36

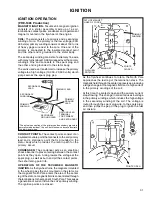

FIXED TIME SYSTEM (External Coil).

This system

has the contact points and condenser mounted under

the flywheel with the laminations and coil mounted

outside the flywheel. This system is identified by the

square hole in the stator, the round configuration of

the coil, and a stepped flywheel key.

Begin the timing procedure, torque down the stator

bolts to secure the stator in place. Next rotate the

crankshaft until the point arm is resting on the high

side of the ignition cam. Set the point gap at to the

proper specification by loosening the screw on the

movable point, and inserting a feeler gauge between

the contact points. Tighten the screw on the movable

point and then recheck the point gap. Be sure to clean

the contact points with lint free paper.

Reinstall the proper flywheel key, flywheel, washer,

and torque down the flywheel nut to specification.

Reinstall the external coil, but do not tighten down

the mounting screws.

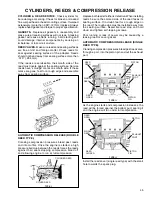

SOLID STATE (CDI).

This is an all electronic ignition

system with the components sealed in a module and

located outside the flywheel.

A Solid State module can be identified by its square

configuration, which will identify the need for the proper

flywheel key or sleeve.

STEPPED KEY

STEPPED

END

TOWARD

ENGINE

FLYWHEEL

SLEEVE

ROUND COIL

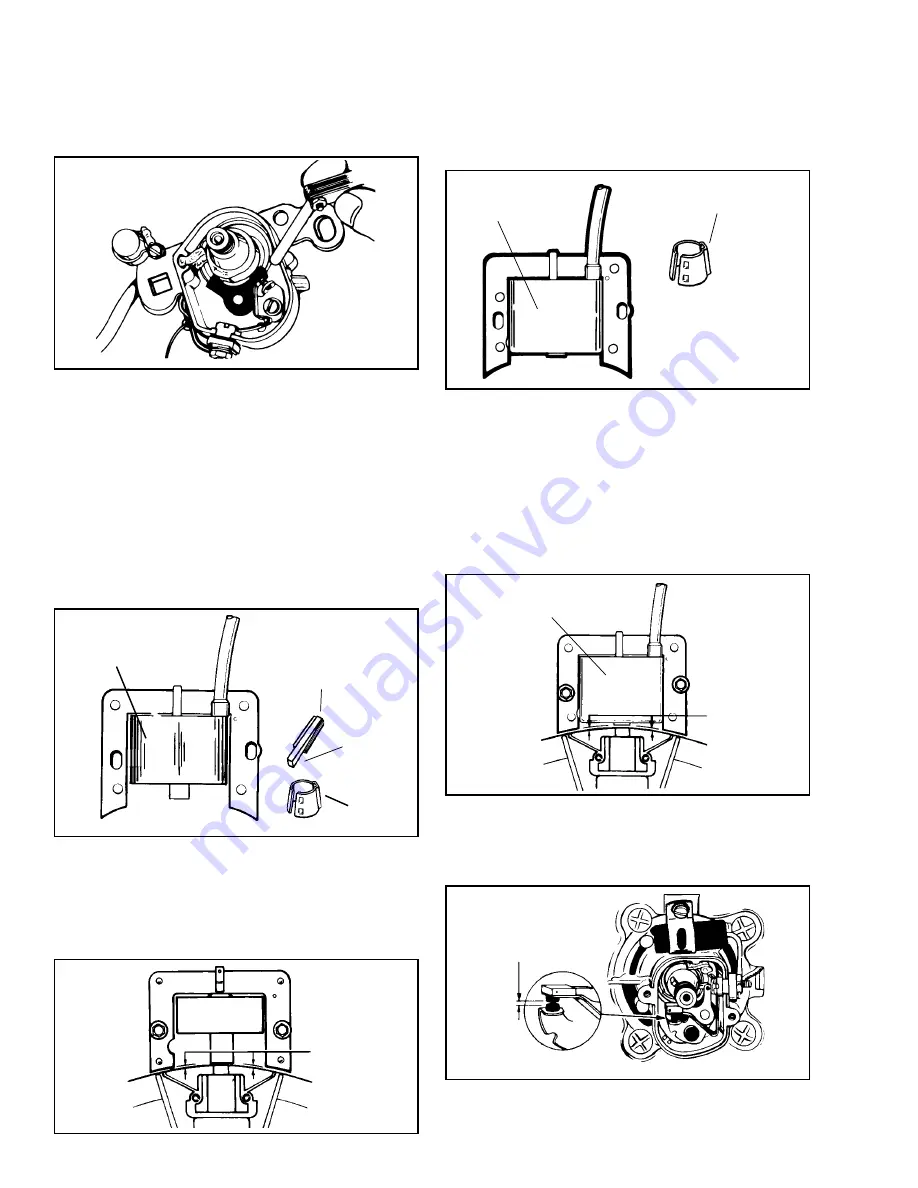

Timing this system consists of having the proper .0125"

(.317 mm) air gap gauge, (Part No. 670297) between

the magnets and laminations and torque down the

mounting screws to specification. Remove air gap

gauge and rotate flywheel to check for any possible

striking points. If none are found, the air gap is set

correctly and the timing procedure is completed.

.0125”

(.317 mm)

The proper air gap setting between the flywheel magnets

and the laminations on both the fixed time and CDI

systems is .0125'. Place .0125' gauge, part No. 670297

between the magnets and laminations and torque down

mounting screws to specification. Recheck gap setting

to make certain there is proper clearance between

the magnets and laminations.

NOTE:

Due to variations

between pole shoes, air gap may vary from .005/.020'

when flywheel is rotated. There is no further timing

adjustment on external lamination systems.

FLYWHEEL SLEEVE

SQUARE MODULE

SQUARE MODULE

.0125"

SET GAP

PER SPECIFICATION

OTHER IGNITION SYSTEMS.

Ignition systems on

engines with a non-adjustable stator, set the points

per specification. If the coil is located under the flywheel,

no other timing is required.

Summary of Contents for AH520 -

Page 67: ...64...