15

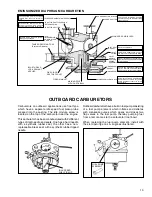

Emission grade carburetors will have fixed main and

idle circuits. The absence of adjustment screws indicate

fixed jets with no adjustments necessary.

CARBURETOR ADJUSTMENTS

IDLE SPEED ADJUSTMENT

This screw is located on top of the carburetor and

contacts the throttle. To pre-set the idle speed, back

out the screw, then turn in until the screw just touches

the throttle lever. Finally, turn the screw in one (1)

turn. Once the engine is running and brought up to

operating temperature (3-5 minutes), the final idle R.P.M.

can be adjusted with the aid of a tachometer.

FLOAT TYPE-FIXED MAIN, IDLE ADJUST

Turn the mixture adjusting screw in (clockwise) finger

tight, then one (1) turn out (counterclockwise). This

setting is approximate and will be enough to allow

the engine to start so that final carburetor adjustments

can be made. Start the engine and allow it to warm-

up for approximately 5 minutes.

Do not adjust the

carburetor with the engine cold.

NOTE:

If the engine falters or stops after the choke

lever is moved to the "OFF" position, open the mixture

adjusting screw 1/4 turn counterclockwise and restart

the engine.

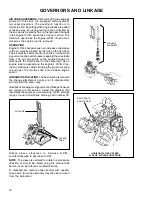

With the engine running, place the speed control in

the "slow" position. Turn the mixture adjusting screw

clockwise until the engine starts to falter, remember

this location. Next turn the screw counterclockwise

until the engine start to sputter or drops in R.P.M.,

remember this location. Now turn the screw clockwise

until it is halfway between these two locations. This

will be the optimum carburetor setting.

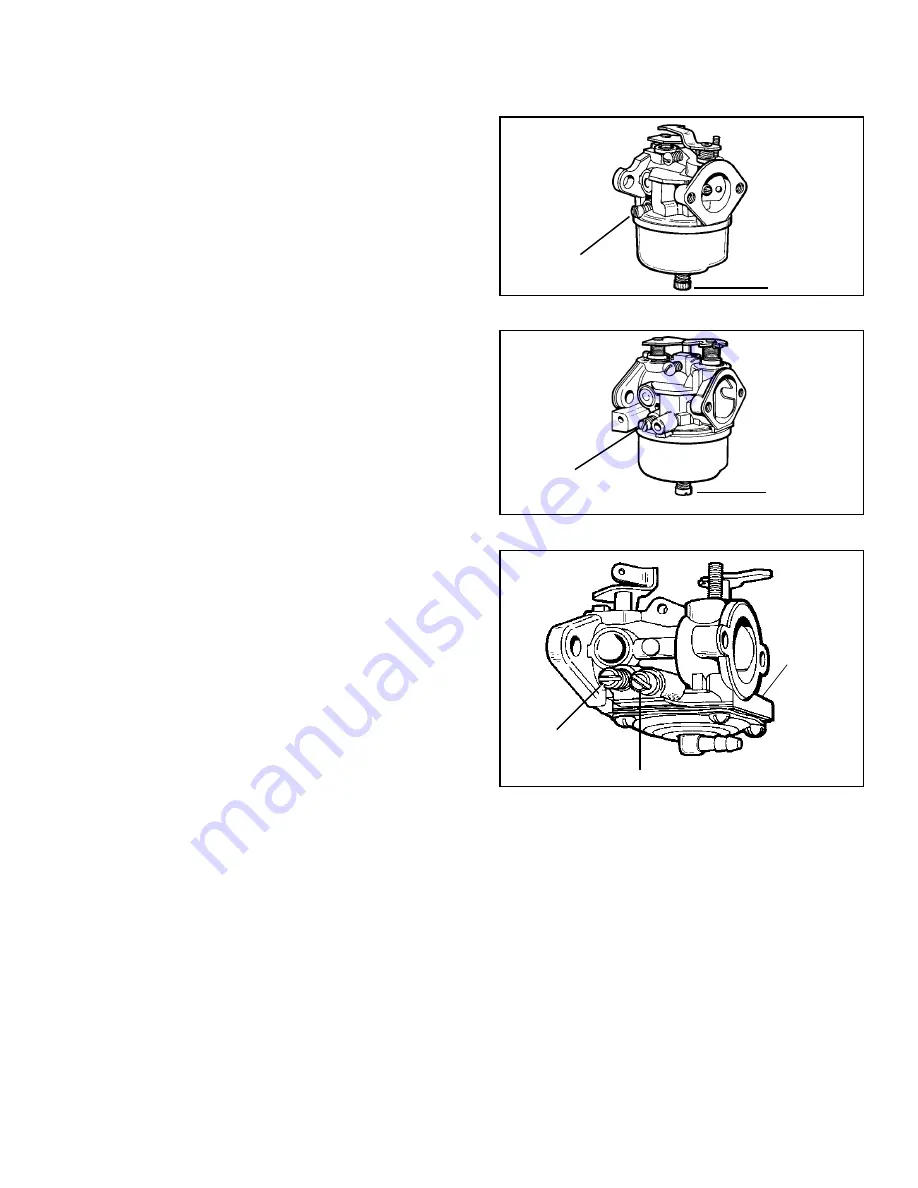

DIAPHRAGM - SINGLE AND DUAL ADJUSTMENT

Turn the mixture adjustment screw(s) clockwise finger

tight, then one (1) turn counterclockwise. This setting

will allow the engine to be started so that the carburetor

can be fine tuned.

Do not adjust the carburetor when

the engine is cold.

Start the engine and let it warm-up for approximately

5 minutes. If the engine falters or stops after the choke

lever is moved to the "OFF" position, turn the adjusting

screw 1/4 turn counterclockwise and restart the engine.

NOTE:

On dual adjust, the first adjustment must be

made with the main mixture screw.

With the engine running, turn the mixture adjustment

screw clockwise until the engine starts to falter,

remember this location. Next turn the screw

counterclockwise until the engine starts to sputter or

drop in R.P.M., remember this location. Now turn the

screw clockwise until it is halfway between these two

locations. This will be the optimum carburetor setting.

With dual adjust carburetor, repeat the above steps

for the second (idle) mixture adjusting screw.

CARBURETOR ADJUSTMENTS

SERIES I

IDLE MIXTURE

SCREW

MAIN MIXTURE

SCREW

SERIES III, IV

IDLE MIXTURE

SCREW

MAIN MIXTURE

SCREW

IDLE MIXTURE

SCREW

MAIN MIXTURE SCREW

F-3

DIAPHRAGM

"F"

DESIGNATION

Summary of Contents for AH520 -

Page 67: ...64...