9

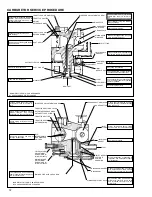

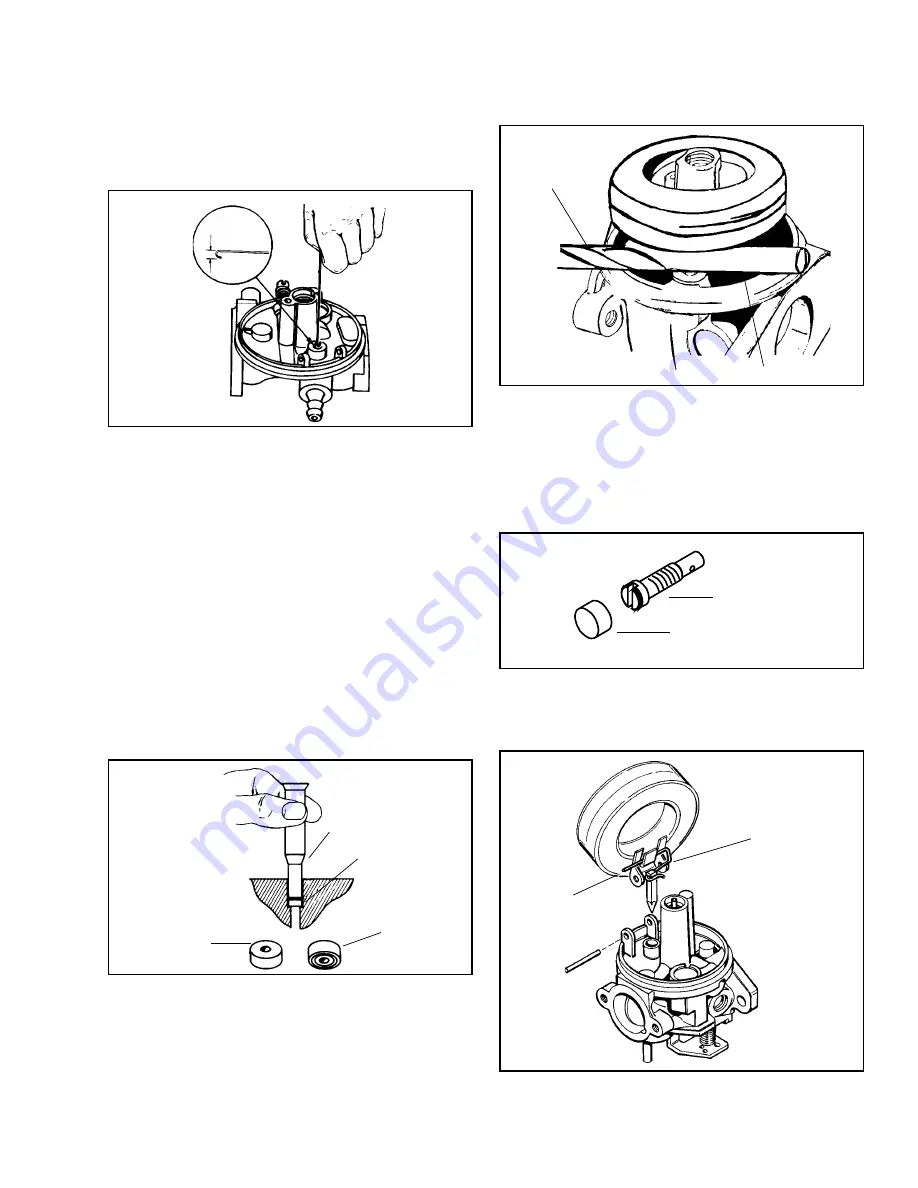

INLET NEEDLE AND SEAT (FLOAT CARBURETORS).

Tecumseh carburetors are built with removable seats

made out of a material called VITON

®

. These seats

are easily removed by bending the end of a paper

clip or wire with a 3/32" hook or use a #4 crochet

hook. Push the hook through the hole in the center

of the seat and remove it. Never reuse the old seat,

always replace it with a new seat.

To install a new seat, make sure the seat cavity is

clean, then moisten the seat with a drop of oil to help

it slide into place. Position the seat with the grooved

side of the seal down and carefully push the seat

into its cavity with a 5/32" flat punch until it bottoms

out.

NEEDLE AND SEAT POP-OFF TEST

To test the pop-off pressure, remove the carburetor

from the engine. Be sure to drain any fuel into an

approved container. Invert the carburetor and remove

the float bowl. Place a drop of an oil based product

such as WD-40 on the tip of the needle valve. Using

a commercially available 0-30 psi pump and gauge,

attach the pumps hose to the carburetor inlet. Apply

approximately 6 psi or until the needle pops off the

seat. The needle should seat at 1.5 psi or greater for

a minimum of 5 minutes. If the minimum 1.5 psi cannot

be maintained for this period of time, then service to

the needle and seat is required.

HOOK END

3/32"

DRIVE IN UNTIL

SEAT RESTS ON

BODY SHOULDER

INSERT THIS

FACE FIRST

INLET NEEDLE

SEATS AT THIS

POINT

5/32" FLAT PUNCH

SEAT

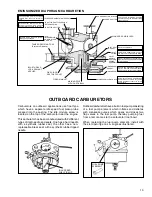

FLOAT HEIGHT SETTINGS

Previously the float height was set by using a 670253A

float setting tool. The new float setting will require an

11/64" drill bit. The procedure for setting the float height

is as follows. Remove the bowl gasket, then hold the

carburetor in the inverted position. Place the drill bit

across the carburetor body opposite and parallel to

the float hinge pin. Adjust the float height by bending

the tab on the float until it touches the bit.

If the required adjustment is minor, the tab adjustment

may be made without removing float and carefully inserting

a small bladed screwdriver to bend the tab. Be careful

not to damage other parts.

RIM

11/64" DRILL BIT

The inlet needle hooks onto the float tab by means of

a spring clip. To prevent binding, the long, straight,

open end of the clip must face the choke end of the

carburetor as shown.

IDLE RESTRICTOR

CAP

THROTTLE END

CHOKE END

LONG END

OF CLIP

CLIP

The idle on the Series 8 is metered using a threaded

restrictor (See illustration). Proper torque of this restrictor

is critical, it should be torqued to 5-8 in. lbs. or .5 to

1 nm, or it may vibrate loose. When the restrictor is

placed in the idle circuit passage it is capped with a

tamper resistant plastic cap. If the jet is removed for

cleaning it must be recapped to prevent tampering

when it is re-installed.

Summary of Contents for AH520 -

Page 67: ...64...