16

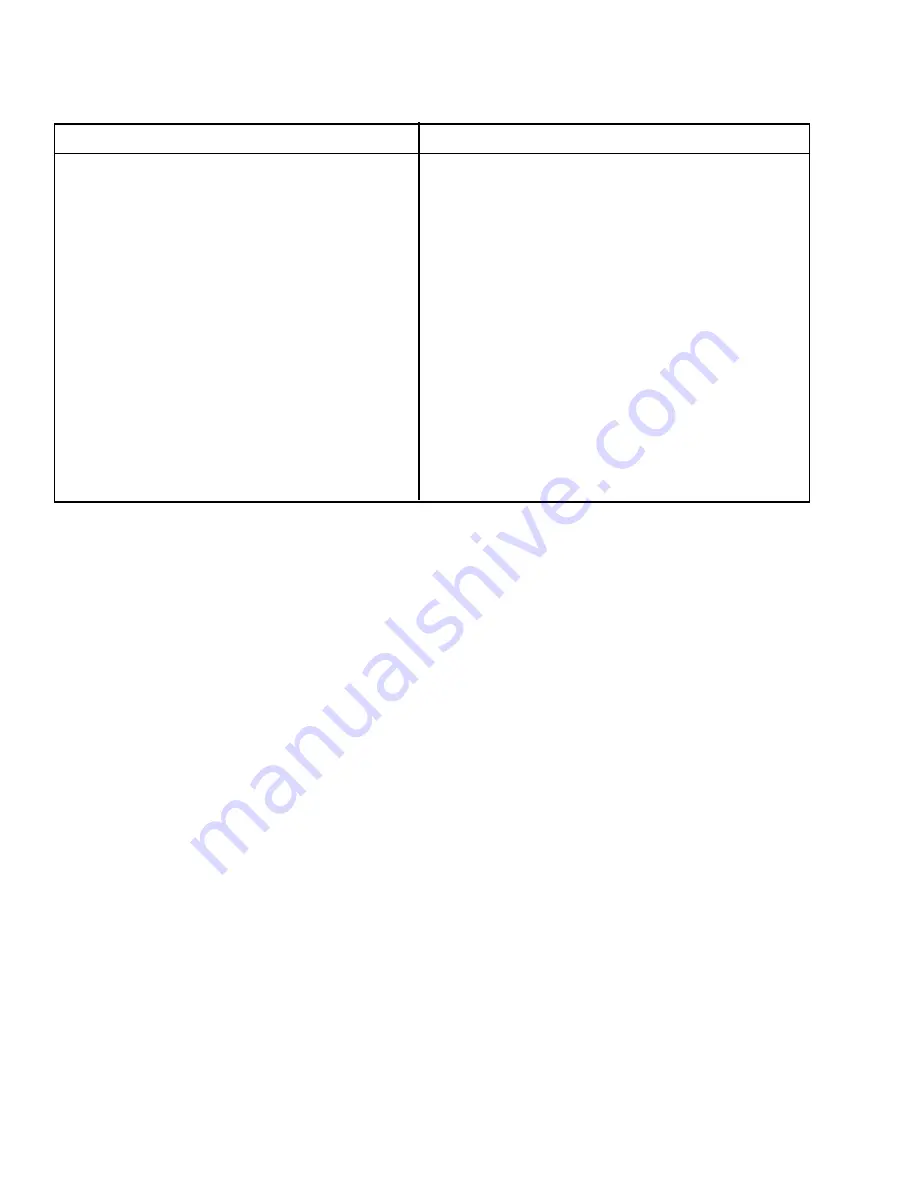

TROUBLESHOOTING CARBURETION

POINTS TO CHECK FOR CARBURETOR MALFUNCTION

TROUBLE

CORRECTIONS

Carburetor out of adjustment ...............................

3-4-11-12-13-15-20

Engine will not start .............................................

1-2-3-4-5-6-8-9-10-11-12-14-15-16-17-19-21-24-25

Engine will not accelerate ...................................

2-3-4-5-11-12-19-24

Engine hunts (at idle or high speed) ..................

3-4-8-9-10-11-12-14-20-21-24-26-27

Engine will not idle ...............................................

3-4-8-9-10-11-12-13-14-18-20-21-22-24-25-26-27

Engine lacks power at high speed .....................

2-3-4-6-8-10-11-12-15-18-19-20-21-24-25-26

Carburetor floods .................................................

4-7-17-21-22-25-26

Carburetor leaks ..................................................

4-6-7-10-17-18-23-24-25

Engine overspeeds ..............................................

8-9-11-14-15-18-20

Idle speed is excessive .......................................

8-9-13-14-15-18-20-25-26-27

Choke does not open fully ..................................

8-9-14-15

Engine starves for fuel at high speed (leans out)

1-3-4-5-6-10-11-15-16-17-18-19-21-25-26

Carburetor runs rich with main adjustment .........

7-8-9-11-14-17-18-19-21-25-26

needle shut off

Performance unsatisfactory after being serviced1-2-3-4-5-6-7-8-9-10-11-12-14-15-16-17-18-19-20-

21-24-25-26

16. Clean carburetor after removing all non-metallic

parts that are serviceable. Trace all passages.

17. Check inlet needle and seat for condition and

proper installation.

18. Check sealing of welch plugs, cups, plugs and

gaskets.

19. Check fuel pump operation pump element, inner

and outer one way valves.

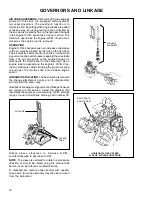

20. Adjust governor linkage.

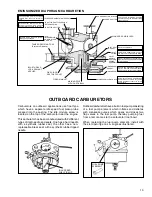

FLOAT CARBURETOR CHECKS

21. Adjust float setting.

22. Check float shaft for wear and float for leaks or

dents.

23. Check seal for fuel drain or bowl gasket.

24. Is carburetor operating at excessive angle?

CHECKS FOR DIAPHRAGM

25. Check diaphragm for cracks or distortion and check

nylon check ball for function.

26. Check sequence of gasket and diaphragm for the

particular carburetor being repaired.

27. Check spring tension on idle governor (if present).

1. Open fuel shut off valve at fuel tank. Fill tank

with fresh clean fuel.

2. Check ignition, spark plug and compression.

3. Clean air cleaner service as required.

4. Dirt or restriction in fuel system clean tank and

fuel strainers, check for kinks or sharp bends.

5. Check for stale fuel or water in fuel. Fill with fresh

fuel/oil mixture of correct ratio.

6. Examine fuel line and pick-up for sealing at fittings.

7. Check and clean atmospheric vent holes.

8. Examine throttle and choke shafts for binding or

excessive play remove all dirt or paint, replace

shaft.

9. Examine throttle and choke return springs for

operation.

10. Examine idle and main mixture adjustment screws

and O rings for cracks or damage.

11. Adjust main mixture adjustment screw. Some models

require finger tight adjustment. Check to see that

it is the correct screw.

12. Adjust idle mixture adjustment screw. Check to

see that it is the correct screw.

13. Adjust idle speed screw.

14. Check position of choke and throttle plates.

15. Adjust control cable or linkage to assure full choke

and carburetor control.

Summary of Contents for AH520 -

Page 67: ...64...