7

WARNING!

To avoid electric shock, electrocution and terminal venting with igni-

tion, do not energize a compressor that has a ground fault. Mark and red tag the

compressor to indicate that there is a ground fault. Do not reconnect the power

leads. Tape and insulate each power lead separately. Proceed to Step 2. Do not

replace the compressor or energize the system before performing Step 2.

Step 2: Check for Water in the System

Once the compressor is cool to the touch, open the system process valve slightly to see if

any water comes out of the system.

WARNING!

Opening the system process valve while

the compressor is hot can cause severe burns from steam coming out of the valve.

If ANY water comes out of the process valve, the entire system

must

be replaced. See

"replacing a Single-wall Water-utilizing System” below.

If water does not come out of the process valve, there is still a possibility that some water

has leaked into the refrigerant side of the system. To address this possibility, determine if

the system has a history of losing refrigerant charge without a leak being found or repaired.

If you find ANY indication of a history of losing refrigerant charge without detection of a

leak, this is a sign that refrigerant has leaked in the water inside the heat exchanger. The

entire system

must

be replaced. See “Replacing a Single-wall Water-utilizing System” on

page 33.

If you do not find any indication of a history of loss of charge without detection of a leak,

you still need to install:

»

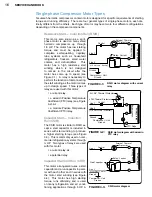

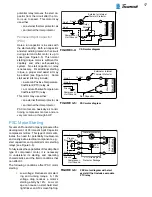

a high-pressure cut-out which interrupts power to ALL leads to the compressor,

or

»

an external pressure relief valve.

Also, if you found a ground fault in the compressor in Step 1, replace the compressor be-

fore applying power to the system.

Start Capacitor Overheating

An overheated start capacitor can burst and spray or splatter hot material that can cause burns.

Applying voltage to a start capacitor for more than a few seconds can cause the capacitor to

overheat.

Check capacitors with a capacitance meter, and never check a capacitor with the power on.

System Evacuation

Never use a compressor to evacuate a system. Instead, use a high-vacuum pump specifically

designed for that purpose.

Never start the compressor while it is under deep vacuum. Always break a vacuum with a mini-

mum 2 psig refrigerant charge before energizing the compressor.

The compressor is cooled primarily by the flow of refrigerant. Running a system that is low on

charge will reduce the life of the comperssor.

Failure to follow these instructions can damage the hermetic terminal. As always, to avoid seri-

ous injury or death from terminal venting with ignition, never energize the compressor unless the

protective terminal cover is securely fastened.

Summary of Contents for AH5540E

Page 1: ...Hermetic Compressor Service Handbook Wholesale Distribution North America...

Page 2: ......

Page 3: ...Hermetic Compressor Service Handbook Ann Arbor MI 48108 REV 3 11...

Page 4: ......

Page 8: ......

Page 9: ...Chapter 1 General Service Safety Precautions...

Page 16: ......

Page 17: ...Chapter 2 Model and Application...

Page 22: ......

Page 23: ...Chapter 3 Compressor Motor and Component...

Page 36: ......

Page 37: ...Chapter 4 Servicing...

Page 38: ...30 SERVICE HANDBOOK...

Page 79: ...71...

Page 80: ......

Page 81: ...Chapter 5 Installation and Replacement...

Page 96: ......

Page 97: ...Liquid refrigerant migration to compressor FIGURE 6 1 Chapter 6 Operation...

Page 108: ......

Page 109: ...Appendix...

Page 113: ...105 Reciprocating Compressor FIGURE A 2 Internal view of typical air conditioning compressor...

Page 118: ...110 SERVICE HANDBOOK Notes...

Page 119: ......