30

INSIDE EDGE

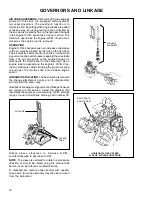

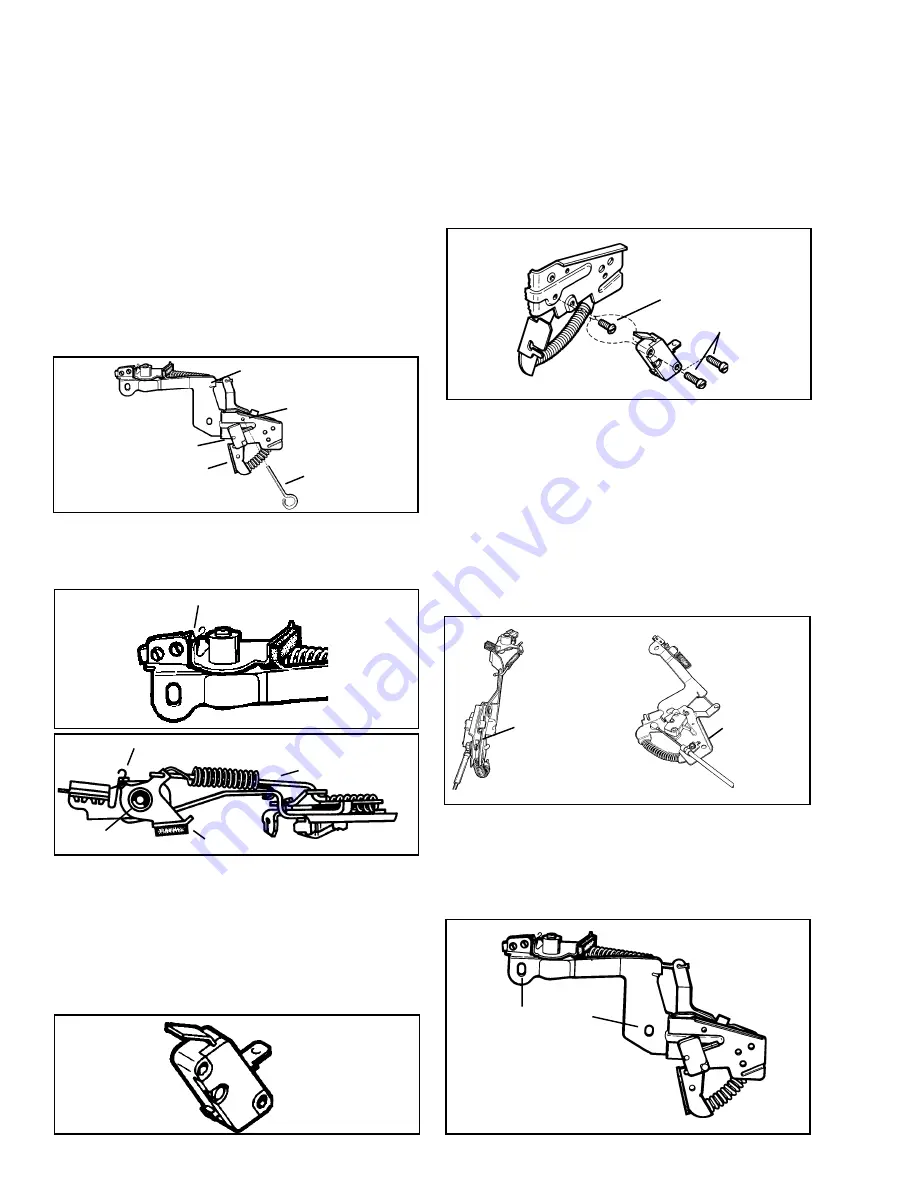

To relieve the brake pressure on the flywheel, compress

the spring by moving the lever toward the spark plug,

when the hole in the lever aligns with the hole in the

bracket, secure the lever with alignment tool 670298

then remove the flywheel (diag. 7). Remove the alignment

tool. Release the spring tension by unhooking the short

end of the spring from bracket with a pliers. Remove

the E clip from the brake pad shaft. Slide the pad

lever from the shaft and unhook the link. Inspect the

brake pad for dirt, oil or grease contamination. If the

pad is contaminated, or if there is less than .060" (1.524

mm) of brake pad material at the pad's thinnest point,

replacement is necessary. The brake pad is bonded

to the brake lever and must be replaced as an assembly.

Rehook the link, install the brake lever and pad assembly,

install the "E" clip, rehook the short end of the spring

and continue to reassemble the brake system in the

reverse order of disassembly.

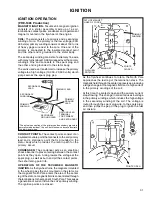

IGNITION GROUND OUT TERMINAL

Inspect the ignition kill switch grounding clip for proper

alignment and contact with the brake arm. Insure that

all electrical connections are clean and secure.

SHORT END OF SPRING

SWITCH

LEVER

670298

ALIGN HOLES

GROUNDING CLIP

"E" CLIP

GROUNDING CLIP POSITION

LINKAGE

BRAKE PAD

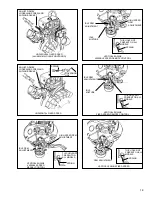

To replace the interlock switch, carefully grind the

heads off of the rivets that fasten the interlock switch

to the brake bracket. Remove the rivets from the back

side of brake bracket. Use the self-tapping screw

supplied with the new switch to make threads in the

bracket. Install the interlock switch onto the brake

bracket in the proper position and secure the switch

to the brake bracket with the machine screws supplied.

Be careful not to overtighten the screws as switch

breakage can occur.

CONTROL CABLE

INSIDE EDGE

If replacing the cable conduit screw with a screw other

than a service part replacement, be certain that the

screw length is not too long as to prevent free travel

of the lever. Make sure the button on the starter interlock

switch is completely depressed when the control is

fully applied. The cable must provide enough travel

so the brake will contact the flywheel. Some slack

should exist in the cable adjustment to compensate

for brake pad wear.

MACHINE

SCREWS

SELF TAPPING

SCREW

When installing a inside edge brake bracket assembly,

be sure the slotted holes in the brake bracket are all

the way down on the fasteners. This will properly align

the brake bracket to the flywheel brake surface.

SCREW END MUST

NOT BLOCK LEVER

ACTION

CABLE CLAMP

SCREW

STARTER INTERLOCK SWITCH

The engine / blade control must close the interlock

switch before the starter can be engaged. To check

the interlock switch, use an ohmmeter or continuity

light to perform a continuity check. Continuity should

exist between the two terminals when the interlock

switch button is completely depressed. No continuity

should exist when the button is released. If the switch

fails replace the switch.

MOUNTING HOLES

Ô

Ô

MECHANISM FULL DOWN

BEFORE SCREWS TORQUED

Summary of Contents for AH520 -

Page 67: ...64...