Maintenance (Continued)

4. Hold the motor shaft extension

stationary with pliers, and turn the

impeller counter-clockwise until it is

free from the shaft.

5. Remove the adapter (Ref. No. 5)

from the motor by removing the

capscrews (Ref. No. 17).

REMOVAL OF OLD SEAL

INSTALLATION OF NEW SEAL

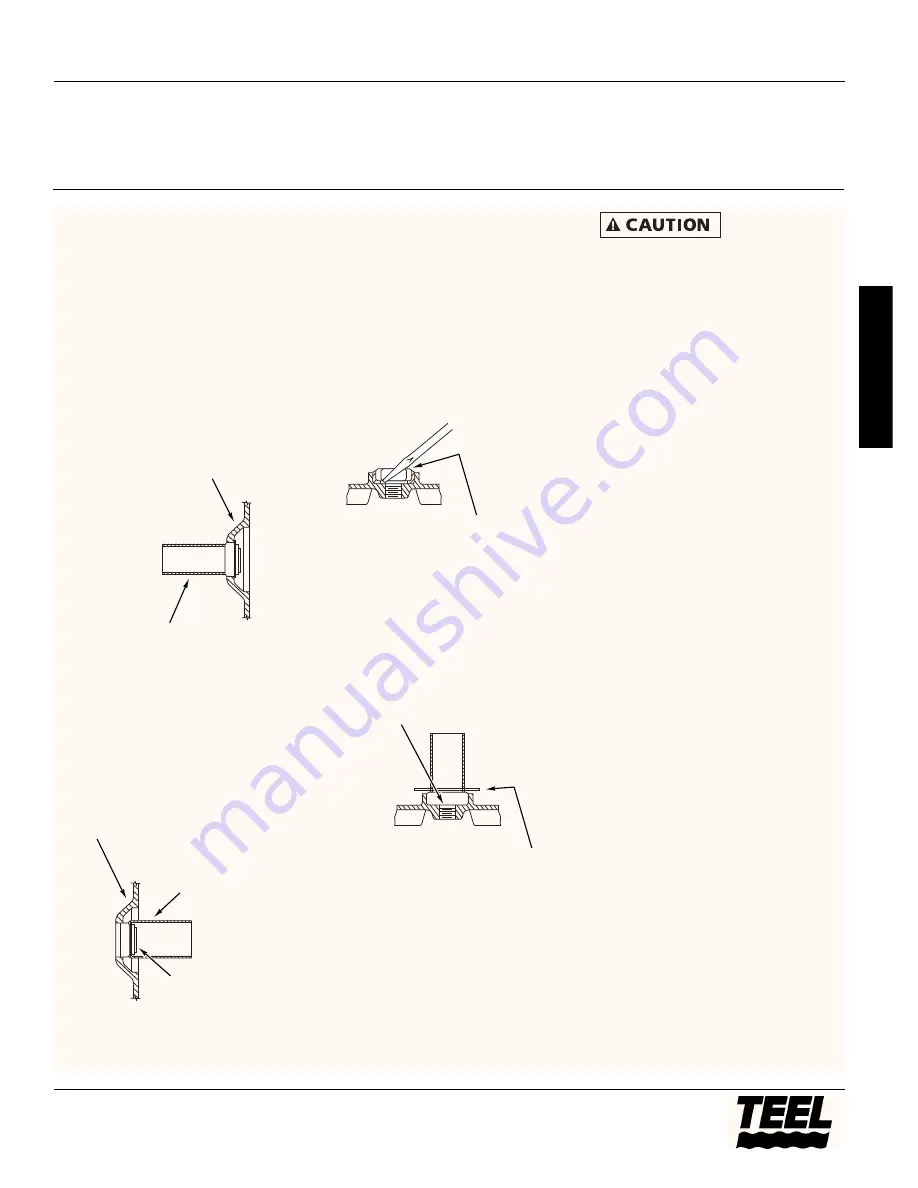

1. Tap the old seal out of the adapter.

Use a piece of pipe or tubing as

shown in Figure 3.

2. Clean the cavity in the adapter.

3. Replacement seal assembly has a dry

lubricant/sealant coating on the

exterior. Do not use any additional

sealing compounds.

4. Press seat into adapter with a tube

or pipe nipple of correct size to

press on the seal rim only (See

Figure 4).

NOTE:

Do not touch or scratch the

polished carbon face of the seal with

the pressing tool.

5. Pry loose the ceramic seal in

impeller, using a screwdriver

between the seat and the cavity in

the impeller (See Figure 5).

6. Lubricate the rubber ring in the

impeller with a soap solution. Press

seat into the impeller cavity

(See Figure 6).

Risk of flooding. If

a tool or pipe is

necessary to press the ceramic seat in

correctly, use a cardboard disc or washer

to protect the highly polished ceramic

surface of the new seal. Remove and

discard disc after assembly.

PUMP REASSEMBLY

Refer to Figure 7, Page 8 for reference

numbers.

1. Loosen shaft extension (Ref. No.

4A), so it may be moved along the

shaft with ease.

2. Replace adapter (Ref. No. 5) on

motor and tighten capscrews (Ref.

No. 17).

3. Make certain the seal faces are

clean.

To set the clearance between the

impeller face and the volute, proceed

as follows:

4. Hold the motor shaft extension

stationary and tighten impeller onto

the shaft.

5. Place volute on adapter without the

gasket and tighten nuts (Ref. Nos. 5,

11, and 16).

6. Push the shaft extension and

impeller toward volute until

impeller touches volute (Ref. Nos.

4A and 10).

7. Tighten set screws (Ref. No. 4B) in

place.

8. Remove volute and install gasket

(Ref. No. 8).

9. Place volute on adapter and tighten

nuts (Ref. No.6). Turn shaft by hand

to make sure impeller does not bind

or drag.

Models 4RH36, 4RH37, 4RH38, 4RH39, and 4RH40

7

Teel Operating Instructions and Parts Manual

E

N

G

L

I

S

H

Figure 4 – Replacing stationary part of

seal

Pump adapter

Tube for pressing

in seal. Press on

flange only

Polished carbon face of

seal. Do not scratch

Figure 5 – Pry out rotating part of seal

from impeller

Pry out rotating part of

seal from impeller

Figure 6 – Replacing rotating part of

seal in impeller

Lubricate rubber ring

with soap solution

Use cardboard disk

or washer to protect

ceramic surface when

pressing new seal into

impeller

Figure 3 – Press out stationary part of

seal

Pump adapter

Tube to press out

stationary part of seal

®