A LOOK AT SERVICE SAFETY

Compressor Motor and Component Information

17

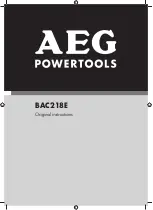

C. Capacitor Start and Run (CSR)

This motor arrangement uses a start capacitor and a

run capacitor in parallel with each other and in

series with the motor start winding. This motor has

high starting torque, runs efficiently, and is used on

many refrigeration and air conditioning applications

through 5 HP. A potential relay removes the start

capacitor from the circuit after the motor is up to

speed. This motor may use either:

•

an external thermal protector, or

•

an internal thermal protector.

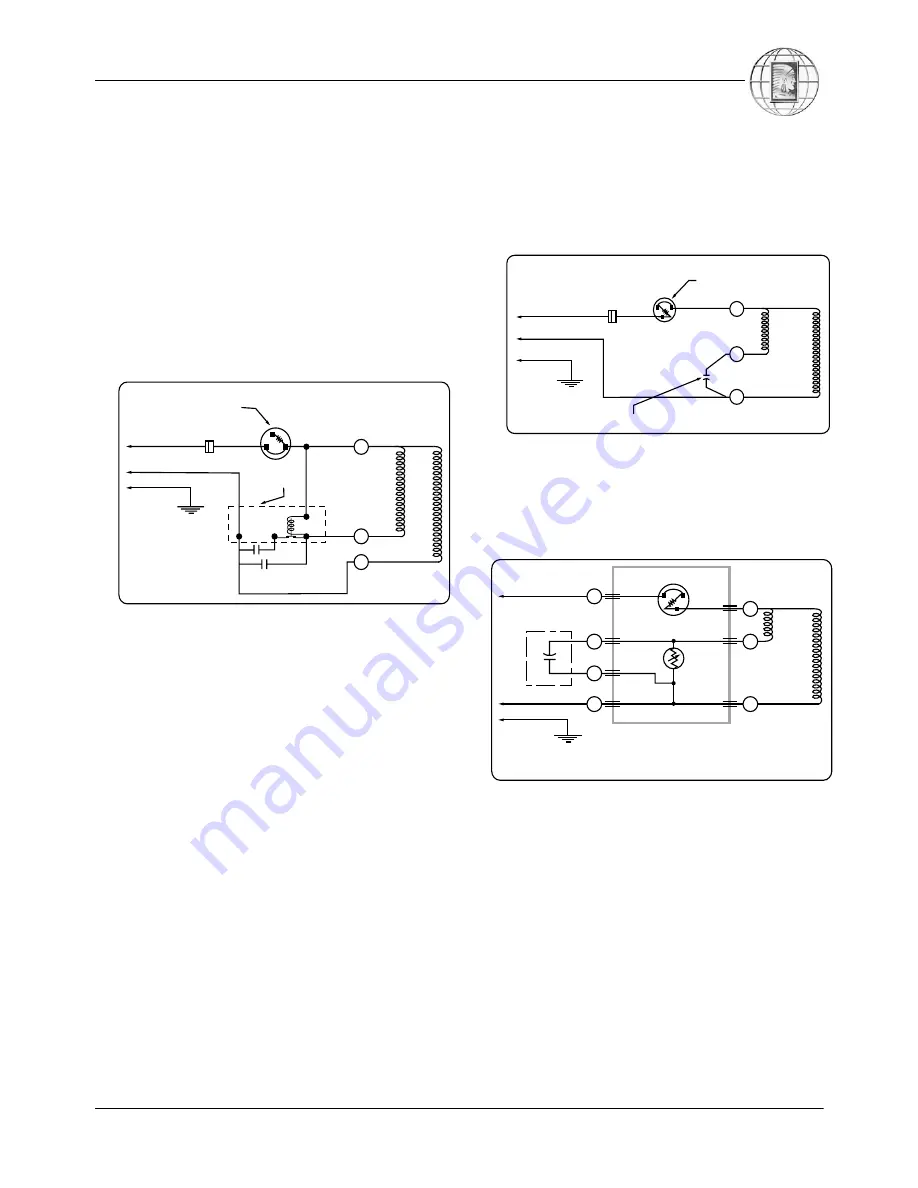

D. Permanent Split Capacitor (PSC)

Here a run capacitor is in series with the start wind-

ing. Both run capacitor and start winding remain in

the circuit during start and after motor is up to

speed. This normal starting torque motor is suffi-

cient for capillary and other self-equalizing systems.

No start capacitor or relay is necessary. For addi-

tional starting torque, a proper start assist kit may be

added (see Figure 3-6). Some start assist kits may

include:

•

a wired-in Positive Temperature Coefficient

(PTC) relay, or

•

a module Positive Temperature Coefficient

(PTC) relay.

This motor may use either:

•

an external thermal protector, or

•

an internal thermal protector.

PSC motors are basically air conditioning compres-

sor motors and are very common up through 5 HP.

Figure 3-4.

CSR motor diagram.

Relay -

Potential

Compressor -

Unit Ground

Line 1

Line 2

Ground

Star

t

Winding

Main

Winding

Control

External or Internal

Thermal Protector

C

S

R

Figure 3-5.

PSC motor diagram.

Compressor -

Unit Ground

External or Internal

Thermal Protector

Run Capacitor

Line 1

Line 2

Ground

Star

t

Winding

Main

W

inding

Control

C

S

R

Figure 3-6.

PSC motor diagram with start assist kit

that includes a module PTC relay.

Line 1

Line 2

Ground

Compressor -

Unit Ground

PTC

Relay

Plug-In

Run Capacitor

PTC Starting and

Protector Package

Thermal Protector

Star

t

Winding

Main

Winding

C

C

C

2

C

1

N

S

R