84

SERVICE HANDBOOK

Determine Extent of System Contamination

Following the precautions in ”Refrigerants and Other Chemicals” and “Compressor

Removal” on page 4, remove the compressor.

Use the following guidelines to determine whether contamination, if any, is limited to the

compressor or extends to the system.

If the discharge line shows no evidence of contamination and the suction stub is clean

or has only light carbon deposits, then the contaminants are limited to the compressor

housing (Compressor Housing Contamination). A single installation of liquid and suction

line filter-driers should clean up the system.

If, however, the discharge line or the suction line shows evidence of contamination, the

compressor was running at the time of the motor failure and contaminants were pumped

throughout the system (System Contamination). If System Contamination has occurred,

several changes of the liquid and suction line filter-driers will be needed to cleanup the

system. In addition, the expansion device will need to be replaced. If the system is a heat

pump, the four way valve should be replaced.

Install Replacement Compressor and Components

1. Install the replacement compressor with new external electrical components (capacitors,

relay, overloads, etc., where applicable). Check the contacts of the starting control or

contactor.

2. Install an oversized liquid line filter-drier.

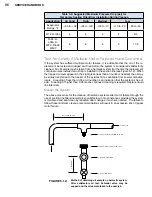

3. Install a generously sized suction line filter-drier immediately upstream of the

compressor. The filter-drier when permanently installed in a clean system or as initially

installed in a dirty system, must have a pressure drop not more than listed in Table 5-7.

Pressure taps must be supplied immediately before and after the suction filter-drier to

permit the pressure drop to be measured.

If a suction line accumulator is present and System Contamination has occurred, it

must be thoroughly flushed to remove any trapped sludge and thus prevent it from

plugging the oil return hole. The filter-drier should be installed upstream of the accu-

mulator and the compressor.

In the case of Compressor Housing Contamination, the filter-drier should be installed

between the compressor and the suction line accumulator.

Rubber refrigeration hoses are not satisfactory for temporarily hooking up the suction

line filter-drier to the system since the acid quickly breaks down the rubber and plastic.

4. Follow the precautions in “System Flushing, Purging, and Pressure Testing or Leaks”

on pages 4-5 to purge the system and pressure test for leaks.

Evacuate the System

Evacuate the system to less than 500 microns using a good vacuum pump (not a com-

pressor) and an accurate high vacuum gauge.

An alternate and more thorough method of evacuation known as "triple evacuation" is as

follows:

1. Evacuate the system to 1500 microns. Break vacuum with the serial label refrigerant or

an inert gas up to 2 psig. Leave vapor charge in system for a minimum of five minutes.

2. Repeat Step 1.

3. Evacuate system to 500 microns. Charge system with the specified kind and quantity

of refrigerant.

Summary of Contents for AH5540E

Page 1: ...Hermetic Compressor Service Handbook Wholesale Distribution North America...

Page 2: ......

Page 3: ...Hermetic Compressor Service Handbook Ann Arbor MI 48108 REV 3 11...

Page 4: ......

Page 8: ......

Page 9: ...Chapter 1 General Service Safety Precautions...

Page 16: ......

Page 17: ...Chapter 2 Model and Application...

Page 22: ......

Page 23: ...Chapter 3 Compressor Motor and Component...

Page 36: ......

Page 37: ...Chapter 4 Servicing...

Page 38: ...30 SERVICE HANDBOOK...

Page 79: ...71...

Page 80: ......

Page 81: ...Chapter 5 Installation and Replacement...

Page 96: ......

Page 97: ...Liquid refrigerant migration to compressor FIGURE 6 1 Chapter 6 Operation...

Page 108: ......

Page 109: ...Appendix...

Page 113: ...105 Reciprocating Compressor FIGURE A 2 Internal view of typical air conditioning compressor...

Page 118: ...110 SERVICE HANDBOOK Notes...

Page 119: ......