21

Compressor Motor Starting Relays

A hermetic motor starting relay is an automatic switching device to disconnect the motor start

capacitor and/or start winding after the motor has reached running speed.

Never select a replacement relay solely by horsepower or other generalized rating. Select the cor-

rect relay from the Tecumseh Electrical Service Parts Guide Book.

There are two types of motor starting relays used in refrigeration and air conditioning applications:

the current responsive type and the potential (voltage) responsive type.

Current Type Relay

When power is applied to a compressor motor, the relay solenoid coil attracts the relay

armature upward causing bridging contact and stationary contact to engage. This ener-

gizes the motor start winding. When the compressor motor attains running speed, the

motor main winding current is such that the relay solenoid coil de-energizes allowing the

relay contacts to drop open thereby disconnecting motor start winding. The relay must

be mounted in true vertical position so armature and bridging contact will drop free when

relay solenoid is de-energized. See Figure 3-11.

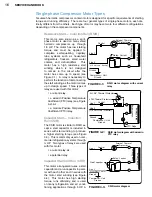

PTC Type Relay

PTC type relay is a solid state current sensitive relay. Certain ceramic materials have the

unique property of greatly increasing their resistance as they heat up from current passing

through them. A PTC solid state starting device is placed in series with the start winding

and normally has a very low resistance. Upon startup, as current starts to flow to the start

winding, the resistance rapidly rises to a very high value thus reducing the start winding

current to a trickle and effectively taking that winding out of operation. See Figure 3-12.

Usage is generally limited to domestic refrigeration and freezers. Because it takes 3 to 10

minutes to cool down between operating cycles, it is not feasible for short cycling com-

mercial applications.

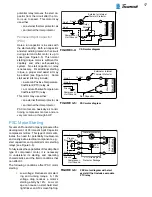

Potential Type Relay

Potential type relays are generally used with large commercial and air conditioning com-

pressors (capacitor start, capacitor run) to 5 HP. Relay contacts are normally closed. The

relay coil is wired across the start winding and senses voltage change. Starting winding

voltage increases with motor speed. As the voltage increases to the specific pickup value,

the armature pulls up, opening the relay contacts, de-energizing the start winding capaci-

tor. After switching, there is still sufficient voltage induced in the start winding to keep the

relay coil energized and the relay starting contacts open. When power is shut off to the

motor, the voltage drops to zero, the coil is de-energized, and the start contacts reset. See

Figure 3-13.

When changing a compressor relay, care should be taken to install the replacement in the

same position as the original. Table 3-4 lists useful information regarding starting relays.

FIGURE 3-12:

PTC Type Relay

FIGURE 3-13:

Potential Type Relay

FIGURE 3-11:

Current Type Relay

Summary of Contents for AH5540E

Page 1: ...Hermetic Compressor Service Handbook Wholesale Distribution North America...

Page 2: ......

Page 3: ...Hermetic Compressor Service Handbook Ann Arbor MI 48108 REV 3 11...

Page 4: ......

Page 8: ......

Page 9: ...Chapter 1 General Service Safety Precautions...

Page 16: ......

Page 17: ...Chapter 2 Model and Application...

Page 22: ......

Page 23: ...Chapter 3 Compressor Motor and Component...

Page 36: ......

Page 37: ...Chapter 4 Servicing...

Page 38: ...30 SERVICE HANDBOOK...

Page 79: ...71...

Page 80: ......

Page 81: ...Chapter 5 Installation and Replacement...

Page 96: ......

Page 97: ...Liquid refrigerant migration to compressor FIGURE 6 1 Chapter 6 Operation...

Page 108: ......

Page 109: ...Appendix...

Page 113: ...105 Reciprocating Compressor FIGURE A 2 Internal view of typical air conditioning compressor...

Page 118: ...110 SERVICE HANDBOOK Notes...

Page 119: ......