81

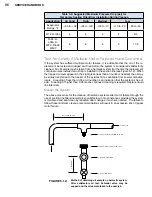

Cond. Unit

CAP

ACITY

(Btu/h)

Line Size, T

ype L Copper OD (in)

SUCTION LINE SIZE OD (in)

Line Length, Equivalent F

eet

Ve

lo

ci

ty

= 1500

fpm*

LIQUID LINE SIZE OD (in)

Line Length, Equivalent F

eet

Ve

lo

ci

ty

= 100

fpm*

DISCHARGE LINE SIZE OD (in)

Line Length, Equivalent F

eet

Ve

lo

ci

ty

= 1500

fpm*

10

25

50

100

10

25

50

100

10

25

50

100

1,000

1/4

5/16

5/16

3/8

1/4

3/16

3/16

3/16

3/16

~

3/16

3/16

1/4

1/4

~

2,000

5/16

3/8

3/8

1/2

5/16

3/16

3/16

1/4

1/4

3/16

1/4

1/4

1/4

5/16

3/16

3,000

3/8

3/8

1/2

1/2

3/8

3/16

1/4

1/4

1/4

1/4

1/4

1/4

5/16

5/16

3/16

4,000

3/8

1/2

1/2

5/8

3/8

3/16

1/4

1/4

5/16

1/4

1/4

5/16

5/16

3/8

1/4

6,000

1/2

1/2

5/8

5/8

1/2

1/4

1/4

5/16

5/16

5/16

5/16

5/16

3/8

1/2

5/16

8,000

1/2

5/8

5/8

3/4

1/2

1/4

5/16

5/16

3/8

5/16

5/16

3/8

3/8

1/2

5/16

10,000

1/2

5/8

3/4

3/4

5/8

1/4

5/16

5/16

3/8

3/8

3/8

3/8

1/2

1/2

3/8

12,000

1/2

5/8

3/4

7/8

5/8

1/4

5/16

3/8

3/8

3/8

3/8

1/2

1/2

1/2

3/8

18,000

5/8

3/4

7/8

1 1/8

3/4

5/16

3/8

3/8

1/2

1/2

1/2

1/2

1/2

5/8

1/2

24,000

3/4

7/8

7/8

1 1/8

7/8

5/16

3/8

1/2

1/2

1/2

1/2

1/2

5/8

5/8

1/2

30,000

3/4

7/8

1 1/8

1 1/8

7/8

3/8

1/2

1/2

1/2

5/8

1/2

5/8

5/8

3/4

1/2

36,000

3/4

7/8

1 1/8

1 3/8

1 1/8

3/8

1/2

1/2

5/8

5/8

1/2

5/8

3/4

3/4

5/8

48,000

7/8

1 1/8

1 1/8

1 3/8

1 1/8

1/2

1/2

5/8

5/8

3/4

5/8

3/4

3/4

7/8

3/4

60,000

1 1/8

1 1/8

1 3/8

1 3/8

1 3/8

1/2

1/2

5/8

5/8

7/8

5/8

3/4

7/8

1 1/8

7/8

Table 5-8: R-404A Refrigerant Line Sizes, -10°F Evap T

emp, 40°F Suction V

apor T

emp, 105°F Condensing and Liquid T

emp

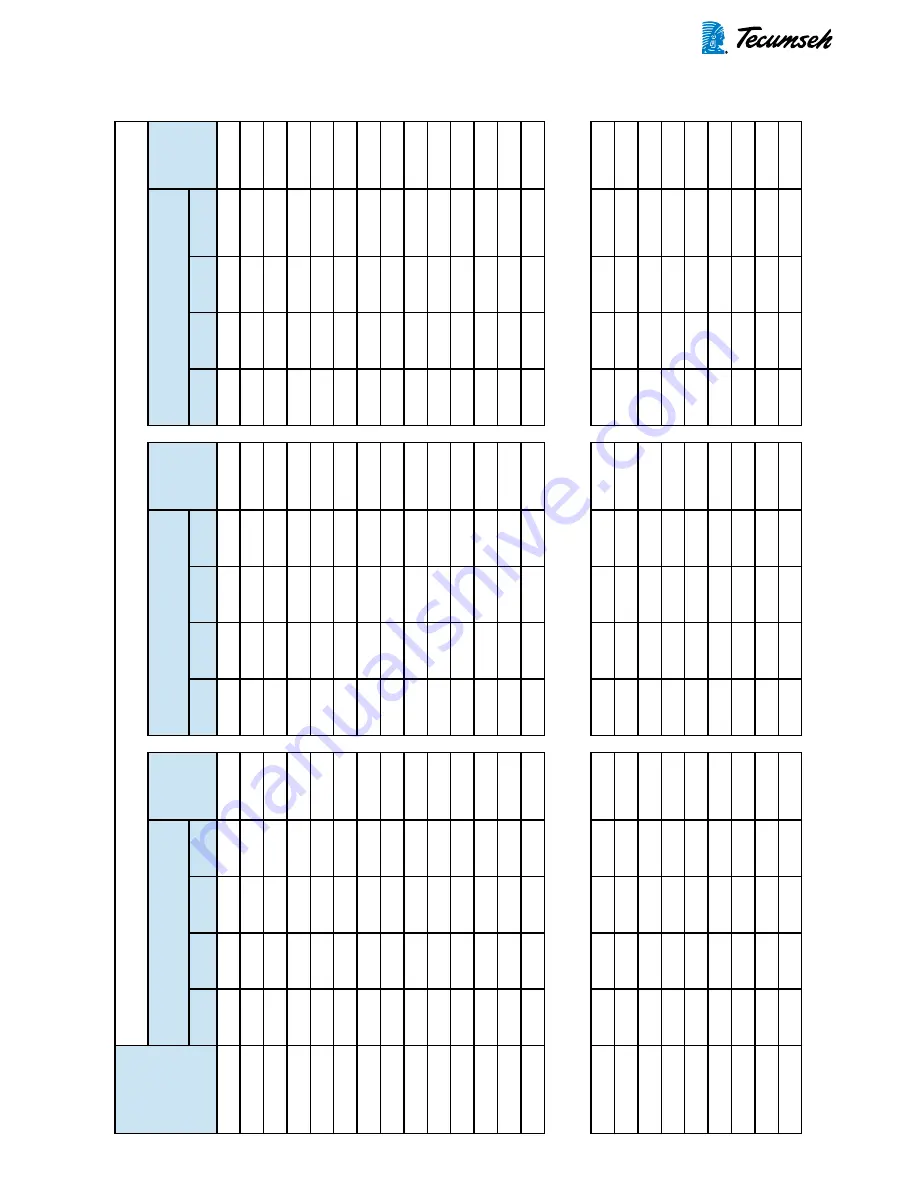

1,000

5/16

3/8

3/8

1/2

5/16

3/16

3/16

3/16

3/16

~

3/16

1/4

1/4

1/4

~

2,000

3/8

1/2

1/2

5/8

3/8

3/16

3/16

1/4

1/4

3/16

1/4

1/4

1/4

5/16

3/16

3,000

1/2

1/2

5/8

5/8

1/2

3/16

1/4

1/4

1/4

1/4

1/4

5/16

5/16

5/16

1/4

4,000

1/2

5/8

5/8

3/4

1/2

1/4

1/4

1/4

5/16

1/4

5/16

5/16

5/16

3/8

1/4

6,000

1/2

5/8

3/4

7/8

5/8

1/4

1/4

5/16

5/16

5/16

5/16

3/8

3/8

1/2

5/16

8,000

5/8

3/4

3/4

7/8

3/4

1/4

5/16

5/16

3/8

3/8

3/8

3/8

1/2

1/2

3/8

10,000

5/8

3/4

7/8

1 1/8

7/8

1/4

5/16

3/8

3/8

3/8

3/8

1/2

1/2

1/2

3/8

12,000

3/4

7/8

7/8

1 1/8

7/8

5/16

5/16

3/8

1/2

3/8

3/8

1/2

1/2

5/8

3/8

18,000

3/4

7/8

1 1/8

1 1/8

1 1/8

5/16

3/8

1/2

1/2

1/2

1/2

1/2

5/8

5/8

1/2

Table 5-7: R-404A Refrigerant Line Sizes, 20°F Evap T

emp, 40°F Suction V

apor T

emp, 105°F Condensing and Liquid T

emp

*

Largest

line

size

that

will

maintain

the

stated

refrigerant

velocity

.

Please

consult

industry

references

such

as

the

ASHRAE

Refrigeration

Handbook

for

additional

infor

-

mation regarding how to properly size suction and discharge line risers and condenser to receiver condensate lines.

Summary of Contents for AH5540E

Page 1: ...Hermetic Compressor Service Handbook Wholesale Distribution North America...

Page 2: ......

Page 3: ...Hermetic Compressor Service Handbook Ann Arbor MI 48108 REV 3 11...

Page 4: ......

Page 8: ......

Page 9: ...Chapter 1 General Service Safety Precautions...

Page 16: ......

Page 17: ...Chapter 2 Model and Application...

Page 22: ......

Page 23: ...Chapter 3 Compressor Motor and Component...

Page 36: ......

Page 37: ...Chapter 4 Servicing...

Page 38: ...30 SERVICE HANDBOOK...

Page 79: ...71...

Page 80: ......

Page 81: ...Chapter 5 Installation and Replacement...

Page 96: ......

Page 97: ...Liquid refrigerant migration to compressor FIGURE 6 1 Chapter 6 Operation...

Page 108: ......

Page 109: ...Appendix...

Page 113: ...105 Reciprocating Compressor FIGURE A 2 Internal view of typical air conditioning compressor...

Page 118: ...110 SERVICE HANDBOOK Notes...

Page 119: ......