Introduction

5

Introduction

The

ATON

set comprises a

CAN-EZ3A

energy meter and a variable

EHS-R

immersion heater.

These two devices communicate wirelessly with one another. The energy meter and immersion heat-

er are connected at the factory. This means that no wireless connection settings are required. How-

ever, information can be found in chapter

Wireless system

.

The purpose of the

CAN-EZ3A

is to capture energy and calculate surplus output, e.g. in conjunction

with PV systems. Relevant values are transmitted wirelessly to the

EHS-R

, which in turn converts

possible surpluses into heat, instead of exporting them to the mains, which can be a less favourable

option.

The

CAN-EZ3A

is programmed at the factory and this programming is described in more detail in

chapter

Work settings

. This programming can, of course, be changed or replaced with your own pro-

gramming. The energy meter can be fully programmed via the display and control buttons/rotary dial,

but we recommend using the PC software

TAPPS2

for this. Programming generated on the PC can

be loaded on to the energy meter using the supplied micro SD card.

The

EHS-R

immersion heater

does not require any programming/parameterisation.

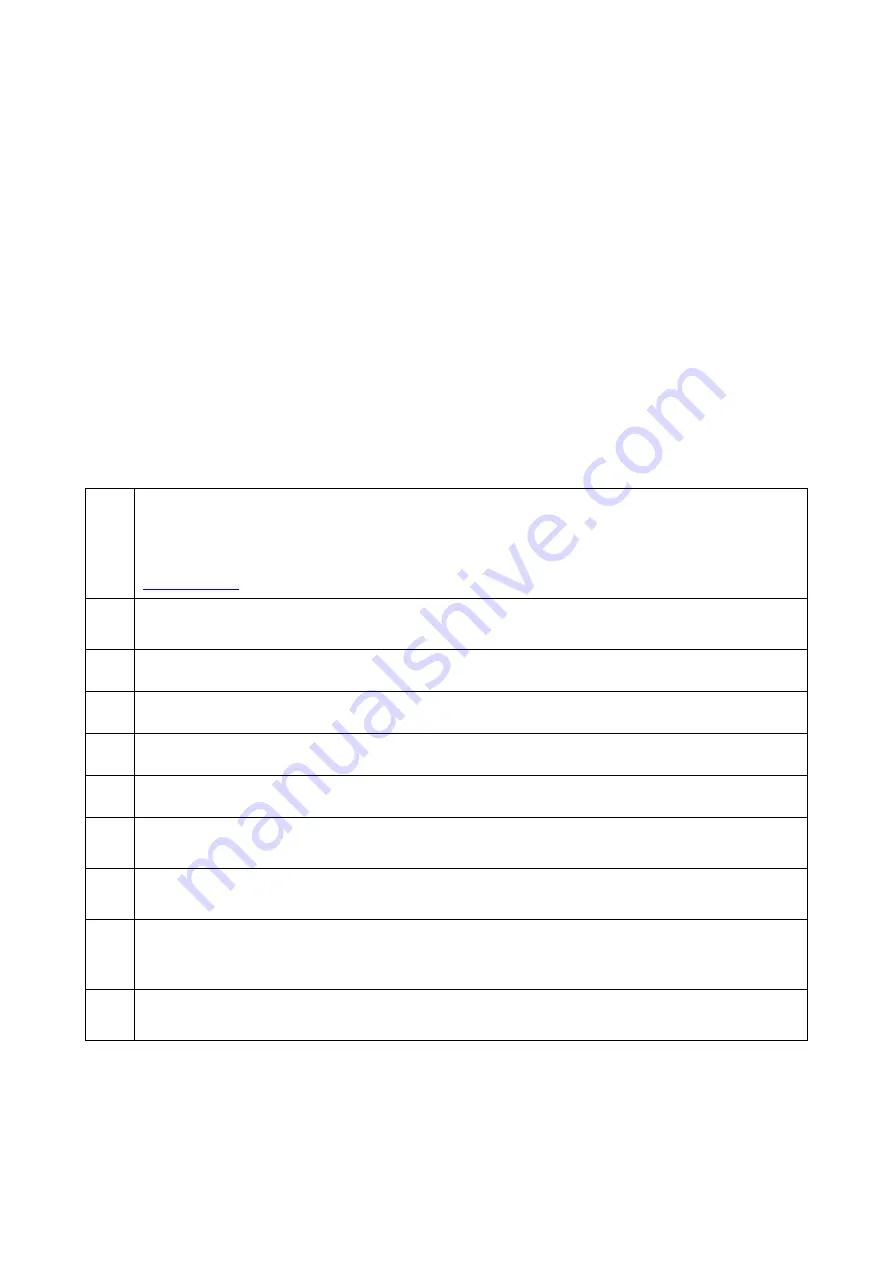

Step-by-step instructions

1

Are the work settings on the CAN-EZ3A suitable for the on-site requirements? (See chapter

"Work settings"

)

If not, adjust the existing programming or generate your own and load it on to the energy

meter. (Instructions for the programming software and available function modules under

www.ta.co.at

)

2

The wireless range (as described in chapter

"Wireless system (x2 wireless)"

) should be

compared with the on-site conditions.

3

Shut down the control cabinet.

4

Installation of the CAN-EZ3A in the control cabinet.

5

Connect a current transformer to the CAN-EZ3A.

6

Connect voltage terminals to the CAN-EZ3A.

7

Snap the current transformer on to phase conductors, taking into consideration the energy

direction. (Current transformer ferrite cores must be clean.)

8

Connect voltage terminals to the phase conductors, taking into consideration the energy

direction.

9

Installation of the EHS-R in the cylinder. (Observe information in chapter "

Installation and

connection – EHS-R immersion heater

", particularly information regarding the electroplat-

ing in the cylinder)

10

As soon as both devices are supplied with power, the wireless connection is established

automatically.