18

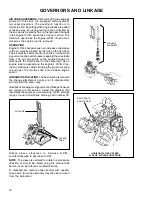

AIR VANE GOVERNORS.

All Tecumseh 2 cycle engines

covered in this book are equipped with pneumatic

(air vane) governors. The governor's function is to

maintain a R.P.M. setting when engine loads are added

or taken away. Air vane governors are controlled by

the air velocity created by fins on the flywheel. Changes

in the engine R.P.M. cause the air vane to move. The

throttle is opened as the engine R.P.M. drops and is

closed as the engine load is removed.

OPERATION

Engine R.P.M. changes cause an increase or decrease

in the air velocity created by the fins on the flywheel.

The air velocity exerts pressure on the air vane while

a governor spring exerts pressure against the air velocity

force. The air vane pivots on the engine flange or is

attached to the throttle shaft of the carburetor. As an

engine load is applied and the engine's R.P.M drop,

the air velocity also drops, allowing the governor spring

to pull open the throttle shaft and increase engine

speed.

LINKAGE INSTALLATION.

The best method is to record

the linkage attachment points prior to disassembly

and reinstall the same way.

Illustrations showing most governor and linkage hookups

are pictured in this section. Select the diagram that

resembles the engine you are servicing. R.P.M. settings

may be found in microfiche catalog, card number 30.

GOVERNORS AND LINKAGE

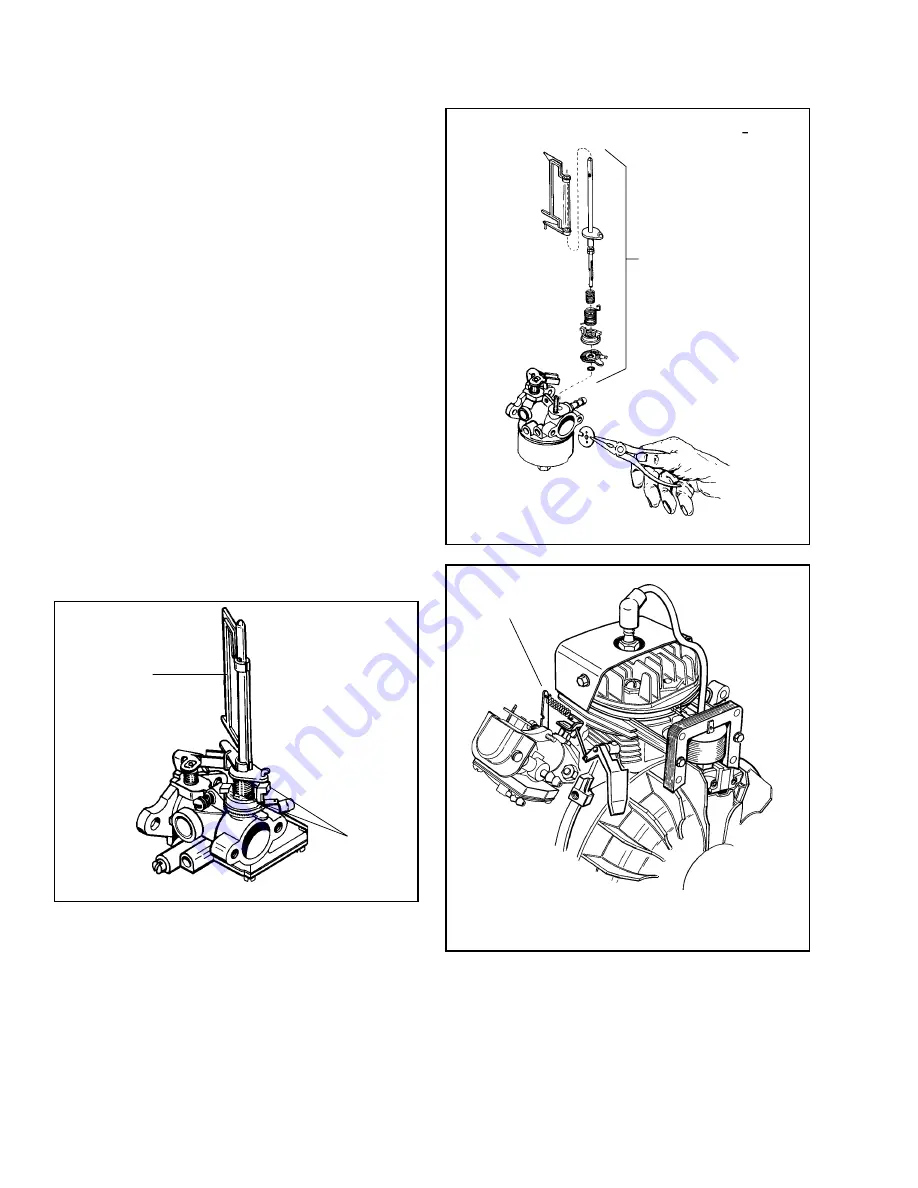

AIR VANE

SLEEVE

TABS

Rotate sleeve clockwise to increase R.P.M.;

counterclockwise to decrease R.P.M.

NOTE:

The sleeve is serrated to rotate in a clockwise

direction and must be raised using the sleeve tabs

before it can be rotated counterclockwise.

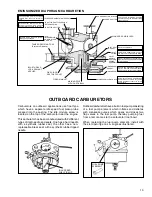

To disassemble, remove choke shutter with needle-

nose pliers; the vane assembly may then be removed

from the carburetor.

AIR VANE

ASSEMBLY

BEND TAB TO

ADJUST RPM

HORIZONTAL FIXED SPEED

PLASTIC AIR VANE GOVERNOR

Summary of Contents for AH520 -

Page 67: ...64...