A LOOK AT SERVICE SAFETY

Servicing

41

III.

Troubleshooting Chart

For your safety, read and follow the “General Service

Safety Precautions” (on pages 2-7), as well as the ref-

erenced troubleshooting procedures in this chart.

The “General Service Safety Precautions” section

provides information on the following topics:

•

Trained Personnel Only

•

Terminal Venting and Electrocution

•

Refrigerants and Other Chemicals

•

Compressor Removal

•

System Flushing, Purging, and Pressure Testing

for Leaks

•

System Charging

•

Prevention of Water-Utilizing System Explo-

sions

•

Start Capacitor Overheating

•

System Evacuation

This Troubleshooting Chart is not designed to

replace the training required for a professional air

conditioning/refrigeration service person, nor is it

comprehensive.

If you have any questions about returns under war-

ranty, see “Is your Compressor Eligible for Return

Under Warranty?” on page 83.

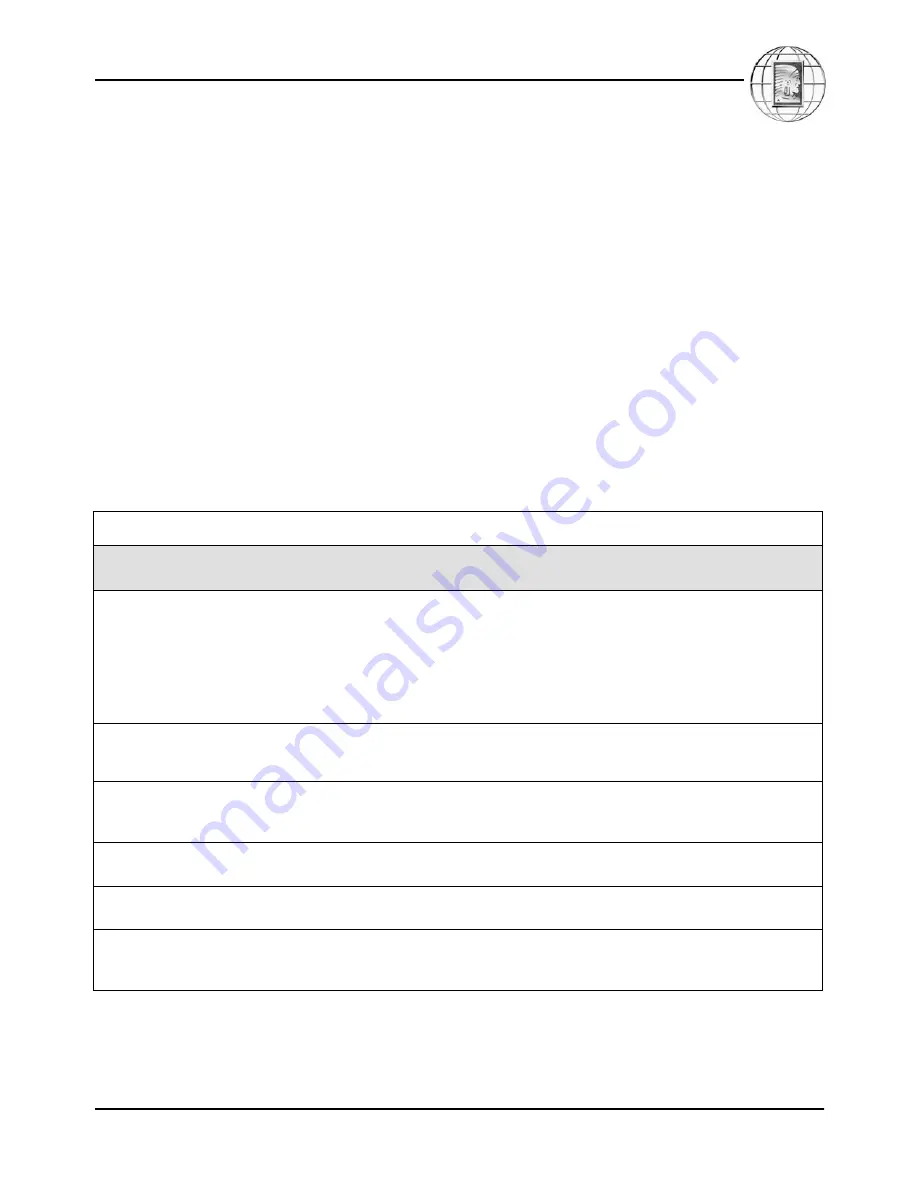

Complaint

Possible Causes

Response

A

Compressor will

not start—no hum

1. System component not functioning

properly:

a. Control/contactor stuck in open

position.

b. Control off due to cold location.

c. Thermostat not functioning properly.

a. Refer to the original equipment

manufacturer (OEM) service

information.

b. Same as “a”.

c. Same as “a”.

2. Line disconnect switch open.

Close the start switch or the disconnect

switch.

3. Circuit breaker tripped or fuse open or

removed.

Before resetting breaker or replacing fuse,

see “Identifying Compressor Electrical

Problems” on page 47.

4. Thermal protector not working properly.

See “Identifying Compressor Electrical

Problems” on page 47.

5. Wiring improper or loose.

Check against wiring diagram and wire

properly.

6. Compressor motor has a ground fault

(also known as a short circuit to

ground).

See “Identifying Compressor Electrical

Problems” on page 47.