33

IGNITION SERVICE

SPARK PLUG SERVICE.

Spark plugs should be cleaned

and adjusted periodically. Check point gap with wire

feeler gauge (.030" - .762 mm) and adjust gap. Replace

if points are pitted and burned or the porcelain is cracked.

Refer to Master Parts Manual or Micro-Fiche for correct

replacement number.

If spark plug fouls frequently, check for the following

conditions:

1. Carburetor set too rich.

2. Choke not opening fully.

3. Poor grade gasoline.

4. Clogged exhaust system.

5. Incorrect spark plug.

6. Improper oil fuel ratio.

7. Inconsistent spark.

NOTE:

Ensure cleaned spark plugs are free of

all foreign material before installation.

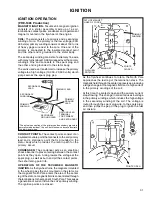

FLYWHEEL REMOVAL AND SERVICE.

To remove

flywheel, use a strap wrench Part No. 670305 to hold

the flywheel and remove the nut by turning it in the

direction opposite of crankshaft rotation.

STRAP WRENCH

670305

FLYWHEEL PULLER

670306

NOTE:

A KNOCK-OFF TOOL IS NOT RECOMMENDED

FOR ENGINES WITH A BALL BEARING ON THE

MAGNETO END OF THE CRANKSHAFT.

NOTE:

If a knock-off tool is used, the pounding may

cause the ball bearing to dislodge from the shroud

base and force the lower thrust face of the crankshaft

against the cylinder thrust face. TO CORRECT THIS

CONDITION RAP SHARPLY WITH RAWHIDE MALLET

ON THE P.T.O. END TO PROVIDE CLEARANCE

BETWEEN CRANKSHAFT AND CYLINDER THRUST

FACE.

BALL BEARING

MUST HAVE

CLEARANCE

NOTE:

Do not attempt to remove flywheel using a

jaw type pullers on the outer diameter of the flywheel

or flywheel breakage will occur.

On engines with cored holes (not tapped) use flywheel

puller part No. 670306.

If the flywheel is difficult to remove from the crankshaft

because of rust, etc., the use of a propane torch can

be helpful. Heat the area immediately outside of the

crankshaft. The aluminum alloy in the flywheel should

expand enough to break the seal away from the steel

crankshaft.

FLYWHEEL MAGNETS.

The magnets in the flywheel

rarely lose their magnetic strength. If magnets are

suspected to be faulty, place the flywheel upside down

on a wooden surface. Hold a screwdriver by the extreme

end of handle with the point down. Move the blade to

within 3/4 inch of magnets. The magnets should attract

the screwdriver blade against the magnet.

3/4" (19

mm

)

MAGNETS

SCREWDRIVER LENGTH

APPROXIMATELY

6" (15.24 cm)

Summary of Contents for AH520 -

Page 67: ...64...