A LOOK AT SERVICE SAFETY

Operation

115

IV.

Control of Liquid Refrigerant

Floodback to the Compressor

During Operation

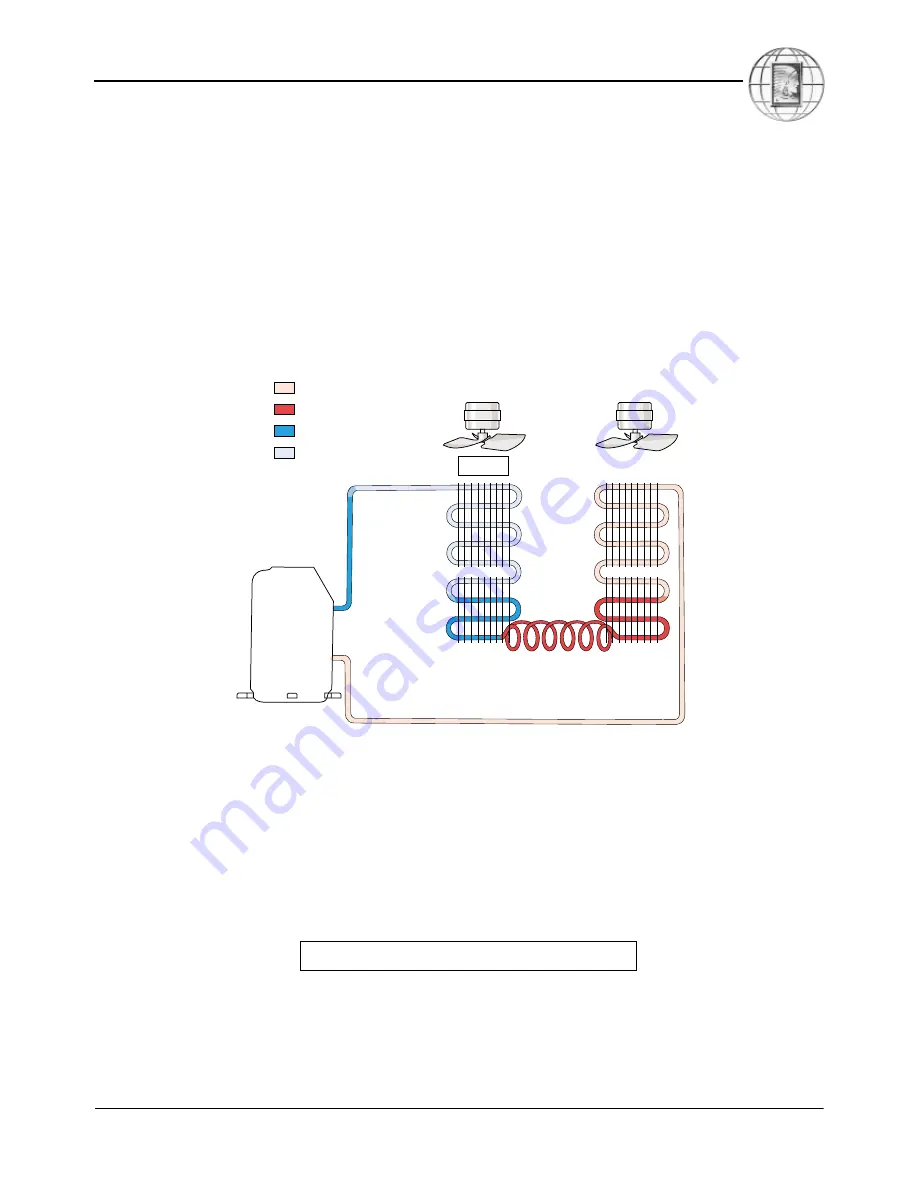

Liquid floodback during operation (see Figure 6-9)

can be caused by fan failure or dirty clogged filters

that can reduce the heat transfer rate to such a point

that the liquid refrigerant floods through, instead of

vaporizing. When this situation occurs, liquid

refrigerant may enter the compressor under condi-

tions which result in separation of the oil and refrig-

erant. This separation may result in an

accumulation of the refrigerant under the oil (see

Figure 6-10). Thus, when the compressor is started,

the first liquid to be pumped to the bearings will

probably be refrigerant, not oil. Even if this oil-

refrigerant separation does not occur, the large

amount of liquid refrigerant in the crankcase will

instantly vaporize and boil away the oil charge when

the compressor starts (see Figure 6-11). Thereby

leaving the compressor oil-starved for many seconds

(see Figure 6-12).

Figure 6-9.

Liquid refrigerant floodback to the compressor.

High Pressure Gas

High Pressure Liquid

Low Pressure Liquid

Low Pressure Gas

Fan

Fan

Evaporator

Condenser

Compressor

Expansion Device

Filter

Note: This page is designed to be in color