schema. Don’t connect if no using.

Please use the NFB to meet IEC (or UL Certification) between power supplier and servo drive.

In the addition of supplying max. voltage, the capability of short circuit current must below 5000Arms, If there is

posibility t.

Drive output terminals (U,V,W) must be connected to motor correctly. Otherwise the servo motor will abnormally

function.

Shielded cable must be connected to FG terminal.

Don’t install the capacitor or Noise Filter at the output terminal of servo drive.

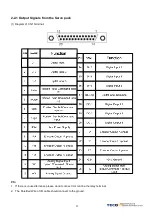

At the control-output-signal relay, the direction of surge absorb diode must be correctly connected, otherwise it

can not output signal, and cause the protect loop of emergency-stop abnormal.

Please do these below to avoid the wrong operation from noise:

Please install devices such as the insulated transformer and noise filter at the input power.

Keep more than 30 cm between Power wire (power cable or motor cable…etc.) and signal cable, do not

install them in the same conduit.

Please set “emergency-stop switch” to prevent abnormal operation.

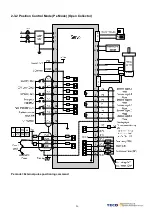

After wiring, check the connection-situation of each joint (ex: loose soldering, soldering point short, terminal order

incorrect…etc.). Tighten the joints to confirm if surly connected to the servo drive, if the screw is tight. There can

not be the situations such as cable break, cable pulled and dragged, or be heavily pressed.

* Especially pay attention to the polarity between servo motor wiring and encoder.

There is no necessary to add extra regeneration resistance under general situation. If there is any need or

problem, please connect to distributor or manufacturer.