N3 Drive Operations Manual

Routine Periodic Inspection

97

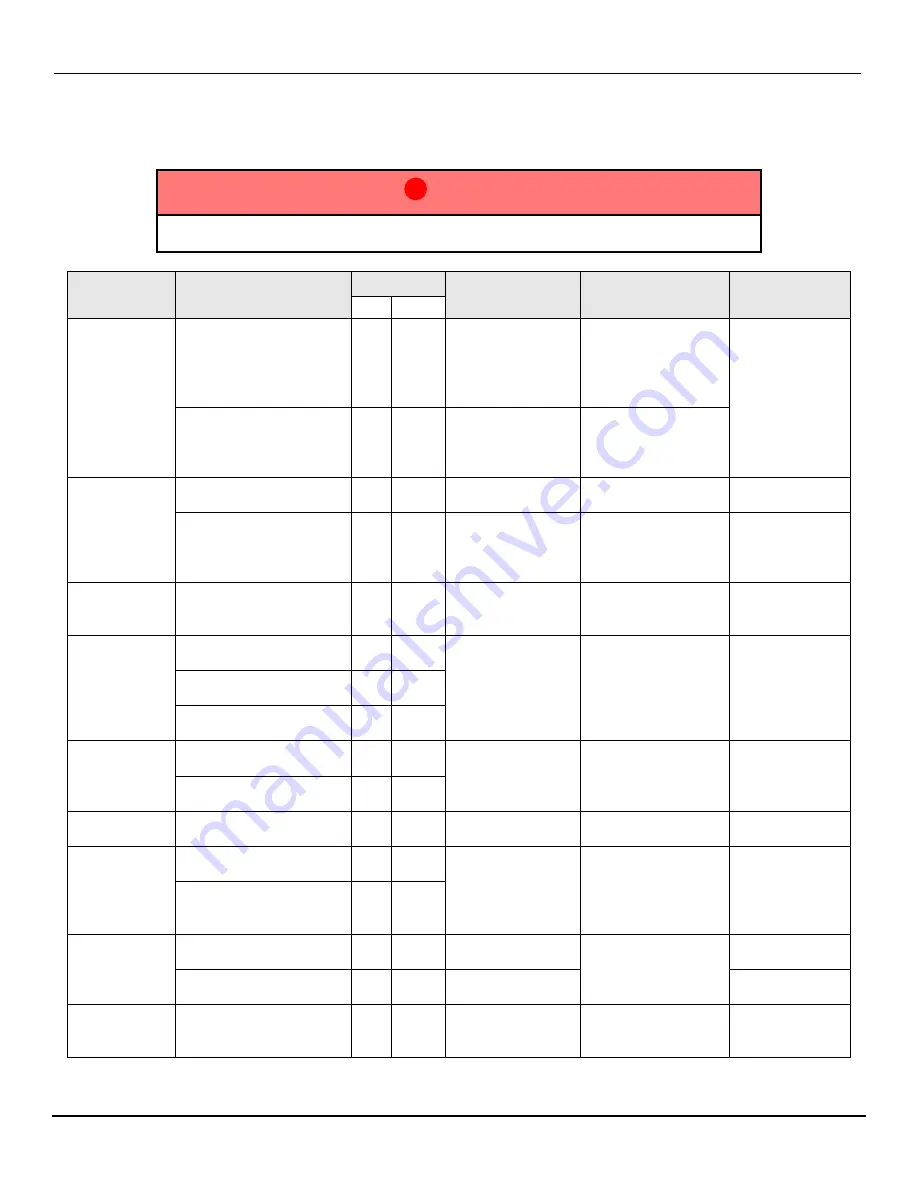

23.0 Routine periodic inspection

To ensure safe and secure operations, check and maintain the inverter and motor at regular intervals, the table below

lists the suggested items to be checked on a periodic basis.

Items

Details

Check

Methods

Criteria

Action

Daily Yearly

Ambient

conditions

around the

drive

Confirm that the

temperature and

humidity is within

specification

x

Measure with

thermometer

and hygrometer

Temperature:

-10

– 40

o

C

(14-120

℉

)

Humidity:

Below 95% RH

Improve the

ambient or

relocate the

drive.

Are there

flammable or

corrosive materials

in the vicinity?

x

Visual check

Keep area clear

Installation and

grounding of

the inverter

Any excessive vibration

from the machine ?

x

Visual, hearing

check

No vibration

Secure hardware

Is the ground

bonding resistance

correct?

x

Measure the

resistance

with a multi-

tester

200V series: below

100Ω

400V series: below

10Ω

C grounding

Input power

voltage

Is the voltage correct?

x

Measure the

voltage with a

multi-tester

Voltage must

conform with the

specifications

Correct input

voltage

External

terminals and

internal

mounting

screws of the

inverter

Are secure parts

loose?

x

Visually check &

Check with a

screwdriver

Secure terminals

and no rust present

Secure or return

for repair

Is the terminal base

damaged?

x

Visual rust stains

present?

x

Internal wiring

of the inverter

Any unusual bends or

breaks?

x

Visual check

No abnormalities

Replace or return

for repair

Any damage of the

wire insulation?

x

Heat sink

Excessive dust or

debris

x

Visual check

Clean surfaces

Clean up debris

or dust

Printed circuit

boards &

power

modules

Excessive dust or

debris.

x

Visual check

Clean surfaces with

no discoloration.

Clean or replace

the circuit board

or power

modules

Discolored,

overheated, or

burned parts

x

Cooling fan

Unusual vibration

and/or noise

x

Visual or

hearing check

Clean surfaces

Replace the

cooling fan

Excessive dust or

debris

x

Visual check

Clean fan

Capacitor

Any unusual odor or

leakage

x

Visual check

No abnormalities

Replace

capacitor

or

inverter

!

DANGER

To prevent injury to personnel and damage to the equipment, wait 5 minutes after

the “charge indicator” extinguishes before touching any parts.