34

FLYWHEEL KEYS.

The flywheel key locates the flywheel

to the crankshaft in the proper position. If a flywheel

key is sheared, or partially sheared, the engine will

not start or may be difficult to start.

FLYWHEEL TORQUE.

Torque flywheel to the proper

specification. See the tables in specification section

for the proper torque setting.

Loose lawn mower blades and adapters can contribute

to sheared keys.

REPLACING MAGNETO BREAKER POINTS.

Remove

the nut holding the electrical leads to the screw on

the movable portion of the breaker points.

Remove the screw from the stationary breaker point

and remove point set. Reinstall the new breaker point

set into position and adjust the point gap according

to the specifications. Points must be adjusted, when

the rubbing block of the points is on the highest spot

on the breaker cam.

Clean points by putting lint-free paper between them

and sliding it back and forth. Then open points and

remove paper and any paper fiber remaining between

the point set. Any oil, fingerprints or contamination

will cause the points to burn prematurely.

CONDENSER CHECK.

Check condenser on a good

quality tester, following the test equipment

manufacturers instructions to check capacity and

resistance. Replace condenser if condition is

questionable.

IGNITION COIL.

Inspect the coil for cracks in insulation

or other damage. Make sure electrical leads are intact,

especially where they enter the coil.

Check operation of the coil using an approved tester

following the instructions furnished with the test unit.

If laminations are distorted or damaged, replace. Some

coils are permanently attached to the laminations and

must be serviced as an assembly.

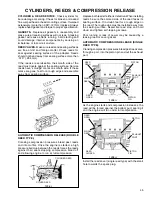

IGNITION TIMING.

Begin procedure by setting the

point gap. This is done by rotating the crankshaft until

the point arm is resting on the high side of the ignition

cam. Set the point gap by loosening the screw on

the movable point, and insert a feeler gauge per

specification. Tighten the screw then recheck the gap.

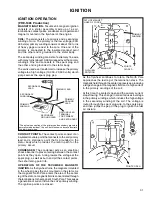

NON-COMPLIANCE ENGINE

COMPLIANCE ENGINE

KEY

FLYWHEEL

SLEEVE

NOTE:

Use the Tecumseh Master Parts Manual to

determine correct key for the application.

ADAPTER KEY TO FLYWHEEL ASSEMBLY.

When

an adapter is used, place the adapter with its raised

key area in the flywheel keyway before putting the

flywheel on the engine.

STEEL

ALUMINUM

ALLOY

GOLD

SOLID STATE

IGNITION

CRANKSHAFT

TIMING

TABS

FLYWHEEL SLEEVE.

Some engines utilize a sleeve

between the crankshaft and flywheel which acts as a

flywheel key. If this sleeve becomes sheared or

damaged, replace. The flywheel sleeve is pressed

into the crankshaft opening in the flywheel, and should

be flush or slightly below flush from the inside surface

of flywheel before in stalling on crankshaft.

For engines equipped with brake system, a new key

and flywheel are shown. Torque procedures are the

same.

CRANKSHAFT

CAM

ARM

POINTS

PIVOT

SLEEVE TO BE

PRESSED IN

FLUSH

WITH HUB

Summary of Contents for AH520 -

Page 67: ...64...