Model KT14000 power casing tong maintenance and operation manual

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

7

This is accomplished by leaving slack in the “jaw-pipe” engagement, and then quickly pulling the throttle

valve control lever allowing the tong to snap into its loaded or high torque conditions. This method,

although very affective in breaking out joints, highly stresses the gear train and very frequently causes gear

breakage. This method is also dangerous to operating personnel.

4.

Maintenance

It is suggested that a regular maintenance program be established, to assure dependable operation of the

TEDA Hydraulic power tong. The following recommendations concerning cleaning, lubrication, and

adjustments will enhance the life expectancy of the tong and assure safety to operating personnel.

4.1

Cleaning

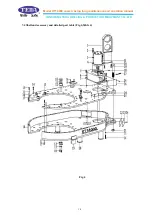

The centralizing roller(2) of the upper panel and open gear should be thoroughly cleaned with a good

petroleum base cleaning agent, after each job, prior to storage. One month later after usage of the new tong,

replace the hydraulic oil to clear the sediment on motor and valve, later, make the change every six months.

4.2

Lubrication

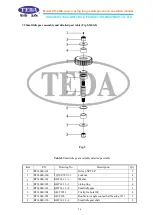

A good grade of multipurpose bearing lubricant which is compatible with expected ambient temperatures is

recommended along with the following lubrication procedures, at the completion of each job prior to

storage

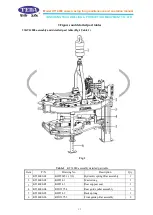

4.2.1 Power input shaft assembly bearings

Unscrew the plug screws on the bearing cover, grease should be applied to these bearings through the

grease fittings in the bearing cap located at the bottom face of the tong.

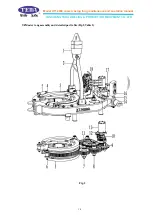

4.2.2 Bearings of big idler gear assembly and triple gear assembly

Grease should be applied to these bearings through the grease fittings in the end of the shaft located at

the top face of the tong. (see illustration below):