3

Add stabilizer to fuel in fuel tank or storage container.

Always follow mix ratio found on stabilizer container.

Run engine at least 10 minutes after adding stabilizer

to allow it to reach carburetor.

If gasohol has been used, complete preceding

instructions and then add a small amount, one

pint or less, of unleaded regular automotive gasoline

properly mixed with the specified lubricating oil

and run the engine until the fuel tank is empty

and the engine stops due to lack of fuel.

2. Pull starter handle slowly until resistance is felt

due to compression pressure, then stop. Release

starter tension slowly to prevent engine from

reversing due to compression pressure. This position

will close both the intake and exhaust ports to

prevent corrosion of the piston and the cylinder

bore.

3. Clean unit by removing any dirt from exterior of

the engine and equipment.

TUNE-UP PROCEDURE.

The following is a minor tune-

up procedure. Repair procedures for this engine and

its components are listed in this manual if the engine

does not perform to satisfaction after tune-up is

performed.

CAUTION:

Remove spark plug wire before doing

any service work on engine.

1. Service or replace air cleaner as necessary.

NOTE:

Snow King

®

engines do not use an air filter

due to the clean operating environment and to

prevent filter freeze-up.

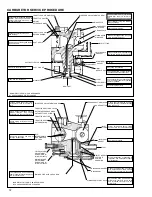

2. Remove blower housing, clean all dirt, grass or

debris from air intake screen, cylinder cooling fins,

and carburetor governor levers and linkage.

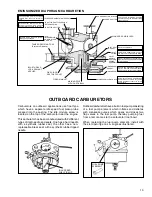

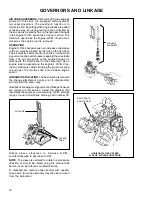

3. Remove carburetor, clean and install a carburetor

kit, make adjustment presets where needed. Presets

are found in the carburetor section of this manual.

Make sure fuel tank, fuel filters and fuel lines are

clean. Reinstall carburetor, replacing any worn

or damaged governor springs or linkage. Make

proper governor adjustment. Adjustments are found

in the manual under governor linkage and

adjustment and engine reassembly.

4. Replace the spark plug with a correct equivalent.

5. Make sure all ignition wires are properly routed,

so they will not rub on flywheel. Inspect all ignition

wires for abrasion or damage. Remove flywheel

and check flywheel key, reinstall flywheel, torque

flywheel nut to specifications. Set air gap between

solid state module and flywheel at .0125'. Air gap

gauge, part no. 670297 may be used.

6. The engine must be firmly mounted to the associated

equipment. On rotary lawnmowers, make sure blade

is properly balanced and correctly torqued. See

disassembly section for flywheel removal and air

gap setting procedure.

7. Make sure all remote linkage is properly adjusted

for operation.

8. Fill tank with the proper fuel/oil mix.

9. Start the engine, allow it to warm up 5 minutes,

then adjust carburetor and engine R.P.M. according

to Tecumsehs recommendations.

Snow King

®

engines should be run in outdoor

temperatures for engine adjustments.

NOTE:

Emissionized engines have non-adjustable

carburetors in compliance with CARB (California Air

Resource Board) and U.S. EPA (United States

Environmental Protection Agency). These engines can

not be modified without specific authorization.

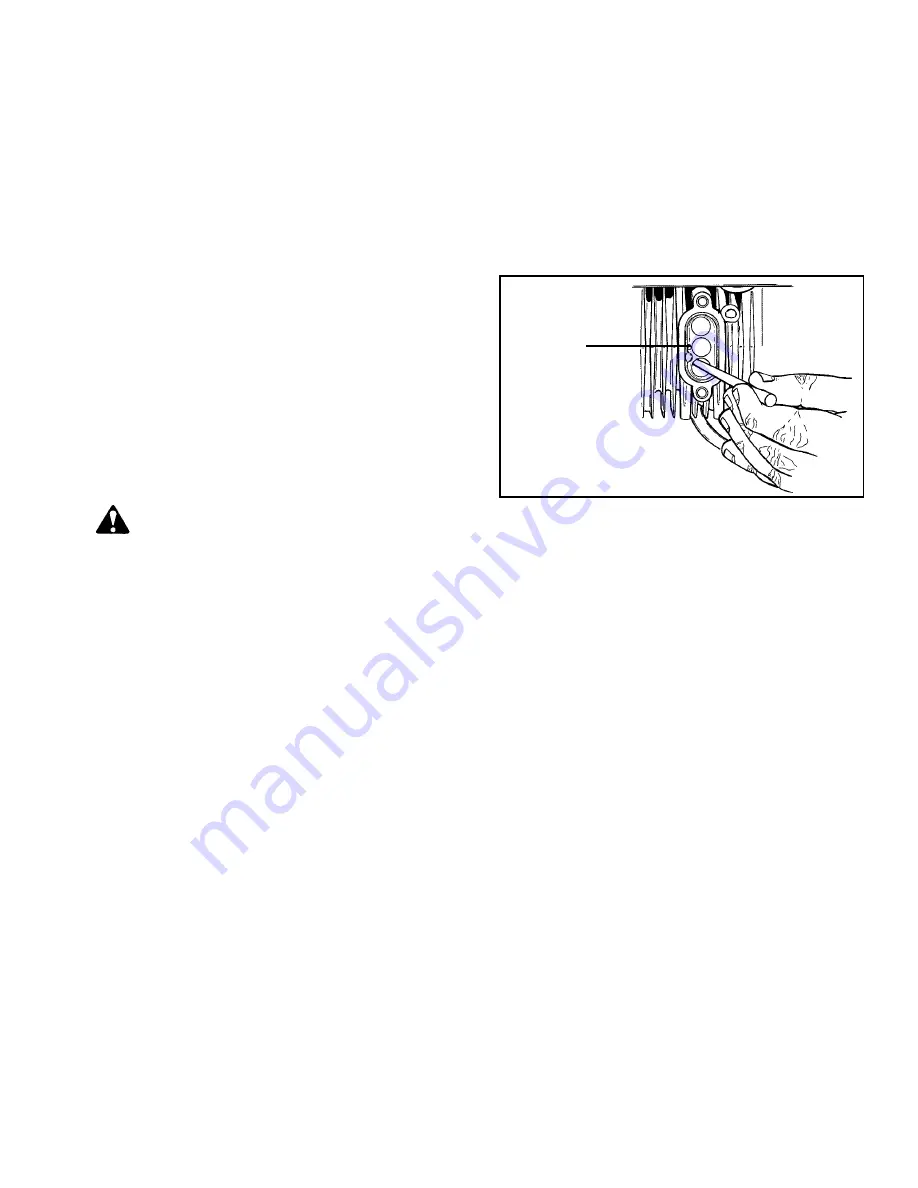

EXHAUST PORT CLEANING.

The exhaust ports should

be cleaned after each seventy-five (75) to one hundred

(100) hours of use.

Before cleaning the ports place the piston in the Bottom

Dead Center position. Then clean the ports using a

pointed 3/8' diameter wooden dowel or similar tool.

Be sure not to scratch the port area. Also remember

to remove all the loose carbon particles from the engine.

NOTE:

When cleaning the exhaust ports, check and

clean the compression release passage.

COMPRESSION

RELEASE

PASSAGE

Summary of Contents for AH520 -

Page 67: ...64...